Modern technologies have affected all spheres of human life. The best example of how they are developing is the textile industry: humanity has learned to produce synthetic fabrics.

Viscose is a type of artificial fabric made from cellulose. This type of canvas is obtained by processing wood raw materials. Synthetic fabrics are made from polymers obtained through chemical reactions. The raw materials for the material are petroleum products, coal, gas. As a rule, sportswear or things necessary for use in extreme situations are made from synthetic fabrics.

Advantages and disadvantages of synthetic fabrics

Synthetic material has its advantages and disadvantages. Despite the abundance of natural fabrics, there are a number of advantages of synthetic material.

- Lightness of fabric. Unlike natural materials, synthetic fabric is lightweight.

- Durability. Clothing made from synthetic material is less susceptible to wear and tear and retains color fastness well. This is achieved through special processing of matter. That's why things can be worn for a long time without fear of them fading. However, some species deteriorate when exposed to ultraviolet rays.

- Fast drying. Almost all synthetic materials do not absorb much moisture, and drying does not take much time.

- Price. The low price of the material is achieved due to the low cost of the original product. It is profitable for enterprises to produce such fabrics, which is why their production volumes are increasing every year.

The industry is developing every day. Fabric manufacturers can change the characteristics of the fabric taking into account the wishes of large customers.

The biggest disadvantage of such materials is that they can negatively affect health. Synthetic fabric becomes electrified due to the fact that it accumulates static electricity. A person may have an individual tolerance for this tissue. It practically does not absorb moisture, therefore, it is not a very hygienic material. Synthetics are not breathable, so underwear made from polyester or spandex is not very comfortable for everyday use.

On the other hand, in bad weather, synthetic fabric will be extremely useful - it can protect a person from precipitation better than natural fabric.

Recommendations for product care

Moisture is poorly absorbed, so they dry quickly. They have straightening properties, no ironing required. Before use, you should carefully read the labels on clothing.

Washing in a washing machine:

- Delicate mode or “synthetic” program.

- Spin – eight hundred, thousand revolutions.

- Temperature - forty to sixty degrees.

- Use special detergents.

- Bleach should not be used.

- Adding air conditioning will help when things get electrified.

Manual:

- Wash in warm water;

- Do not wring out - let the moisture drain on its own.

Ironing should be done when the material is damp, at a temperature of one hundred to two hundred degrees.

Production Features

The first patent for the production of synthetic fabric was registered back in 1930. First, they learned to isolate polyvinyl chloride fibers, then German scientists were able to obtain polyamide. This material became known as nylon. Its production was put on the assembly line only in 1939.

In the Soviet Union, synthetic clothing began to be produced only in the late 60s. At first it was simply a cheap substitute for natural fabric. Only many years later they found proper use for it: they began to produce workwear that was distinguished by high wear resistance characteristics and could protect a person from adverse environmental factors.

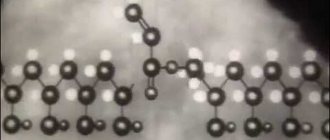

Artificial and synthetic materials differ in the specifics of production, as well as in the cost of raw materials. Synthetics do not require large expenses. When making fabric, fiber is synthesized from low molecular weight compounds. To produce a material, the raw material must be melted or dissolved. Afterwards, the thread can be separated from the viscous material. The thread can be single, complex or twisted in the form of a tourniquet. Also, individual parts of clothing and shoes can be made from the molten material.

Story

Everyone knows what fabrics are made from - from different types of fibers. Until the middle of the last century, we used exclusively natural fabrics: cotton, linen, silk, etc. In the 1940-1950s, we learned to produce artificial fibers (viscose, acetate).

- The production of fibers from molten synthetic polymers began to develop in industrialized countries in the 1940s to 1970s. During this period, such fibers only partially replaced natural fibers and were used as a supplement.

The first such fiber was nylon. It was invented by DuPont employee Wallace Carothers in 1935. The new material was particularly durable and had low production costs and quickly gained popularity.

- Since the 70s of the last century, the production of synthetics has increased greatly, and canvas made of synthetic fibers has become widely used as an independent material.

