Production of nonwoven materials. Part 1

SECTION “KNITTING PRODUCTION. PRODUCTION OF NONWOVEN MATERIALS.”

TOPIC 4.2.1.1. “GENERAL CHARACTERISTICS OF NONWOVEN MATERIALS. PRODUCTION TECHNOLOGY."

TOPIC PURPOSE:

- Introduction to the class of nonwoven materials

- Studying the characteristics of nonwoven materials

- Study of nonwoven materials production technology

LEVEL OF COMPREHENSION

:

- Know the structural features of nonwoven materials

- Know the general technology for the production of nonwoven materials

- Understand the impact of nonwoven properties on application

CONTROL OF ABSORPTION:

- Oral questioning or written knowledge control before the start of classes

- Consolidating acquired knowledge when performing independent work

- Performing laboratory work

GENERAL CHARACTERISTICS OF NONWOVEN MATERIALS

Nonwovens are textile products that resemble fabric in appearance. Non-woven

are textile fabrics made directly from fibrous canvas, layers and systems of threads, other textile and non-textile materials, low-density (frame) fabrics, fastened in various ways (mechanical, physical-chemical, combined), but without spinning and weaving processes or from yarn without weaving process. The basis of non-woven fabrics are fibrous canvases, layers of threads, loose structure fabric, knitted fabric and various combinations of these materials.

In addition, textile materials, polymer films, and meshes can be used as elements of the fabric base. Often, to increase the strength of the fibrous canvas, a frame in the form of a transverse system of threads is placed on its surface or between layers; mesh of warp and weft threads laid on top of each other; sparse tissue; polymer film.

The structure can be fastened in various ways - knitting with threads, needle punching, gluing, felting. The main applications are glue (dry and wet) and mechanical (knitting and stitching, needle punching and felting) production methods.

The first attempts to produce textile materials using any new methods led to the production of sized materials such as paper, which were intended for one-time use. Later, this method was improved and led to the creation of the production of cushioning sewing materials for technical purposes.

Every year the production of non-woven fabrics is becoming more and more developed. This is explained by the possibility of using both various fibrous raw materials and production waste. Such replacement of fabrics with non-fabric materials gives a great economic effect due to the use of cheaper and less scarce raw materials, including fibers that are unsuitable for spinning.

An additional argument for the development of the production of nonwoven materials is the fact that the equipment used has greater productivity with less need for production space and a significant reduction in labor costs (5...7 times compared to labor costs in the production of fabrics) and less need for capital investments. The production of cushioning materials using the adhesive method can be carried out using one universal unit.

Labor productivity with the knitting-stitching method increases compared to labor productivity with the weaving method by 13...15 times, and with the adhesive method - up to 60...70 times. As a result, the cost of producing nonwoven materials is significantly lower than the cost of producing fabrics, which is especially important for the production of cheap children's clothing and clothing for one or two seasons. For example, the cost of knitting and stitching nonwoven materials is 1.25...1.38 times less than fabrics and knitwear, and adhesive edging is 4...5 times lower than linen woven edging.

The predominant growth in the production of nonwoven materials falls on materials for technical purposes (about 86% of the total output), but in recent decades the production of nonwoven materials for household use has also been growing.

Nonwoven materials for household use are already successfully replacing many types of fabrics: cushioning, clothing, towels, bed linen fabrics, etc.

For the manufacture of clothing, mainly canvas-, thread- and fabric-stitched non-woven fabrics such as fabrics are used, and canvas-stitched and needle-punched battings are used as insulating materials. Glued non-woven fabrics are used for gaskets that impart rigidity to individual parts of clothing and ensure shape retention. In addition to those mentioned above, nonwoven materials produced by felting and combined methods are widely used.

