What is acrylic: Pixabay What is acrylic? Acrylics include fabrics, paints, and plastics. The question arises as to how the same material can be used in knitting threads and plastic structures. To figure it out, ask what kind of material acrylic is and what properties have made it so widespread in industry and everyday life.

What is acrylic fabric

In the collection of modern synthetic fabrics, acrylic fabrics take pride of place. The name “acrylic” is translated as synthetic acrylic resin.

Despite its artificial origin, fabric made from acrylic fibers is soft and light. Very reminiscent of natural wool. Apparently, this is why it is often called “artificial wool.” This is due not only to external similarity. According to some characteristics, acrylic fiber is superior to wool yarn. It is more durable, smoother, and the fabric made from it has a clearer pattern.

Acrylic stone concept

In general, the production of acrylic stone is quite labor-intensive and complex. First of all, this is due to the fact that it is impossible without the use of specialized equipment. This material consists of almost 80% natural raw materials, which are most often marble chips. Everything else is acrylic resin, the main polymer filler. It should be noted that since this substance is a binder, the quality of the final product largely depends on it. In this regard, it is not recommended to save on filler.

History of origin

In the middle of the last century, the DuPont company (USA) was actively working to create a new material that could compete in quality and properties with nylon, which was popular at that time. The result of these studies was the appearance of synthetic fiber “Orlon”, isolated from polymers. The material turned out to be incredibly practical and in many respects was superior to many artificial and natural analogues at that time.

However, the new fabric had a significant drawback - the fibers were practically resistant to dyeing. Only in 1952, four years later, DuPont chemists were able to solve this problem. Essentially, they created a new version of a previously invented synthetic fabric that now met all the requirements. And most importantly, it was beautifully colored.

This date is considered the birth of acrylic fabric, which in subsequent years quickly spread in the textile world and surpassed nylon in many respects. In the USSR, the universal synthetic acrylic fabric was known as nitron fiber or nitron. We can say that from this moment began the era of artificial wool and trendy material, which has dominated the production of quality clothing throughout the world for the second century.

Methods for characterizing EGFR mutations

The first stage of the study is a biopsy. It is important that the study material contains enough cancer cells and is large in size.

To detect the changed EGFR gene, polymerase chain reaction (PCR) is often used. This method allows you to create multiple copies of DNA using enzymes.

Upon completion of the analysis, there can be 2 conclusions:

- A mutation in the EGFR gene has been detected, with its characteristics required;

- No mutation detected.

Taking this into account, the doctor determines which treatment tactics to choose.

What is acrylic made from?

The raw material for the production of synthetic fibers is natural gas, from which chemical compounds are obtained. With their help, acrylic fibers are synthesized.

The dominant material in this process is acrylonitrile, from which polyacrylonitrile is obtained by polymerization in the presence of catalysts. The share of acrylonitrile in the composition of raw materials for the production of synthetic fibers, according to international production standards, must be at least 85%.

The main component of acrylic fiber is a toxic substance in itself. However, the resulting acrylic synthetic fiber is safe for use. Because acrylonitrile, when combined with other elements during the synthesis process, quickly decomposes.

As a result of a series of chemical reactions, acrylic fiber is formed into a continuous thread from a solution of polyacrylonitrile resin. Due to the special structure of acrylic threads, the finished material is high-quality, smooth, with a clear weaving pattern; acrylic items, clothes, and textiles are made from it.

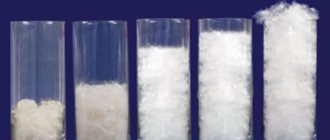

When producing various products, manufacturers use either a wet or dry method of spinning fibers.

Having received a synthetic solution in the form of a colorless liquid after synthesizing the raw materials, technologists send it into a container with air or water, rotating and squeezing it through special equipment. There, after some processing, the fiber hardens. Then it is washed, dried, and cut to the required length.

The dried threads are wound into balls, from which acrylic fabric is woven using various techniques: plain, knitted, jacquard, matting.

