Do you think that padding polyester filler is not suitable for long-term service? Read below why you should choose it and how to determine its quality.

Sintepon as a filler

It is important to know how to care for products with synthetic filler in order to extend their service life. In this article we have collected all types of synthetic fluff and recommendations for caring for it.

Sintepon is often used as a filler for various products. The advantages of the filler are its relatively low cost and practicality. The production of this material is available everywhere.

Let's consider the main characteristics and points that it is advisable to pay attention to when purchasing products with padding polyester filling.

Insulation with a density of 150–250 g/m² - what kind of weather can an adult wear?

Everyone is familiar with the situation when in spring or autumn it is frosty in the morning, but warm in the afternoon and you don’t know how to dress. When buying warm clothes, you should check with the seller what the density of the filler is. The recommended density for the second half of autumn, when frosts begin and the temperature drops to -5 degrees Celsius, is 150 g/m². In winter frosts down to -20 °C, the optimal option would be a padding polyester density of 250 g/m². The data is relevant for adults, children do not have such a high heat transfer, but they are more active, overweight people freeze less than thin people.

Composition and production

A soft and white material made of thin fibers, similar to cotton wool - this is what padding polyester looks like. It contains thin polyester threads, sometimes with the addition of cotton or wool - they are used to increase the strength and heat resistance of the product.

PVA is often used in production to strengthen the fibers. There are several ways to produce padding polyester, which gives the material certain characteristics. Price differences start from the manufacturing method. Here are the most common:

- Thermal. This method makes it possible to produce a lightweight and durable material by bonding the fibers using high temperatures. The resulting padding polyester protects well from the cold and is not subject to deformation when washed.

- Needle-punched. With the help of metal jagged needles, the fibers are fastened together, forming a lush and soft padding polyester. With this method, the filler is not resistant to deformation.

- Emulsion. A special adhesive composition and synthetic threads are what padding polyester is made from. The material as a result of such processing may cause allergic reactions. It is not resistant to deformation, and with frequent use it quickly rolls off.

Oeko-Tex certification

Particular attention should be paid to the environmental friendliness and safety of the material for the human body. In 1992, an international system for testing and certifying products for the absence of harmful chemicals was developed - Oeko-Tex Standard 100.

Responsibility for certification is shared by 17 research institutes united by the Oeko-Tex organization. It is based on the study of the material for compliance with the pH value, the presence of formaldehydes (hazardous gases) and heavy metals, as well as allergenic dyes.

The Oeko-Tex Standard 100 certificate is one of the most prestigious today.

Its presence indicates the complete safety of the insulation for the human body. All manufacturers of synthetic insulation discussed in this article have an Oeko-Tex Standard 100 certificate, with the exception of synthetic winterizer, since it is not a trademark and can be produced by different companies.

Main characteristics

- Ease. The weight of the padding polyester product is small.

- Non-absorbency and quick drying. This can be both a plus and a minus when using it.

- Low deformation under normal use. Sintepon holds its shape well and slowly deforms.

- Non-toxic. Synthetic padding polyester created without glue is absolutely safe. Often used for children's products.

- Low melting point. There is a possibility of accidentally melting the “filling” of your favorite pillow. For this reason, it should be kept away from open flames.

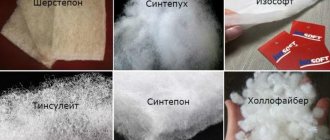

Types of padding polyester

Different types of this material are used for specific purposes. Their main difference is in the additives they add to each other - additives made from natural or synthetic materials.

- Shersepon. Sintepon with the addition of natural wool - used to create products with increased heat resistance. Used in blankets and bedspreads.

- Sinteplast. Non-woven voluminous fabric with the addition of silicone to increase elasticity. Suitable for mattresses, children's rugs and furniture; thanks to silicone, the shape is firmly held and the filler does not roll off.

- Holofiber or padding polyester. Highly crimped fiber with high silicone content on a polyester base. Produced in the form of a sheet or individual balls. Acts as a filler for decorative pillows.

How is thermofiber made?

Petroleum derivatives of polyethylene terephthalate and its derivatives are used as the starting material. During production, microfibers are soldered together under the influence of strong heat treatment. The technology differs from the manufacture of padding polyester in that no toxic products are produced during production and no glue is used. Although in favor of modern padding polyesters it can be noted that they have become completely different than they were 15-20 years ago, and their consumer properties are not much inferior to holofiber.

During the manufacturing process, the fibers pass through a carding machine and are immersed in a hot oven, where under the influence of high temperature they are combined and turned into a large canvas.

The web then passes to the winding unit, where it acquires the correct degree of shrinkage and thickness.

Advantages and disadvantages

Advantages of padding polyester:

- Cheaper than natural materials.

- Elasticity of fibers. Thanks to this, the canvas is less susceptible to deformation.

- Wide variations of application both in creativity and in production.

- Large volume in relation to mass.

Disadvantages of padding polyester:

- When rubbed, it creates static electricity.

- Destruction of fibers due to frequent machine washing and improper drying.

- May cause allergies (created by emulsion method or with the addition of PVA).

