Home / Blended fabrics

Back

Published: 12/19/2020

Reading time: 2 min

0

444

Fans of natural materials know exactly what a cooler is. This is a 100% cotton material that stretches well in width, but does not stretch at all in length. A cooler with lycra does not have this drawback. The fabric remains natural and only gets better thanks to the addition of lycra. Things stretch well and take the desired shape.

- 1 Description

- 2 Composition and manufacture

- 3 Features of FullyCra

- 4 Types depending on quality

- 5 Advantages and disadvantages

- 6 What are they sewing from lycra?

- 7 Care

- 8 Reviews

- 9 Conclusion

Description

Fullycra fabric is the optimal combination of cotton and lycra (elastane). Fabric that stretches perfectly in all directions. The optimal amount of elastane in the fabric makes the material 30% stronger.

Lycra - allows air to pass through well and does not impair the quality characteristics of the base threads. Elastane is washable. In the finished product, the cooler and lycra are optimally combined, it becomes elastic, retains its shape, fits the figure, and does not restrict movement. The color does not lose its brightness after many washes, the item does not stretch, and remains hypoallergenic. You can apply prints, silk-screen printing, or use thermal printing technology on the canvas.

Mixed

The most popular fabrics on the market right now are mixed fabrics. Nowadays, it is rare to find any item that is entirely composed of the same fibers. The combination of several types of threads from different groups (for example, natural and synthetic) helps to create new materials that have unique properties and can also boast greater strength and durability.

Acrylic woolAngelicaSatin-stretchTarpaulinViscose + polyesterViscose + polyester + elastaneViscose + polyester + elastaneViscose + elastaneViscose and spandexLuxury corduroyGabardine melangeGabardine stretchGuipure and laceTapestryGretaDivingDiving on fleeceDiorIntersoftCanvasKirzaCotton-memoryCre p-divingCrepe-stretchCrystalCrystallonKristinaKulik with lycraCorduraLameMadonnaManchesterOilMemoryMicrovelourMicrodivingMicrooilMilanoNicoleOttoPanamaBrarchRaincoatPleecePolyviscosePolycottonPolysatinRelaxRip stopSatoriSoftcottonStretchTaktelTwillTiarTick TisiUltraso ftUltrastepFlockFooter with LycraCotton with acrylicCotton with viscoseCotton with modalCotton with polyamideCotton with polyesterCotton with elastaneCotton with spandexStretch cottonChenilleStapleEco leather

Composition and manufacture

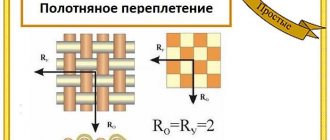

Knitted stitch with lycra is classified as a simple weave, which is also called stockinette stitch. The result is a double-sided fabric, with internal loops or “brickwork” on the inside, and front loops or “braids” on the outside. The surface has a heterogeneous structure and curl. To create the fabric, use 1 thread.

You can create a knitted stitch using hand or machine knitting. On an industrial scale, circular knitting or circular hosiery machines are used. Lycra is added in the amount of 5% to 30%.

Fact! Lycra is also called elastane or spandex. This is an elastic fiber that, when added to another thread, makes the fabric stretch without tearing. The more elastane, the more stretch the fabric will have.

According to the method of staining, they are distinguished:

- melange, that is, before knitting the fabric, the fibers are dyed, twisted and only then knitted;

- plain-dyed, that is, the canvas is painted after it is created;

- The printed pattern is produced by applying it using a special printing press.

A pattern with several colors is obtained in 2 ways: by dyeing the finished canvas; using threads of different colors.

History of origin

The technology for creating a kulir fabric is quite ancient, it is almost five hundred years old. In the old days, the material was woven by hand until William Leigh invented the prototype flat knitting machine in 1589. The inventor used curved needles and a wooden beam to facilitate the difficult work of his bride, and this became the basis for the creation of subsequent models of machines.

Nowadays, all types of knitwear are produced automatically. Plants and factories install programmable equipment and use various systems to create different types of weaving fabric. With the addition of lycra, this type of cotton material began to be made only in the second half of the 20th century. Initially, the creation technology was quite complex, but as the popularity of stretchy, practical clothes grew, semi-automatic and automatic machines began to be created. Due to this, the cost of stretch cotton has decreased.

Features of FullyCra

The main feature and difference from an ordinary cooler is that lycra gives elasticity. Things made from full lycra not only stretch perfectly, but also take the desired shape, even after multiple washes. No creases or folds form on it.

This is a thin fabric, ideal for sewing summer clothes, as it contains at least 70% cotton fiber. Therefore, wardrobe items made from full lycra are hygroscopic, absorb moisture, are comfortable to wear, and pleasant to the touch when in contact with the body.

Types depending on quality

According to the type of cotton fabric used and, accordingly, the quality, full lycra is classified:

| Name/labeling | Characteristics | What are they sewing? |

| O/E Open End | Fibers with a length of 20 to 30 mm are used. The fabric has a low density, after several washes it stretches strongly and rolls up | For sewing soft toys |

| Card or ring | Fibers of medium length from 25 to 35 mm are used for production, have average consumer qualities, and have a characteristic “fluff” on the surface. | For tailoring |

| Peña | To make the fabric, fibers with a length of 30 to 70 mm are used, due to which it is strong, has no lint, does not pill, and does not lose its shape. | Almost any wardrobe and household items |

A cooler with premium or compact lycra foam additionally undergoes a special processing stage, due to which all existing defects that are inherent in other types of cooler are eliminated. It is smooth, silky, and wear-resistant among all types. It practically does not wrinkle, and only the highest quality cotton was used in the production process.

Depending on the type of waistband and the amount of elastane, the density of the finished fabric varies. The optimal indicator is considered to be 180-220 g/m2.

Author:

Anastasia Kukushkina

I hope you enjoy the article I have prepared for you! If you find errors in it, write to me about it! I will answer any questions you have, ask them!