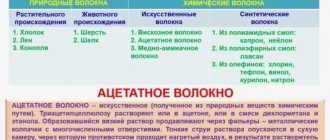

Varieties

There are two main types of synthetics: carbon chain, which in turn is divided into polyacrylonitrile, polyvinyl chloride, polyvinyl alcohol, polyethylene and polypropylene, and heterochain (polyester, polyamide and polyurethane).

The most common synthetic fibers

Acrilan, Roville, Kuralon, Tekmilon, Herculon, lavsan, nylon, lycra, microfiber, acrylic, fleece, polyester, polyamide, polysatin, Oxford, nitron, chlorin, vinol, spectrum, Herculon, etc.

AcrylicAlovaAramidArizonaArselonBiberBiflexBlackoutBolognaBondingVelsoftWindblockVinylDacronDermatinDralonDuspoKapronKashiboKevlarKermelCrimpleinLavsanLycra (Elastane)LakeMedeaMembraneMicrofiberWet silkNylonNeopreneNitronNomexOxfordPANPikachuPolar fleecePolyacrylicPolyamidePolyesterPolyesterPolyester silkSoftSpandexTulleTulleFleeceFukra

Peculiarities

Synthetic polymers are based on low molecular weight organic compounds (monomers), which form long chains as a result of polymerization or polycondensation reactions. The location and configuration of molecular chains and the type of their connection largely determine the mechanical characteristics of polymers.

Artificial and synthetic polymers have a number of specific features. In the first place, it should be noted their high elasticity and resilience - the ability to resist deformation and restore their original shape. Example - polyamide, rubber. Polyurethane thread - elastane, is capable of changing its length by 800% without breaking and then restoring its original size. The presence of long molecular chains in the structure of synthetic materials has determined the low fragility of plastic products. In most cases, the increase in brittleness of some types of plastics occurs as the temperature decreases. Organic materials are almost completely free of this disadvantage.

Certain types of plastics, on the contrary, have high rigidity and hardness. Fiberglass is not much inferior in strength to steel, and a polymer such as Kevlar even surpasses it.

These properties are complemented by high corrosion resistance and wear resistance. Most known polymers have high electrical resistance and low thermal conductivity.

While noting the high operational and technological qualities, we must not forget about the negative aspects:

- Difficulty in recycling. Only thermoplastic material can be recycled and only if properly sorted. A mixture of polymers with different chemical compositions is not recyclable. In nature, plastics decompose extremely slowly – up to tens or hundreds of years. When certain types of plastics are burned, large amounts of highly toxic substances and compounds are released into the atmosphere. This is especially true for plastics containing halogens. The most well-known material of this type is polyvinyl chloride (PVC).

- Weak resistance to ultraviolet radiation. Under the influence of ultraviolet rays, long polymer chains are destroyed, the fragility of products increases, strength and cold resistance decrease.

- Difficulty or impossibility of joining certain types of synthetic materials.

The chemical properties of polymers show their high resistance to aggressive substances, but in some cases makes it difficult to use adhesive compositions. Therefore, for thermoplastic polymers, the welding method is used - connecting heated elements. Some substances, for example, fluoroplastics, are not subject to connections at all, except mechanical ones.

What is the difference between synthetic fabrics and artificial ones?

Most people confuse artificial and synthetic materials. In fact, such textile products, being unnatural, have significant differences from each other. The first fabrics were made from threads obtained artificially from natural raw materials. Artificial fabrics are obtained by processing proteins, metals, and wood. Synthetic materials are made from raw materials obtained through chemical synthesis of substances not found in nature.

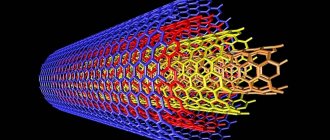

Crystal fabric

With the development of industry, manufacturers have learned to create nanomaterials with unique properties. Thanks to the constant improvement of technological processes, modern materials obtained artificially are often significantly superior to natural ones in terms of operational and external characteristics. Despite this, they are still separated from natural fabrics.

Classification of synthetic polymers

There are several classification groups of polymers, depending on the defining feature. First of all, this is:

- Artificial polymers created on the basis of natural organic polymers (cellulose - celluloid, rubber - rubber);

- Synthetic polymers based on synthesis from low molecular weight compounds (styrene - polystyrene, ethylene - polyethylene).