To give the material an original “woolen” structure, after processing the synthetic fiber is cut into staples - narrow strips of equal size. They are woven into threads that imitate natural wool. They are used to knit interior items and warm clothes for adults and children.

A special feature of acrylic fabric is its characteristic dyeing method. Paint is added to the raw material during its production process, rather than impregnating the finished canvas with coloring pigments, as is usually the case. This technology gives excellent results. Paints that do not fade for a long time penetrate deep into the structure of the canvas, saturating it with bright color.

Manufacturers produce acrylic fabrics in different colors. In terms of design, the canvas can be printed with geometric, floral prints, patterns or plain.

Most acrylic fiber is produced in China, the USA, Russia, and Spain.

Production of acrylic stone

For a material such as acrylic stone, the manufacturing technology is not complicated. Initially, the filler undergoes a series of laboratory analyzes and tests, after which, if there are no flaws, it is sent to the production workshop.

Next, all the components must be mixed so that the resulting substance becomes completely homogeneous. This is one of the most difficult stages of production. In order to obtain high-quality acrylic stone, you need to adhere to all proportions.

The next stage is the casting of sheets. Most modern manufacturers use vacuum processing of finished products. This production of acrylic allows, as a result, to prevent the porous structure of the material. The stone is more durable and less susceptible to contamination.

Acrylic composition

Acrylic fiber is based on a polymer – acrylonitrile. And although 100% synthetic fiber may well exist as an independent unit and be used, it is still almost never found in its pure form.

It usually contains artificial or natural fibers in one quantity or another. Manufacturers use viscose, cotton, wool, and polyester as such additives, which significantly improve the original properties of synthetic fabric.

- Viscose increases the elasticity of the material, giving it softness and silkiness.

- Polyester makes the fabric more durable and moisture resistant.

- Wool improves the appearance of the material and increases its performance properties.

- Cotton gives synthetic fabric the hygienic properties of natural material.

Proper drying

Acrylic items need to be dried carefully, as they can easily lose their shape. Under no circumstances should you dry it on a dryer or clothesline! The washed item is lightly wrung out, shaken lightly, and then laid out on a terry towel. The product is given the desired shape, the seams and collar are aligned. The item should remain in this form until completely dry.

Is acrylic a natural or synthetic material?

Having studied the composition of acrylic, you can clearly answer this question, which is often asked by buyers when encountering this fabric for the first time. According to the manufacturing method and the raw materials used, it is a synthetic material. And it was obtained artificially. However, this is not a reason to refuse acrylic fabric because it is made from petroleum products.

At all stages of production, synthetic fabric is tested for environmental safety and quality. The best guarantee that the material will not harm is the recommendation to use many types of it in the production of children's clothing. And the more natural fibers acrylic fabric contains, the safer the clothing.

Specifics of running this business

The main feature of this type of business activity is that it is unlikely that you will have to work directly with the customer. In the vast majority of cases, such services will be used by small furniture companies. They bear all responsibility for installation and delivery. On the other hand, usually this feature forces companies to set rather short deadlines for the production of the necessary elements. It is very important to ensure that acrylic for countertops is always in stock and that its delivery dates are not violated.

Properties of acrylic

The material is elastic, durable, wear-resistant.

Acrylic fabric is resistant to acids and alkalis, does not deform when washed, does not shrink, or fade. But with constant exposure to ultraviolet radiation, the structure can change: become rigid and dry out.

When burned, the fabric melts, producing black smoke with a sour odor characteristic of synthetic fabrics, and bakes into a solid lump. Based on these signs, you can understand that this is synthetic and not natural fiber.

The fabric is comfortable to wear and rarely causes allergies.

Benefits of producing acrylic countertops

Recently, the production of kitchen furniture using this material has been a fairly profitable type of business activity. The explanation for this is quite simple. The fact is that acrylic countertops in most cases are manufactured by third-party companies, since it is much more profitable for small furniture manufacturers to order them rather than invest in the necessary equipment.