TECHNOLOGY FOR PRODUCTION OF NONWOVEN MATERIALS

The technological process for manufacturing nonwoven fabrics, regardless of the production method, consists of three stages:

- forming a base from a fibrous canvas or a frame from threads

- fastening the base or frame

– finishing of non-woven fabrics

The largest number of nonwoven materials are produced from fibrous canvas. The arrangement of fibers in the canvas can be oriented or chaotic. Canvases with an oriented arrangement of fibers are formed by overlapping canvases obtained from carding machines on top of each other. Canvases with a chaotic arrangement of short fibers are produced by aerodynamic or electrical formation. Canvases with a non-oriented arrangement of long elementary fibers are produced by the spunbond formation method, in which the fibers emerging from the dies during their production are immediately placed into the canvas.

In the clothing industry, the materials most widely used are adhesive and knitting-stitching methods.

When forming a fibrous web

They use fibrous mass from various types of fibers: natural (cotton, wool, flax) and chemical (viscose, nitrone, chlorine, nylon, etc.) in various combinations. Low grade non-spun fibers can also be used. The fibers are selected, loosened, mixed, and cleaned. Then, by carding, a fibrous canvas is formed.

Formation of the canvas can be carried out in several ways: mechanical, aerodynamic, electrostatic, hydrodynamic, etc. With the mechanical method, a fibrous canvas of the required width and thickness is obtained by placing several layers of combed fleece on a special grid. With the aerodynamic method, the fibrous mass is supplied by a stream of air to a special mesh drum, in which the canvas is formed under the action of air suction. With the electrostatic method, the formation of a fibrous web is carried out due to the movement and deposition of the fibrous mass in an electric field. The hydrodynamic method is based on the dispersion of fibers in a liquid and subsequent deposition and placement of them on mesh transport belts.

In addition to fibrous canvases, a frame made of threads is used for the base. It is a layer of roving or threads (yarns) laid parallel to each other or in the form of a grid. Low-density fabrics, non-woven fabrics, knitwear, synthetic mesh, and film materials can be used as a frame. These materials can be combined with fiber canvas or with layers of threads.

Bonding the base

carried out in various ways: knitting-stitching, needle-punching, adhesive.

The knitting-stitching method consists of knitting with threads (yarn) a fibrous canvas (canvas-stitched materials), a frame made of threads (thread-stitched materials), fabric (fabric-stitched materials). This method is called knitting-stitching because it includes elements of sewing and knitting. The element of sewing is the piercing of a fibrous canvas or layer of stretched threads. The knitting element is the use of knitting needles and the formation of a knitted weave.

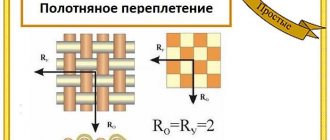

For knitting, single or twisted cotton yarn, nylon, chlorine, and lavsan complex threads are used. The base of the non-woven fabric is knitted with warp weaves: simple (chain, tights, cloth) and combined (tricot-chain, cloth-chain, etc.). On the front side of the knitting-stitching fabric there are loop columns, on the back side there are zigzag broaches. The base of the non-woven fabric appears as if inside a sparse warp-knitted fabric.

Canvas-stitched non-woven fabrics

are obtained in the production of fibrous canvases on carding and knitting units (Fig. 1) of the AChV series (AChV-1, AChV-V, AChV-250-III, etc.), as well as on machines of the Malivatt and Arachne series. Canvas-stitched fabrics are quite thick materials with a loose structure. The canvas stitching method is the main method for producing nonwoven materials for clothing.

Rice. 1

The complex of devices of a carding-knitting unit consists of a hopper for fibrous raw materials, a carding machine, a card converter, a knitting-stitching machine and a unit control panel. Fibrous raw materials undergo preliminary loosening, scuffing, removal of impurities, and mixing. These operations are similar to the production of yarn. From the hopper, the fibers enter the carding machine of the unit.

Combed thin canvas (fleece) with a longitudinal, almost parallel, arrangement of fibers ensures high uniformity of the material, but with an even greater difference in strength in the longitudinal and transverse directions. For this reason, it goes through a card converter, due to which the fibers in it take on a parallel-transverse arrangement, the material changes the direction of movement and is laid in several layers so that a canvas with a transverse arrangement of fibers is obtained.