Application area

What is padding polyester for the manufacturer? The material is universal, easily accessible and inexpensive, therefore it is used for:

- production of upholstered furniture;

- in outerwear to create an insulating layer;

- filling bedding, soft toys, decorative elements;

- filtration;

- construction work, as insulating material;

Synthetic winterizer with natural additives is used less often. Material with wool threads is used for blankets, pillows and bedspreads. Sintepon with added cotton is suitable for decorative items.

Fabric with silicone is of very high quality, since this additive in the composition makes the product more durable; it is used in mattresses, blankets and expensive furniture.

A little theory

The amount of thermal energy generated by a person depends on the person’s individual characteristics, well-being, and even on how well he ate and slept. The role of clothing with insulation is to preserve this same energy.

Thermal insulation is the process of reducing heat transfer between the body and the environment. It is not for nothing that insulation in English is always defined by the word Insulation - insulation.

A vacuum environment has minimal thermal conductivity, and the most accessible heat insulator with low thermal conductivity is dry air. It is dry, since moisture is a good conductor. The more air molecules the insulation holds in one cubic centimeter, the better its thermal insulation properties.

Air is always in motion - warm air tends to rise, cold air goes down; this factor must also be taken into account when developing insulated clothing.

Thus, the main task of clothing insulation is to keep the air warmed by our body inside, and not let the cold air outside.

Important quantities that allow us to describe the qualities of insulation:

R-value

– the value of the thermal resistance of the insulating layer. Reported in CLO. The higher the R-value, the better the thermal insulation properties of the material.

Fill Power (FP)

– the most common indicator of the quality of insulation (usually natural down).

This characteristic shows the ability of the insulation to recover after compression. The higher the FP index, the warmer the product for the same weight of down. Some companies working on the European and American markets sometimes indicate the double value FP-750 FP Euro, 850 FP USA. This is due to the fact that quality standards in these zones are slightly different. By the way, all synthetic analogues have characteristics similar to FP600 fluff. One of the most important characteristics of insulation is the value of thermal resistance per unit weight of insulation

.

This indicator determines how heavy the insulated jacket for specific temperature conditions. Durability

is an essential characteristic, especially considering the considerable price tag for high-quality insulated clothing.

For example, cheap insulation materials can fall off and cake over time, changing their density, which leads to a decrease in thermal insulation properties. Perhaps someone noticed that after washing, some insulated products retained heat an order of magnitude weaker. Hydrophobicity

(describes the interaction of a material with water).

Synthetic insulation, as a rule, is not hygroscopic, i.e. do not retain moisture. The same cannot be said about fluff. For insulation to be as versatile and effective as possible, it must retain heat in humid conditions. Compression ability

.

One of the most important tasks for outdoor workers who are assembling a backpack is to choose equipment that is as light and compact as possible. The most important advantage of down products is their minimal volume when folded. Modern synthetic insulation may be inferior to down in terms of compression, but they are definitely close to it. Often a vest or jacket can be folded into its own pocket.

Elasticity

.

In relation to insulation materials, this is the ability to restore the original structure, actually volume. The structure of synthetic fibers is most often restored faster than down . This is partly why down jackets often have inserts with synthetic insulation in the shoulder area and on the sides of the jacket , where the greatest pressure is exerted.

But, despite technical progress, down remains the best insulation . Most often, goose down - it is more durable than duck down, and also cheaper than down . Highly purified goose down Fill Power and is optimal in terms of price-quality ratio.

Sintepon in outerwear

Layers of padding polyester exist in different densities from 60 to 400 g/sq.m. The main difference is in heat conservation. The higher the density of the material, the greater heat efficiency it has

It is important to choose outerwear depending on the temperature at the time of wear. Don't forget that children are more active than adults and their clothes should be thinner.

Synthetic winterizer 100 g/m² is intended for thin coats and jackets for warm autumn with temperature fluctuations up to +5°C. Synthetic winterizer 150 g/m² is well suited for frosts down to -5°C. A coat or down jacket with padding polyester 200 g/m² can be safely worn in late autumn and warm winters down to -10°C. Synthetic winterizer 250 g/m² is suitable for winter -20°C. Material with a density of over 250 g/m² is used in down jackets for frost temperatures of -40°C and above.

When buying outerwear, check the density of padding polyester insulation and calculate based on your individual build. The higher the physical activity, the less you will freeze, so you should take a lower density.

Variety of insulation materials

The modern market of outerwear for children and adults offers the following insulation materials:

- holophane;

- padding polyester;

- holofiber;

- down and feather;

- fleece;

- artificial fur;

- natural fur;

- isosoft;

- Thinsulate.

Not all of them are common, but the most popular among them are padding polyester, holofiber, and sheepskin.

Caring for products made from padding polyester

When washing clothes with padding polyester, follow the instructions on the tag or in the instructions. If they are not available, we use a temperature regime no higher than 40°C and additional drying in a washing machine so that the synthetic winterizer does not lose its shape. Dry clothes strictly in a horizontal position to avoid redistribution of threads. If the material is made of adhesive synthetic padding, we use only hand washing, otherwise filler. Items filled with thermal and needle-punched synthetic padding can be machine washed.

It is advisable to clean clothes and decorative items no more than once a month, and remove minor stains with wet wipes.