According to the chemical composition, the division is as follows:

- Organic, containing predominantly hydrocarbon chains;

- Organoelement, including inorganic atoms (silicon, aluminum) in organic chains. The most striking example is organosilicon compositions.

Depending on the types of chains of molecular composition, the following types of polymer structure can be specified:

- Linear, in which the monomers are connected in long straight chains;

- Branched;

- With a mesh structure.

All polymer compounds are characterized differently with respect to temperature. Thus, they are divided into two groups:

- Thermoplastic, for which the effect of temperature causes reversible changes - heating, melting;

- Thermosetting, irreversibly changing its structure when heated. In most cases, this process occurs without a melting step.

There are several other types of classification of polymers, for example, according to the polarity of molecular chains. But this qualification is necessary only for narrow specialists.

Many types of polymers are used independently (polyethylene, polyamide), but a significant amount is used as composite materials, where they act as a connecting element between an organic and inorganic base - plastics based on glass or carbon fibers. You can often find a combination of polymer - polymer (textolite, in which the polymer fabric is impregnated with a polymer binder).

If you find an error, please select a piece of text and press Ctrl+Enter.

Why is synthetics worse than natural fabrics, what are its disadvantages?

Different types of synthetics have certain disadvantages. However, they all have common negative features that distinguish them from natural fabrics:

- ability to cause skin irritation;

- tendency to accumulate static electricity;

- unsatisfactory absorbent properties;

- difficult air exchange, as a result of which frequent use of synthetic clothing is not comfortable enough;

- predisposition to absorb unpleasant odors.

History of the appearance of dyes

Since ancient times, people have used natural dyes to give fabrics a certain color. For example, indigo dye was obtained from plants containing the substance “indican glycoside”. The plants were soaked until the natural fermentation process began. The fermented liquid was poured into special ditches, where it oxidized. It was this dye that was originally used to dye denim. A chemical analogue of indigo was invented only at the beginning of the last century.

Another natural dye is purple. It was obtained from the liquid secreted by the mollusk Murexbandaris. Another dye was obtained from the roots of the Madder plant. The Romans and Egyptians used ocher, which consists of iron oxide with clay.

Also, plants such as turmeric and sage were used to dye fabrics.

It must be said that the disadvantage of natural dyes is the uneven coloring of fabrics. In addition, their production was expensive and labor-intensive.

Industrial dyeing of fabrics dates back to the second half of the 18th century with the invention of yellow dye - quercitron. By the end of the 18th century, a new method of painting appeared - using chrome.

However, people wanted to wear more and more varied and colorful fabrics. By the end of the 18th century, picric acid began to be widely used to dye fabrics yellow. As for bleaching, already at the end of the 18th century, chemists actively used chlorine for this. By the end of the 19th century, synthetic dyes fuchsin (bright red) and mauvais (purple) appeared.

And by the beginning of the 20th century, artificial dyes already outnumbered natural ones. The main dye-producing countries of that time included Germany, England, and France. In Russia, before the First World War, artificial dyes were supplied mainly from Germany. Only during the war did Russia begin to develop its own production at a rapid pace.

Modern industrial dyes

Today there are countless dyes. Of the natural dyes, manufacturers use only loggerhead and cochineal. Artificial fabric dyes are more durable than natural dyes, not to mention the endless variety of colors and shades of artificial dyes.

To dye fabrics, dyes and pigments are used, which differ in the way they act on the fibers of the fabric. Dyes penetrate the fibers of the fabric, forming a strong bond with them, and the pigments simply settle on the surface of the fabric without penetrating into its structure. To fix the pigment to the fabric, certain chemicals are used to allow the color to adhere firmly to the surface. The color fastness of the fabric depends on these substances.

Various dyes are used in industrial production:

- active,

- anionic,

- dispersed,

- straight,

- vat,

- acidic,

- aniline.

The type and composition of the dye is selected based on the type of fabric that needs to be dyed.

Active dyes are used for cotton, viscose and linen, disperse dyes are used for synthetics. Aniline dyes can be used to dye cotton, silk, wool, and leather.