As a result of this operation, a canvas is obtained, which is stitched with single or twisted cotton yarn or nylon and other threads on a knitting and stitching machine. The knitting and stitching unit has a system of reed knitting needles mounted in one comb. Each needle receives a cotton or nylon thread from a bobbin, which is used for stitching. The operation of the carding and stitching machines of the unit is regulated by a photocell installed on the unit.

This machine's operating principle is similar to a warp knitting machine for knitting production. The stitching process creates a simple chain stitch or other types of knitted weaves (for example, tricot-chain or cloth-chain). The distance between longitudinal stitches depends on the class of the machine and the purpose of the material.

Before the stitching unit, the incoming canvas forms a so-called compensation loop. If the loop size exceeds the norm, the photocell turns off the carding machine and turns on the stitching machine. As the canvas is stitched, the size of the loop decreases, the carding machine is turned on again, and the whole cycle is repeated. At some enterprises, for the production of knitting and stitching materials, they use machines “Malimo”, “Maliwatt” and “Malipol”, made by German manufacturers, or “Arachne” made in the Czech Republic.

The Malivatt (Fig. 2) and Arachne machines are similar in principle to carding and knitting units. The Malimo machine also produces thread-stitched non-woven materials - fastening of threads laid in the transverse or longitudinal direction and their tensioned systems is carried out. Using the Malipol machine, low-density fabrics are knitted in such a way that freely hanging loops are formed on one or both sides of the resulting material. Nonwoven materials from Malipol machines resemble terry fabrics.

Rice. 2

The productivity of various unit systems is 25...180 m2/h or 20...80 linear m/h. For comparison: in the same time, a weaving loom produces approximately 5...10 m2/h of fabric).

Depending on the class of the stitching machine (the distance between the needles), the nature of the knitted weave, the stitch direction and the type of thread used for stitching, knitting and stitching materials have different appearance and properties.

Fabrics such as flannel and flannel are produced on 10 class machines. (location of stitches every 2.5 mm), such as felts, draperies - on 5 class machines. (stitches every 5 mm), such as batting - on 2.5 cl machines. (stitches every 10 mm). The stitching density can be different and range from 10...55 loops per 50 mm of stitch length. Consequently, the higher the class of the machine and the higher the stitching density, the more durable and shape-resistant the material is. Yarn consumption is 10...25% of the material weight.

Non-woven fabrics produced by the canvas-stitching method and intended for the manufacture of clothing are subjected to finishing in much the same way as fabrics (dying or printing, rolling, napping, cutting the pile, pressing, calendering), with the exception of the processes of singeing, desizing, bleaching and some others.

Cotton non-woven fabrics such as flannel and flannel are subjected to napping, dyeing, printing, finishing, calendering, and sometimes embossing.

Wool-blend non-woven fabrics such as cloth and drapes undergo rolling, washing, dyeing, napping, shearing, pressing, and decating.

Cotton and wool-blend batting are practically not subjected to finishing.

Non-woven fabrics such as flannel, flannel, cloth and drape can be successfully used for the manufacture of children's coats, suits and sportswear, as well as women's dresses, skirts, and hats.

Non-woven fabrics such as batting are used as cushioning insulating material. In addition to the usual non-woven batting, you can produce batting that is doubled with cotton or silk fabric, with foam rubber - such batting is used for the manufacture of workwear.

Some non-woven fabrics have good wear resistance, slightly inferior to fabrics, high elasticity and crease resistance, breathability and good heat-shielding properties, low shrinkage.

The surface density of the non-woven fabric can be 120...600 g/m2, width 140...180 mm, thickness 1...3.5 mm, strength in the longitudinal direction 70...120 daN per strip of material 50x100 mm, in the transverse direction 20...50 daN, elongation respectively 36...60 and 60...180%, shrinkage 7 and 4%.

Depending on the fibrous composition, thickness and frequency of stitching, the properties of non-woven fabrics will be different. Fabrics containing viscose, linen and cotton fibers have the best hygroscopic properties. Fabrics containing wool, nylon, and lavsan are characterized by good elastic properties and wrinkle resistance. Fabrics containing nylon and lavsan are highly resistant to abrasion.