In addition, a significant part of the time the equipment will stand idle, because there will not always be constant orders for this type of furniture. To organize a business, you need to obtain the status of a private entrepreneur.

Advantages and disadvantages

The list of disadvantages and advantages is compiled based on customer reviews and will complement the general understanding of this material.

Here's what most of them note as advantages:

- brightness of colors and shades, variety of colors and patterns;

- The material is soft in texture and pleasant to the touch;

- environmental Safety;

- hypoallergenic;

- good heat-saving properties and moisture resistance;

- easy care: the fabric wrinkles little and retains its shape well, is easy to wash, dries quickly, and does not shrink;

- Due to the elasticity, clothing made from acrylic is comfortable: nothing hinders movement;

- synthetic fabric is not damaged by moths;

- does not fade in the sun and does not fade when washed with powder;

- I'm attracted by the affordable price: things and acrylic yarn are always on sale.

It is worth mentioning the disadvantages:

- clothes made of acrylic become electrified and attract dust - using antistatic agents you can cope with this problem;

- in the heat, you can quickly sweat in such clothes, the fabric does not “breathe” well - the problem is solved if you use a material that, in addition to acrylic, contains at least 30% natural fibers;

- when worn for a long time, the fabric rolls up and pellets may appear on its surface - the clothes can be cleaned;

- oil and grease stains that get on clothes are absorbed instantly and are difficult to wash off;

- when dried, things become rigid and become even more electrified;

- not all types of acrylic fabric are suitable for children's clothing;

- Things can stretch and become deformed if not properly cared for.

Expert opinion

Natalya Kadatskikh

Designer, fabric expert with 20 years of experience

Acrylic clothing retains heat well and dries quickly after washing. These fabric properties are often used for sewing winter models. But acrylic fabric is by no means a rare guest in summer clothes. It is often used in the production of lightweight knitwear.

Functions of EGFR

One of the key words in the name EGFR is “receptor”. This is what they call nerve endings that allow you to feel something, for example, taste, warmth, etc.

If we talk about molecular biology, the receptor is localized on the cell surface, with one part of it outside and the other inside the cell, and contributes to the cell’s sensitivity to molecular signals.

When a signaling molecule comes into contact with a cell and its interaction with the receptor begins, the protein begins to activate and triggers multiple biochemical reactions in the cell. As a result, cell reproduction begins.

For the normal functioning of the human body system, such signals must occur at a strictly defined time, otherwise the consequences can be very serious.

It is the increased activity of the receptor that causes uncontrolled cell proliferation, which leads to cancer.

Types of acrylic fabrics

By combining pure acrylic with natural and artificial fibers, new materials with improved properties are obtained. For example, vinyl or polyurethane coating increases the water-repellent properties of acrylic fabric and increases its abrasion resistance.

Polyacrylic

Consists of 95% acrylic fibers and 5% wool, cotton, angora threads. Clothes made from polyacrylic are very warm, comfortable, and comfortable. In terms of quality, it can easily replace things made from angora or natural wool.

In fact, acrylic and polyacrylic are the same material. The prefix “poly” indicates that polymer fibers were used in the production of this fabric.

Modacrylic (modified acrylic)

Polyacrylic and vinyl fibers are used in its production. Curtains and drapes for window decoration are most often made from this fabric.

Microacrylic

Knitted items are knitted from acrylic yarn using a knitting machine and by hand.

Acrylic yarn

Acrylic, acrylic, acrilik, acrylique, PAN (bulk), cashmilon, nitron, orlon, acrylan, dralon, kurtel, prelan - all these are trademarks and names of durable synthetic fiber made of polyacrylonitrile, from which yarn is made that resembles wool in properties and structure .

Contrary to popular belief that acrylic fabric equals wool, this is not true. There are not only similarities between them based on the same characteristics, appearance, scope of application, but also differences.