Many factories in Russia produce dyes: the Davydov Center, the Moscow enterprises Gamma, Unikhim.

Screen printing on textiles

Decorating clothes using drawings has been popular all over the world for many years. At first, the application process was complex and more labor-intensive, manufacturers offered paints in limited colors, and application of complex multi-component designs was technically impossible. However, over time, paint manufacturers began to offer products that facilitate the technological process, are easy to use and allow you to apply complex and colorful designs that last a long time on clothing.

Modern manufacturers offer a wide range of inks for professional printing on fabrics. Fabric printing uses screen printing or silk-screen printing technology, which is used in the textile industry for printing fabrics or for printing on finished clothing (for example, T-shirts or caps).

For screen printing, special inks are used that have the property of “sticking” to the fabric. In addition, such paint must have thixotropy (the ability to change viscosity with temperature changes and stirring).

There are the following types of inks for printing on fabric:

- solvent (dries quickly and is used for applying images to fabrics made of synthetic materials and finished products);

- water-based (they don’t dry as quickly, but they can be applied to any surface, including over other paint);

- plastisol (the paint requires exposure to temperature to dry, is easy to apply and adheres well to textiles, suitable for both synthetic and natural fabrics, looks good even on dark surfaces, and is also safe to use);

- chemically curing (resistant to abrasion and external factors);

- paints with ultraviolet polymerization (harden under the influence of UV rays in a short time, the image is bright and resistant to abrasion, but paints are expensive, and their use requires a complex technological process).

Among the main manufacturers of screen inks for printing on fabric are SICO, KFG, Sericol, Marabu, Union Ink.

Also, in addition to the direct method of printing with screen inks, there is a thermal transfer method, that is, the image (transfer) is first printed and then transferred to the fabric.

Positive qualities of synthetic fiber fabrics

What positive features are characteristic of synthetic materials? The strengths of synthetics include:

- availability;

- room for care;

- durability;

- color fastness;

- low creasing;

- dimensional stability;

- ease;

- ability to dry quickly.

Whatever synthetic material is used for sewing clothes, you don’t have to worry about the product maintaining its original properties throughout its entire service life. Allergy sufferers, pregnant and lactating women and children should use wardrobe items made from such fabrics with caution.

Basic physical and chemical properties

Various polyamides have similar basic properties. All of them are rigid materials with high tensile strength. PAs are characterized by high wear resistance. The high softening temperature allows the material to withstand the steam sterilization process at 140 °C. They do not lose elasticity in low temperatures.

All these properties make the temperature range of use of PA very wide.

Another property of polyamides is their high water absorption capacity, which when dried easily returns the material

to the original level. All types of PA are characterized by high strength during shearing and at the point of impact. They can be easily welded using the high-frequency method. A high degree of vapor permeability and a low level of gas permeability make polyamides an indispensable material for vacuum packaging.

The entire complex of basic properties of PA is based on the concentration of hydrogen bonds, which are per length of the macromolecule. The higher this concentration, the higher the temperature during melting and glass transition of the material. Along with this, strength characteristics increase, as well as heat resistance, water absorption and solubility data with the participation of polar solvents. In this case, a decrease in dielectric characteristics, stability of properties and dimensions is observed.

PAs have proven themselves to be excellent anti-friction materials. Antifriction properties are easily increased by introducing special additives.

The disadvantages of PA include relatively high water absorption, low dielectric properties, instability to ultraviolet radiation and flammability.

Types and properties of synthetic fabrics

Fabrics made from synthetic fibers are divided into varieties depending on their composition. The raw materials contained in them determine their properties. This group of matter is divided into 2 subgroups: carbon-chain and heterochain. The first includes fabrics in the manufacture of which hydrocarbons are used: polyethylene, polyacrylonitrile, polypropylene, polyvinyl chloride and polyvinyl alcohol. The second subgroup consists of fabrics that, in addition to hydrocarbons, contain nitrogen, chlorine or fluorine: polyester, polyurethane and polyamide.