When modeling and designing clothing made from non-woven fabrics, it is necessary to take into account the peculiarities of their properties. Taking into account the significant stretchability, rigidity and low drapability of these fabrics, clothes from them should be made with the simplest possible lines and shapes.

When cutting half-woolen non-woven fabrics, it is necessary to take into account the shrinkage along the width by the amount of residual deformations; when cutting, shrinkage along the length and shrinkage along the width, i.e. you need to increase the length and reduce the width of the patterns. Due to the fact that the amount of attraction is greater than the amount of shrinkage, the area of the patterns for cutting non-woven fabrics should be less than the area of the patterns for cutting cotton fabric (flannel) by approximately 4%. It is advisable to cut all parts only in the longitudinal direction.

The production of garments from non-woven fabrics, due to the reduction in the number of technological treatments compared to their number when processing fabric products, requires 30...55% less time, which reduces the cost of products.

When making connecting and stitching seams, it is recommended to use cotton threads No. 40, 50, lavsan threads 33L and 55L, needles No. 90...110. The stitching frequency should be 4...6 stitches per 1 cm. For finishing seams, silk threads No. 33 and lavsan threads 33L can be used.

The WTO of products made from non-woven fabrics should be the same as for products made from fabrics, taking into account the structure of these materials and the fibrous composition. Humidification should be small (10...15%) and uniform, preferably using a moistened flannel-type iron. The iron pressure is quite low - (1...3)x104 Pa, temperature - 140...160 °C. Processing time on a press is 10...15 s, and with an iron – up to 25 s.

The range of clothing stitched non-woven fabrics is quite diverse and is updated annually with new types of fabrics.

Thread-stitched non-woven fabrics

obtained by knitting threads on a Malimo machine (GDR). They consist of three systems of threads: longitudinal, transverse and fastening. Two systems of warp and weft threads, superimposed on one another, are fastened with a third system using a chain stitch seam.

Finishing of non-woven fabric from Malimo machines (Fig. 3) is carried out using an abbreviated technology: bleaching, napping, printing, finishing, spreading, calendering. The result is a durable non-woven material, similar in properties to fabrics, but with a more voluminous structure and better heat-shielding properties than fabrics for the same purpose.

Rice. 3

The stable structure of the fabrics from Malimo machines provides good conditions for their laying and cutting. Slight fraying and stretchability of parts' sections make it possible to obtain high-quality garments. When modeling and designing products from these fabrics, the thickness of the material should be taken into account; the models should also be simple, with a minimum number of structural and decorative stitches. The dimensional stability of these products is good. The hygienic properties of linens are better than those of cotton paper: low thermal conductivity, good hygroscopic properties and breathability inherent in them are especially important for linen and children's products.

These fabrics can be produced from colored yarn with the formation of colored stripes and cells. The presence of three thread systems allows you to obtain fabrics stitched with various weaves and with a variety of color patterns. Threads of various structures (twisted, shaped, textured, different linear densities) and various colors (dyed, melange, mulined) are used.

Types of new fabrics have been created that imitate warp knitwear. They are recommended for making blouses and shirts, and thicker ones for dresses and suits. Coats, raincoats, bathrobes, and a variety of children's clothing can also be made from such fabrics. Among the latest developments, we can note lightweight fabrics for blouses (canvas “Emerald”) made from belan threads, bulky acetate thread stitched with lavsan thread; surface density is 114 g/m2.

Fabric stitched nonwoven fabrics

consist of a lightweight frame stitched with a system of pile threads in such a way that a looped pile is formed on the surface of the frame on one or both sides. For this purpose, “Malipol” (GDR) or “Liropol” devices are used. Fabrics, knitted fabrics, Malimo fabrics, film materials, and a pre-prepared fibrous layer are used as a frame.

Using needles, the frame is stitched, which is why pile loops are located on one side of the frame; on the other side, the pile thread is secured with a tricot weave, which gives the fabrics the appearance of a double-faced jersey. For stitching, twisted wool blend yarn is used. In a similar way, durable fabrics with a stable structure such as terry, plush, and faux fur are obtained. These fabrics are used in the production of bathrobes, swimsuits, jackets and coats.