What are synthetic textiles made from?

Today there are many types of synthetic fibers. Specialists are constantly producing new varieties of material. However, for convenience, they are divided into two groups, each of which has its own characteristics.

Carbon chain synthetics

Hydrocarbons are used in its production. This variety combines the following list of fabrics:

- polyethylene;

- polyacrylonitrile;

- polypropylene;

- polyvinyl chloride;

- polyvinyl alcohol.

Heterochain synthetics

This type of fabric is made not only from hydrocarbons, but also from other chemical elements. These can be nitrogen, chlorine, fluorine. Elements help improve the characteristics of matter.

This group includes the following fabrics:

- polyester;

- polyurethane.

- polyamide.

Thanks to these substances, things based on heterochain synthetics add additional qualities to the usual characteristics, which are indispensable when sewing workwear.

Synthetics - a triumph of the chemical industry

The axiom “Natural fabrics are good, but synthetics are bad” is clearly embedded in the minds of many people. At the same time, most people call all materials except cotton, linen, silk and wool synthetics.

It is important to know! All non-natural fabrics are divided into two large groups - artificial and synthetic. The first ones are made from natural components - cellulose, proteins, glass. Synthetic materials are based only on polymers that do not exist in nature.

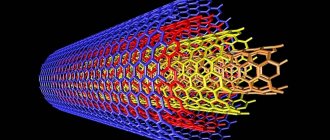

Synthetic fibers are obtained through the synthesis of ethylene, benzene or phenol produced from natural gas, oil and coal.

The history of synthetic fabrics began a little more than half a century ago, when, shortly before World War II, the leading chemist at the American DuPont factory, Wallace Carothers, synthesized a new material called “nylon.”

This shiny, smooth fabric, pleasant to the touch, immediately turned out to be in demand for the production of women's stockings. During the war, nylon was used for the needs of the army; it was used to make fabric for parachutes and camouflage netting.

Already in the late 40s - early 50s of the 20th century, the era of synthetics began - nylon, nitron, anide, polyester and other fibers appeared on the textile market.

The chemical industry does not stand still, and now the number of items of synthetic fabrics has exceeded one hundred. Modern technologies make it possible to obtain materials with predetermined properties.

Types and names of synthetic fabrics

So, the textile industry at this stage of its development makes it possible to produce a variety of types of synthetic fabric. But how not to get confused in such an assortment and find out which fabric meets all the necessary criteria? Here are brief characteristics of the most popular varieties of synthetics.

- Lavsan

Has high wear resistance. The fabric does not shrink and can withstand strong temperature changes, up to + 115 degrees. Keeps its shape for a long time. The material is hard to the touch and does not allow water to pass through. The canvas is most often used in the manufacture of curtains. Much less often it is added to natural raw materials for the production of suits - this allows to increase the wear resistance of products.

- Fleece

Made from synthetic fiber. In appearance it resembles natural wool. Very soft, warm material. It is elastic and breathable. The material is easy to care for, easy to wash and clean. The main thing is that it does not need to be dried and ironed for a long time, which significantly saves time. The fabric is often used in the production of children's clothing. The disadvantage is the rapid loss of shape due to the fact that the item stretches during everyday wear. Fleece can accumulate static electricity.

- Polysatin

Made with the addition of cotton or polyester. The material has a number of advantages. It is easy to wash, does not wrinkle, does not lose shape, and has a shiny surface. It is often used in the production of bedding sets, curtains, and for furniture upholstery. Fashionable and popular bed linen “with a 3D effect” is often made from this type of fabric.

- Acrylic

This is a fabric that looks like wool, but it is much more practical than natural fiber. Retains its shape for a long time and does not allow moisture to pass through. The material is not exposed to ultraviolet rays, is easy to clean and does not shrink. It is also used in combination with wool.

Acrylic is used for sewing outerwear. In combination with wool, it is also used to make children's mattresses, since this fabric is not able to absorb water. When combined with natural fibers, it gives things strength. Acrylic does not form pellets and is able to hold its shape for a long time. However, it also has a small drawback - things made from this fabric are highly electrified. Acrylic is often added to knitting threads.