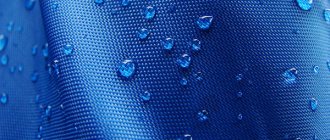

Polyethylene and polypropylene fabrics for technical applications

The cheapest fibers obtained from polyethylene and polypropylene raw materials are called “polyolefion”. The main purpose of these types of synthetics is the production of carpets and materials for technical use. Fabrics containing polyethylene and polypropylene have the following properties:

Polypropylene fabric

- high strength;

- wear resistance;

- resistance to mold and other pathogens;

- moisture resistance (when combining polypropylene with polyethylene);

- lightness - thin polyolefion fibers are the lightest among all types of synthetics;

- excellent thermal insulation;

- low extensibility.

Polyethylene film

The weakness of this type of synthetics is the lack of fire-resistant qualities. Basically, such materials are used for the manufacture of packaging and containers (in particular, bags).

Polyacrylonitrile instead of wool

Polyacrylonitrile fibers are made from polyacrylonitrile (a petrochemical product obtained from natural gas and commonly called acrylic), which is briefly called PAN. In terms of its mechanical properties, this material is close to woolen fabrics, which is why it is often called artificial wool.

Polyacrylonitrile fabric

This matter has the following characteristics:

- UV resistance;

- heat resistance - retains its qualities at temperatures up to 130 degrees;

- dimensional stability;

- moisture resistance;

- strength;

- softness;

- ability to dry quickly;

- resistance to damage by pathogenic microorganisms, as well as the action of acids, alkalis, gasoline, acetone;

- color fastness.

Acrylic is a rigid, non-hygroscopic, airtight, quickly abrading and easily electrified fabric. During use, pellets form on the surface of this material, and due to its ability to absorb fats, difficult-to-remove stains appear on it.

Polyvinyl chloride and polyvinyl alcohol synthetics

Polyvinyl chloride fabric is a fabric made from tightly woven polyester, nylon or lavsan fibers, which are covered with a layer of polyvinyl chloride (PVC). Polyvinyl alcohol (PVA) fabrics are woven from fibers obtained from solutions of polyvinyl alcohol. Brief information about the characteristics of these types of synthetics and where they are used is presented in the table:

PVC fabric

| Varieties of synthetics | Advantages | Flaws | Areas of application |

| Polyvinyl chloride | Elasticity, density, resistance to increased mechanical stress, moisture, sun and heat resistance, accessibility, non-oxidation, long service life. | Air tightness, toxicity of decomposition products, release of dangerous hydrogen chloride during combustion, impossibility of complete decomposition, accompanying the production process with harmful emissions. | It is used for the manufacture of trampolines, gymnastic mats, wrestling flooring, professional footwear, hiking clothing, fishing equipment, mattresses for pools, inflatable swimming equipment, awnings, tents and other frame structures, banners and streamers, stretch ceilings. |

| Polyvinyl alcohol | Strength, abrasion resistance, low thermal and electrical conductivity, resistance to ultraviolet radiation and damage by pathogens, non-flammability, availability, hygroscopicity comparable to cotton, low pilling, aesthetics. | Low resistance to dirt, tendency to shrinkage and loss of strength upon contact with water. Unlike other chemical materials, polyvinyl alcohol synthetics are less resistant to chemical influences. | Used for sewing clothes and underwear. With the addition of cotton and viscose it is used for the production of hosiery. |

Popular polyester

Polyester

Polyester refers to a synthetic fabric made from the melt of polyethylene terephthalate and its derivatives, which accounts for about 65 percent of the textile market. Polyester fabric is characterized by:

- wear resistance;

- color and shape stability;

- resistance to unpleasant odors, the action of aggressive solutions, as well as damage from pathogens;

- low pillability;

- dust and dirt resistance;

- ease;

- ability to dry quickly;

- crease resistance;

- availability;

- ease of care;

- moisture resistance.

Among the disadvantages of fabrics made from this type of synthetics are:

- difficult air exchange in the fibers;

- rigidity;

- poor paintability;

- electrification;

- risk of skin irritation.

Elastic polyurethane

In the list of fabrics made from synthetic fibers, polyurethane occupies a special place. Polyurethane threads obtained from polyurethane rubbers are not used in their pure form. They are used as a frame on which other threads are wound. Materials containing such raw materials have a number of advantages:

- ability to restore shape after 6-7 times stretching;

- resistance to abrasion and ultraviolet rays;

- crease resistance;

- color fastness;

- resistance to chemicals.