Needle-punched method

is currently undergoing great development. It is used for bonding fibrous canvases and canvases backed with sparse fabric. Prepared fibrous canvases are pierced on needle-punching machines on one or both sides with special needles with notches, fixed in a needle bar that moves perpendicular to the plane of the canvas. Passing through the canvas, barbed needles grab some of the fibers and pull them through the entire thickness of the canvas, thus fastening its layers and stitching.

The size and shape of the needles depend on the type of fibrous raw material, the thickness and purpose of the canvas. The needles are rigidly attached to a special tile, which makes up to 900 beats per minute. The width of needle-punched materials can reach 7...8 m. For better bonding of fibers in the canvas, it is possible to add adhesives by introducing synthetic fibers into the mixture, which during heat treatment shrink and bind the fibrous canvas. Abroad, a water-jet method has been developed based on the principle of the needle-punched method.

The productivity of needle punching machines is 250…300 linear m/h. The canvas is then passed through a hot water bath, where the synthetic fibers shrink and the canvas is densified, thereby increasing the material's strength and resistance to delamination.

If the layer contains thermoplastic fibers, then when pierced with hot needles, the fibers in contact with them melt and bond together, which increases the strength of the material.

To increase the strength and reduce the extensibility of the nonwoven material, a fibrous layer is applied to both sides of the thin fabric and connected by needle puncture.

Similar fabrics (such as cloth) are used for the manufacture of outerwear, blankets, rugs and for technical purposes (production of insulating gaskets). They have satisfactory physical and mechanical properties, good appearance and are characterized by great efficiency. The Central Research Institute of Wool has developed a technology for manufacturing needle-punched fabric for lower collars, the purpose of which is to ensure the dimensional stability of the collars of men's suits. The cost of the canvas is 3 times lower than that of felted canvas.

Glue method

production of nonwoven materials (Fig. 4) is distinguished by the fact that it almost completely eliminates the labor-intensive processes of spinning and weaving. The method involves gluing fibers and threads using polymer substances.

Rice. 4

The bases of non-woven fabrics of various types are held together using the adhesive method: canvas, a system of threads, combinations of canvas with threads, fabric, etc. Two gluing options are used: wet (by impregnating the fibers with liquid substances) and dry (gluing with thermoplastic substances). A method for gluing fibers with binders introduced into a fiber suspension has also been developed.

When wet gluing, liquid binders are introduced into the prepared canvas in the form of solutions, dispersions, polymer emulsions, and latexes. The canvas from a carding machine or obtained by an aerodynamic method passes through an impregnation machine to apply a liquid binder, then through a drying chamber, where the non-woven fabric is dried or heat-treated depending on the type of binder, after which the material enters the calenders. In this way, cushioning materials are produced.

For dry (thermoplastic) gluing, thermoplastic (low-melting) staple fibers, meshes, threads, films, powders, etc. are used, which have a lower melting point than the bulk of the canvas; With appropriate heat treatment, thermoplastic substances soften and glue the base of the non-woven fabric.

Binders can be added in different ways:

— a certain percentage of low-melting fibers (nylon, anide, etc.) can be added to the composition of the fibrous canvas.

— adhesive threads, films or meshes made of thermoplastic materials can be laid between layers of combed fibers

— adhesive thermoplastic powder can be sucked through the thickness of the fibrous canvas. During subsequent heat treatment, thermoplastic substances melt and bind the fibrous web.

The most common adhesive method for fastening fibers in canvas is continuous impregnation in a bath with liquid binders. According to this method, the fibrous layer is passed through a bath containing an adhesive substance (solutions, emulsions, latexes), then squeezed out, dried, calendered and heat-fixed at a temperature of 120...130 °C for 10...15 minutes. Aqueous emulsions of synthetic products (SKR-40-1GN latex, L-4 latex, polyvinyl acetate dispersion) are also used as binders. By gluing canvas fibers with latex, cushioning sewing materials are produced - non-woven fabric, proclamelin, "Syunt".