- Dyneema and Spectra

In this group, there are two types of fibers - polyethylene and polypropylene. They are the lightest in the synthetic fabric category. Such a canvas cannot be drowned in water. It is heat resistant. The material cannot be stretched and is resistant to any weather changes.

Withstands temperatures up to +115 degrees. Widely used in the production of tourist and specialized clothing, for example for fishermen, skiers, rock climbers, and hunters. The material is also used for the manufacture of underwear and hosiery. However, for this purpose, fabric made from natural fibers must be taken.

Product care

- Wash products made from synthetic fibers at a temperature of 30-40 degrees. Polyester - up to 60 degrees. For white items, universal powders are used; for colored items, special powders are used for thin and colored fabrics. You can choose any washing mode depending on the degree of contamination and type of fabric. You can spin it in a washing machine, reduce the number of revolutions to a minimum.

- Such products cannot be dried in the machine, since the resulting wrinkles will then be very difficult to smooth out. Drying outdoors or in a well-ventilated area is preferable. It is forbidden to dry synthetics on radiators.

- Iron synthetics using the “silk” setting. Nylon is ironed at a minimum temperature without wetting.

Publications on synthetic fabrics

Bottom line

Every year, the production of products made from synthetic fabrics is growing due to the fact that the raw materials are cheap. The functional characteristics of products and their appearance are also improved.

Synthetic items have high heat-protective properties. They have low hygroscopicity, high hydrophobicity and are quite durable. They may not be as comfortable as natural fibers. There is a lot of controversy about their safety for health. But the above properties allow them to remain among the promising options for use in the textile industry.

Application

Some types of synthetic fibers are not used in their pure form; they are mainly added to other fibers (natural cotton, linen, wool) to obtain fabrics with improved characteristics.

- So, adding even a small percentage of elastane or lycra will make the fabric more elastic. These fabrics and knitted fabrics are used to make women's and men's casual, sports and outerwear, stockings and other products.

- Polyacrylonitrile fiber is used to make artificial fur, knitted fabric, carpets and floor coverings, and blankets.

- Polyester thread is used to make fabrics and knitwear for the production of clothing, home textiles and materials for technical purposes. Staple fiber is added to cotton, flax, wool and durable materials are obtained from which all groups of clothing, carpets, and artificial fur are produced. Felt made from polyester is in many ways superior in quality to natural wool felt.

TM Modellini offers stylish knitwear for the whole family. High quality products from interlock and knitwear, rich colors and affordable prices will certainly suit your taste.

Such a changing technological world

In the modern media space, the role and place of images in synthetic arts cannot be overestimated. Moreover, its digital form is rapidly evolving. And if you consider how much digital computer technology is present in traditional academic disciplines today, you can see how the lines between established forms of art and multimedia “masterpieces” are blurring.

Artificial

Fabrics obtained from natural substances (proteins, metals, glass, cellulose). In 1890, the first production of artificial fibers from cellulose was founded in France. At first, fiber was used as an additive to natural ingredients, but by 1970 its quality not only improved, but also began to impart additional properties to products (heat resistance, strength, elasticity), which contributed to its popularization.

- Viscose Fabric with properties close to natural.

Made from wood cellulose fibers. Depending on the production technology, it can have the texture of cotton, wool, silk and even linen. The material wears well and is pleasant to the body. Loses strength when wet. - Acetate silk The fabric was named for its external similarity to natural silk.

The smooth flowing fabric is easy to wash, hardly wrinkles and drapes well. Among the useful properties is immunity to dust. Does not tolerate high temperatures when ironing. - Fabric with casein fibers Casein fibers are not used in their pure form due to impracticality, but in combination with the addition of viscose or other fibers they are used to make home textiles: curtains, bedspreads, blankets, etc.

Such fabrics have excellent hygroscopicity, are soft and do not wrinkle. The disadvantage is low strength. - Acrylic Fabric, for which natural gas is used as a raw material, has properties similar to wool - soft and warm.

Sometimes it is called artificial wool. Disadvantages: poor air permeability, high creasing and loss of strength when washed.