Spandex

Among the disadvantages of polyurethane are:

- low heat resistance;

- non-hygroscopic;

- lack of free air exchange in the fibers.

These raw materials are used to make materials for sewing clothing, as well as fabrics for technical and medical purposes. Polyurethane is used to make a water-repellent layer in products intended for divers, divers, fishermen, and tourists.

Fabrics made from polyamide fibers

Polyamide fabric

What are such materials made from? The function of raw materials in the production of fabrics from polyamide threads is performed by compounds including the amide group CONH. Polyamide-based fabrics are characterized by:

- high strength;

- dimensional stability;

- ease;

- resistance to damage by various microbes;

- ability to dry quickly.

Fabrics made from polyamide fibers have low heat resistance, a tendency to yellow when in contact with sweat and ultraviolet radiation, electrification, low hygroscopicity and the ability to retain heat. Thin tights and leggings are made from this material.

Industrial Applications

Almost all types of polymers are widely used in the following areas:

- light and textile industry. PAs are used for the manufacture of various synthetic and blended fabrics. They are used to produce carpets, rugs, artificial fur and various types of yarn. Polyamides are used in socks and hosiery production;

- rubber industry. Polyamides are involved in the creation of cord threads. They are used to make ropes, filters, conveyor belts and fishing nets;

- building sector. Various fittings, pipe products, and antiseptic coatings for various surfaces are produced from polyamides. PA protects metal products from rust;

- mechanical engineering, aviation and shipbuilding industries. Polyamides are indispensable as a starting material for the production of various parts and hardware. They are components for glue and varnish.

- In addition, polyamides have found application in the food and medical industries. Some parts for production equipment, artificial substitutes for veins and arteries, various prostheses and surgical threads are made from them.

Artificial fabrics and synthetics. Easy, original, economical!

Man-made fibers on a natural basis

Viscose is a fiber that belongs to artificial fibers, but is of natural origin. It is produced from plant and wood cellulose, which is pressed in a special way.

Viscose fiber has the following characteristics:

- softness, tenderness, subtlety;

- hygroscopicity (the ability of a material to absorb and retain moisture);

- good breathability and moisture absorption;

- color intensity.

When viscose fibers are added to cotton yarn, the rate of moisture absorption is greater than that of cotton. In addition, viscose fibers do not create static electricity, so clothes do not stick to the body when walking.

Acetate silk is a worthy replacement for natural fiber

In terms of the shine of the threads and the smoothness of the surface, acetate silk is even superior to natural silk! But fabrics made from natural silk fibers are superior in their wet strength and elasticity. The fact that acetate silk cannot be dyed with dyes suitable for cotton or wool fibers forced manufacturers to develop a special group of dyes. They are also used for dyeing products made from mixtures of silk acetate with other materials. At the same time, things turn out to be very original, distinctive colors and shades.

Both fabrics (natural and artificial) attract with their smooth surface and shine; they do not wrinkle due to deformation, do not wear out during long-term use, and retain their original color. This external similarity of two types of silk fabrics allows you to replace natural expensive material with acetate silk. Acetate silk is not even produced from cellulose itself, but from its derivative - the substance “cellulose ether acetate”.

Acetate silk has various properties:

- transmits ultraviolet rays,

- it does not absorb moisture,

- does not swell like natural silk fiber when wet.

The fact that swelling does not occur contributes to less loss of strength of acetate silk when wet compared to other types of artificial silk. The positive characteristics of this material also include its low thermal conductivity and electrical insulating properties.

This type of silk is very picky about washing; it should be washed in the delicate mode of washing machines, or by hand at a temperature of no more than 30 C. It is recommended to dry it in room conditions, flattened.

Acetate silk dries very quickly; ironing is not necessary. And if the need arises, then do it very carefully with a non-hot iron from the wrong side of the product.

When weaving acetate silk, a filament thread is used, which is given a hollow, shaped, crepe twist. Crepe yarn increases the elasticity of the fabric without adding grain to the surface of the material, and is used to maintain the shape of the fabric. This type of silk is used for sewing light sundresses, dresses, blouses, men's shirts, and clothes for children.