Non-woven laminated fabrics are produced on ANM-110, ANK-110 units with a productivity of up to 600 linear m/h. These machines at one time played a major role in the development of the production of glued nonwoven materials. Fibrous raw materials enter the unit in the form of a heterogeneous canvas obtained on a loosening-scraping unit. First, the canvas is combed and then fed into an aerodynamic canvas-forming machine, in which an air flow on a mesh surface forms a canvas of uniform thickness with a non-oriented arrangement of fibers. A material of this structure has uniform strength in all directions.

Depending on the purpose, non-woven laminated fabric can be produced in a raw form (edging, volumetric thermal insulation fabric) or dyed, printed (decorative and clothing material).

Non-woven glued fabrics have a variety of surface densities (30...300 g/m2) and thickness (0.25...1.0 mm). Depending on the fibrous composition, their properties may be different. Cotton fabrics are soft and elastic, but not strong enough. Adding nylon fibers to the mixture increases the elasticity and strength of the fabric. Thus, using certain fibers in a mixture, it is possible to obtain a fabric with the desired, predetermined properties.

Currently, the range of glued nonwoven materials has expanded significantly, new integrated production lines for processing raw materials have been created (Fig. 5) with aerodynamic web-forming machines, machines for laying longitudinal threads, impregnating machines, cutting-rolling machines, etc. On these lines, it is possible to produce nonwoven materials with different arrangements of fibers in the canvas by applying binders by plusing, impregnating the canvas in a bath in a suspended state, applying foaming agents or a dry binder polymer in powder form by pumping through the canvas, embossing with figured shafts or threads along the canvas.

Rice. 5

Several decades ago, a dry method of gluing a mass of fibers with thermoplastic substances was developed and widely used. Low-melting fibers or powder are introduced into the formed fleece, which melt during hot pressing, gluing the surrounding fibers. It is possible to obtain non-woven material from comb fleece, consisting entirely of hot-melt fibers (lavsan, nylon, etc.). In this case, hot pressing should be done in separate areas (spot welding) to avoid the fleece turning into a continuous film.

Such nonwoven materials are produced on the ANT-100 unit. The productivity of the method is 1.5...2 times higher than the productivity of gluing fibers with liquid binders.

Nonwoven materials obtained by gluing with thermoplastic substances can be used for both technical and household purposes as cushioning material or material for outerwear.

In recent years, a promising high-performance method has been developed for producing nonwoven materials for lining in clothing and other purposes from a polycaproamide melt with aerodynamic drawing of complex threads and their simultaneous formation into canvas in a vertical plane. The productivity of the equipment is 3...30 times greater than when producing nonwoven material on knitting and stitching machines. Surface density of the material is 76±5 g/m2, thickness 0.6 mm, width 110...120 cm.

Nonwoven materials consisting of thermoplastic fibers can be joined not only with threads, but also with high-frequency currents using special devices MST-3M, LGSP-04, etc.

In foreign practice, the method of gluing fibers with binders introduced into a suspension of fibers, the so-called paper-making method, is becoming widespread. Nonwoven materials using this method are produced on paper industry equipment. This method is 30 times more productive than the method of gluing fibers with liquid binders.

When producing nonwovens using this method, the binder is released directly into the fiber suspension. Low-melting fibers (fibrids) or polymer solutions can be used as a binder. The production cycle consists of the following main operations:

- preparation of fiber suspension

- introduction of a binder

- formation of web on the mesh of a paper machine

- dehydration

- drying

- hot pressing

Nonwoven materials made using fibrids are called textiles

. Women's dresses, men's shirts, bed and underwear, towels, tablecloths, and disposable napkins are made from such materials. The first textile material called “bunelan” was produced in Russia, used as a basis for artificial leather used in the production of hats.

Glued non-woven fabrics in the form of voluminous cushioning materials are used as insulation in clothing.

The basis of the felting method

The production of nonwoven materials relies on the ability of fibers to felt, for example, woolen fibers under the influence of mechanical forces in the presence of heat and moisture, cotton fibers under the influence of various chemical reagents. The technology for producing fabrics using the felting method is based on bonding fibers together during the felting process, which makes it possible to obtain pure wool or half-woolen materials such as cloth and drape.