Acrylic is cheaper to produce. Superior to natural material in thermal insulation properties, strength, shine, brightness of colors, elasticity, lightness, resistance to humidity, and high temperatures. Clothes made from acrylic do not ripple, do not shrink after washing, and dry quickly.

Although there are also disadvantages - the fabric wears out quickly (those who knit acrylic socks know this), pellets form on it, which are difficult to remove, and become electrified. Items made from artificial wool are not as warm as those made from natural wool.

Both materials: synthetic and its natural counterpart have their pros and cons. To minimize the disadvantages of both and improve their quality, manufacturers often produce blended fibers in different proportions. For example, if 100% wool is diluted with acrylic, the yarn does not shrink after washing and its wear resistance increases.

And for those who suffer from an allergic reaction to wool, acrylic knitwear is an excellent replacement.

The emergence of acrylic paints

Another area of application of acrylic is the production of paints and varnishes. They first appeared in Mexico in the middle of the last century, after which they actively began to be produced in the United States and Europe. It should be noted that initially the technology involved the use of alcohol, and paints were used exclusively in painting. However, over time, alcohol was replaced by ordinary water, and the scope of application expanded significantly.

What is made from acrylic and where else is it used?

Acrylic, thanks to the structure of the synthetic material and the use of various techniques of knitting and weaving threads, produces a variety of products. And not only in the textile industry, but also in related industries.

Synthetic wool makes excellent warm clothing, jackets, sweaters for adults and children, and accessories for cold weather (scarves, gloves, hats, socks).

Acrylic with the addition of polyester is used to make soft toys, home textiles, decorative items, curtains, furniture upholstery, sports and travel clothing.

Knitters are well acquainted with knitting threads that contain 100% acrylic or with any additives.

The advertising sector has not neglected the wear-resistant and durable material from which banners, streamers, and signs are made.

Manufacturers produce tents, tents, covers and other outdoor coverings for various purposes from dense fabric resembling awnings.

Rules of care

Each material, depending on the components included in its composition, has features that must be taken into account when caring for the fabric. The manufacturer reports this on clothing tags. But there are also general recommendations that should be followed when caring for products made from it.

How to wash

You can wash it in any way, but it is better to wash it by hand. Not too often and in water up to 30 degrees. At higher temperatures, the item may stretch, deform, and lose softness.

If washing by machine, you need to put two or three items in the drum, placing them in a bag. This will save your clothes from creasing.

To ensure that the fibers retain their original softness, it is recommended to use conditioner when rinsing.

How to do push-ups

It is better to do this manually so as not to disturb the structure of the fabric when drying in a centrifuge, without twisting or squeezing too much. If drying in a machine, do it only at minimum speed.

How to dry

It is advisable to dry acrylic clothes on a horizontal surface, after straightening out folds and creases. Keep out of the sun and away from heating appliances. It is important not to overdry.

How to iron

It is better to avoid this procedure. But if this is not possible, iron with a lukewarm iron through cotton cloth or gauze. If creases form, do not use steaming. This may stretch the edges of the garment unevenly.

Some types of acrylic clothing can be dry cleaned. Permissive information in the form of an icon is indicated on the clothing label.

If the item is slightly dirty, you can not wash it, but try to remove the stains by applying a soap solution to them for 15-20 minutes. Then remove any remaining detergent with a sponge.

Important: before you start washing acrylic clothing, you must read the information on the product label.

Application of material

High-quality acrylic fabric is used in the production of textiles for transport, furniture production (upholstery fabric), and home textiles.

Acrylic materials are used in tailoring. At the same time, they can serve as both the main fabric and serve as a lining. A variety of rugs, carpets and curtains are another option for using acrylic fabrics.

It is used for the manufacture of protective clothing and winter outerwear. Depending on the types of fabric fibers added, knitted clothes and suits are made from it.

This material is also used for the production of advertising banners, awnings, various canopies, awnings and signs. This use of acrylic fabrics is due to their ability to perfectly retain their appearance without deforming even at high temperatures.