Triacetate silk fabrics are characterized by:

- high degree of crease resistance,

- maintaining dimensions,

- resistance to high temperatures when ironing,

- ease,

- good drapability.

The disadvantages of this type of silk include:

- instability to friction,

- electrification,

- low strength indicators,

- significant movement of the threads at the seams.

, triacetate silk fabrics are produced bleached, printed, and sometimes plain-dyed.

Among artificial fabrics, the fabric known and popular is polyamide . This is a very light, quick-drying, breathable, wear-resistant fabric that perfectly retains its shape. Polyamide has a rough, smooth, matte or shiny surface. Polyamide is most often used in the manufacture of products that come into direct contact with the body. Lace and sewing are also made from polyamide.

Among the properties of polyamide it is necessary to note:

- ease;

- highly elastic;

- crease resistance;

- strength and durability;

- instantly absorbs moisture, but dries immediately;

- not subject to shrinkage.

This material does not attract moths, does not rot at all, and is resistant to sea water.

Synthetic fabrics are elastic and practical

The leader among synthetic fabrics is polyester . These terms refer to polyester fibers and materials. Polyester has great strength and is resistant to wear. It holds its shape perfectly, does not wrinkle, is resistant to ultraviolet radiation, and is slightly hygroscopic. Used in the manufacture of swimwear: swimming trunks, swimsuits.

Fashionistas who monitor their health and figure, engage in sports and fitness, have probably encountered another representative of synthetic materials - elastane .

All form-fitting clothing that is supportive but not restrictive is made with elastane fibers. When stretched, the fibers of this material exceed their original dimensions by 7-9 times. After removing the deformation loads, the fibers are completely restored.

Lycra is a very dense, delicate, rough fabric, pleasant to the touch, which has a matte, noble shine with a slight dusting . It is able to support and fit without interfering with freedom of movement, providing complete comfort. Lycra clothing is highly breathable, instantly absorbs moisture and dries quickly. The elasticity of this material is not affected by numerous washes. This fabric seems to be specially created for the production of lingerie, tight-fitting sportswear, open and tight dresses and swimsuits.

Spandex is a lightweight synthetic fiber. It is used in the manufacture of clothing for physical education and sports. This material is the result of a complex chemical reaction of certain substances with polyester.

The material has found its application in sewing bicycle trousers and swimwear, underwear and hosiery.

Manufacturers of polyamides

The growth in demand for PA and compounds in Russia is based on the development of polyamide-consuming industries, import substitution,

the need to overcome the consequences of the financial and economic crisis and increase consumption potential.

The well-known French company Arkema Incorporated holds a competitive position. It has already increased the production capacity of polyamides under the Orgasol brand at the plant in Mont. by 40%.

The total world production of polyamide is several million tons.

Based on the marketing research “Polyamides Market in Russia 2010-2020.” Indicators and forecasts”, according to a comprehensive analysis of this segment, the situation on the polyamide market is as follows.

Phone recycling

Phone recycling

- a necessary thing in modern society.

Problems with silting of pipes are present in all public utilities. more about this in the article.

Do you have a lot of newspapers? Using this https://greenologia.ru/othody/bumazhnye/vtorichnogo-rossijskogo-rynka.html link you will find out where you can donate them and get rid of garbage forever!

The Russian polyamide market, contrary to the indicators of industrial flotation, is characterized by stagnation. The polyamide market is characterized by the predominance of products from Russian enterprises. About 70% of the total volume is spent on exports. The Samara region achieved the best production indicators. Germany holds the leading position in the field of import supplies. The figures exceed 51%, and the leading supplier of polyamides, BASF SE, accounts for 32%.

More than 45% of Russian polyamides are purchased by China. The largest acquirer is KUIBYSHEVAZOT TRADING.

Recycling

Among solid polymer waste, polyamide waste is of significant importance. Most often they are formed during the production process

and processing of nylon and anide fibers. A significant part of the secondary PA raw materials is occupied by products that are no longer in use. The quantitative composition of fiber production waste is almost 15%. Polyamide is a rather expensive material and has valuable chemical and physical-mechanical properties. The rationality of its processing is of particular economic importance.