For the manufacture of materials, fine wool fibers with the addition of polyamide fibers are usually used. To increase the strength of materials, before the felting process, threads can be laid in the transverse direction between two layers of combed fibers using a special machine. Due to the need to use expensive raw materials, the fulling method has not become widespread.

The roller method produces felt non-woven material (Fig. 6), which is used as a lining under the collar of men's suits instead of suit fabric, which brings a significant economic effect. The fiber composition of this material: 70% wool and 30% viscose staple fiber, width 145 cm, surface density 210 g/m2.

Rice. 6

In addition to the described methods for the production of non-woven fabrics, other combined methods

their production, which are various combinations of the methods discussed above, for example, knitting and stitching with glue, needle punching with glue. In this way, nonwoven materials are produced onto the fabric for lower collars.

Finishing of non-woven fabrics

similar to fabric finishing. When finishing, the increased extensibility of non-woven fabrics is taken into account: all finishing operations are carried out with minimal tension on the fabric. By analogy with fabrics, non-woven materials used for the manufacture of clothing are produced bleached, plain-dyed, variegated, and with printed patterns. Cotton fabrics are boiled and bleached. Wool-blend fabrics are rolled or brushed. Nonwoven fabrics are brushed, permanently embossed, and subjected to final finishing.

QUESTIONS FOR PREPARATION

- What are nonwovens?

- What can be included in the base of non-woven fabric?

- How is the structure of non-woven fabrics bonded?

- What explains the rapid development of nonwoven materials production?

- What is the technological process for producing nonwoven fabrics?

- What is the raw material for the production of non-woven fabrics?

- In what ways is the canvas formed? Give a detailed answer.

- Explain with examples how to fasten the base of non-woven fabrics.

- Describe canvas-stitched nonwoven fabrics and methods for their production.

- Name the components of a carding and knitting unit.

- Describe the process of obtaining canvas-stitched fabrics.

- What machines are used to produce quilted canvas?

- Compare the productivity of weaving looms and canvas stitching machines.

- What finishing operations do canvas-stitched materials undergo?

- What are the properties of various canvas stitching materials? Give examples.

- What is the structure of thread-stitched fabrics?

- What finishing operations are applicable to thread-stitched fabrics?

- Name the characteristic properties of thread-stitched fabrics.

- Give characteristics of woven-stitched nonwoven fabrics.

- Describe the manufacturing technology and characteristics of needle-punched fabrics.

- What is special about the adhesive method for producing nonwoven fabrics?

- Describe the types of technological production of adhesive nonwoven fabrics.

- How are binders added to adhesive sheets?

- Describe the sequence of operations for manufacturing adhesive sheets.

- Name the areas of application of adhesive non-woven fabrics.

- What new methods for producing adhesive sheets do you know?

- What is the technology of the fulling method for producing nonwoven materials?

- Name the main types of finishing of non-woven fabrics.

Features of needle-punched materials

Needlepunched nonwovens are felted and highly flexible, with a fibrous mesh structure making them suitable for filtration applications. Polymer fibers become entangled, forming a complex three-dimensional structure with random weaves. The shape and number of spaces between the fibers depend on the number of needles in the needle board, their size, advancement per stroke, piercing density and type of fiber.

Fabric density can be controlled by needle punching parameters such as density and needle penetration depth; Non-woven needle-punched fabric is made from multilayer structures to achieve the required filtration efficiency, compactness, non-extensibility and mechanical strength.

The surface finishing of needle-punched materials includes felting, calendering and glaze singeing, and the protective finishing includes antistatic, anti-adhesive and anti-abrasive finishing, fire resistance, chemical resistance, water-repellent coating. In this way their ability to filter is increased.

Needle punched filters have a wide range of fabric properties from 50 g/m2 to more than 1000 g/m2; their thickness ranges from 0.5 mm to 10 mm, depending on the application. They are used in industries including air filtration, water filtration.

Advantages of needle-punched materials:

- High strength;

- Virtually indeformable and non-stretchable;

- Heat resistant;

- They do not allow moisture and large dust particles to pass through, so they can be used as a filter layer;

- Frost resistance.