There are most hats, blankets, and socks made of sheep wool on the market, and they are inexpensive. Apparently, because of this, buyers are not so careful when choosing a product. Fraudsters take advantage of this and counterfeit “sheep” no less actively than the more expensive camel wool, yak down and cashmere.

“No more than 5% of synthetics in wool yarn is allowed,” says Natalya Konyukova , deputy general director of the cloth factory, “otherwise the yarn is considered half-woolen. There are few pills on woolen products, but synthetics roll up very much. Wool provides noticeable warmth - just wrap your hand in the cloth. But the most effective test is with fire. Set fire to several fibers of the product. Natural sheep’s wool smells like burnt horn and doesn’t melt.”

Question and answer Really warm. What fillers and membranes are used in down jackets? In turn, sheep wool is often used to counterfeit higher quality and more expensive camel wool, yak down and cashmere.

Chinese “masters” were the first to establish such production, then their recipe was adopted in Mongolia and Russia. It is simple: 60% of coarse sheep wool is taken from about 40% of synthetics (acrylic or viscose), to which 2-3% of the raw materials they are trying to depict are mixed.

The fake is then painted in a “natural color”. The colors of cashmere are white, beige-cream, warm gray and café au lait, yak down is gray, light brown (“cappuccino”) and dark brown, camel hair is sandy beige, beige cream, light chocolate. .

How to determine the composition of yarn by burning

Today we have laboratory work.

Today we are setting fire to yarn. Not for the sake of self-indulgence, but for the sake of determining its composition. Experts call this process an organoleptic method for recognizing fiber by burning. For what? Many years ago, you bought yarn, knitted something from it, and put the rest in long-term storage, forgetting to sign it. Or someone gave you yarn without labels, and you don’t know its composition. Or there may be some other situation, and the composition is also unknown. Is it necessary to at least roughly know what kind of animal is in your hands? Is it necessary to know the composition of the yarn? Isn't it enough to visually and tactilely examine the thread and knit the product based on the thickness and color of the thread? No. The color and thickness are very insufficient.

Imagine, without knowing the composition of the yarn, you knitted a product, washed it and... The product stretched greatly in breadth or shrinked greatly. And if your summer T-shirt after washing is very fluffy and resembles a shawl. Or your jumper has been welded so that its fabric has lost its pattern and resembles felt boots. These are not all the troubles that can happen due to a lack of understanding, what kind of yarn lies in front of you?

I suggest you at least roughly determine what you have to work with. Let's set fire to pieces of yarn. I remember we did this at school during home economics lessons, but there we burned fabric. The essence does not change today, since fabric and yarn are made in production from the same materials. So.

We take about 10 cm of yarn and set one end on fire. We look at how quickly the thread burns, what the color of the flame is and the nature of the combustion, pay attention to the smoke, if there is any. As soon as half of the thread has burned, we blow it out sharply and look at the result. As soon as everything has cooled down, we try to rub the combustion product with our fingers, that is, what remains after combustion.

Ball 1. The thread is badly eaten by moths. You don't have to burn it. The thread is natural, wool, quite edible and even very tasty. If the moth that found this ball died of gluttony without having time to leave offspring, you will not find it. Set fire to the thread. Wool doesn't melt. It burns slowly, the flame is weak and flickering, and the smoke smells like burnt feathers or hair. During combustion, black or dark brown ash appears in grains. The cooled grains crumble into powder. Chemists claim that wool is resistant to mineral acids, and is destroyed in hot sulfuric acid and weak alkali solutions.

Ball 2. Silk . This is an animal fiber. It burns like wool, it smells the same, and when burned, its ash also forms in the form of a black ball, which also crumbles into powder. We are talking about natural silk. Rayon is a synthetic.

Tangle 3. Viscose . This fiber has a silky shine. Burns quickly and brightly, does not melt, smells of burnt wood or paper, leaves a light ash. Viscose dissolves in hot dilute and cold concentrated acids. Concentrated alkali solutions cause it to swell.

Ball 4. Cotton . This is a plant fiber. It ignites easily, burns quickly with a bright yellow flame and has a burnt paper smell. When burned, it leaves a white-gray ash. Cotton is not very resistant to chemicals and minerals, mineral acids, but is resistant to alkalis.

Ball 5. Linen . This is also a plant fiber, and when burned it behaves in the same way as cotton, only it extinguishes faster and smolders poorly.

Tangle 6. Synthetics . There are a lot of synthetic fibers in production, and they all behave differently. Acrylic, nitron, acetate, nylon, nylon, polyester, spandex and a bunch of others with unearthly names - these are all synthetics. But they have a common property - they do not burn and do not leave ashes. They melt, leaving a dense ball. This is why firefighters and the Ministry of Emergency Situations do not recommend synthetic clothing. If the flame from natural clothing can be knocked down or extinguished, then the remnants of melting synthetic clothing stick to the body and leave burns. In addition, the smoke that is produced during combustion, that is, during melting, is often very poisonous. That is why in case of fires in large entertainment venues, where everything is decorated with plastic, people die not from fire, but from poisoning and suffocation. But not all synthetics stink so bad. For example, acrylic or melting reminds the smell of fish, acetate smells like vinegar and paper, nylon smells like celery. By the way, the color of the melted synthetic balls can also be different, creamy, bluish, and black. When hardened, these balls do not crumble into ashes, which distinguishes synthetic fibers from natural ones.

To summarize, we can say that fibers of plant origin (cotton, flax and everything that during their life represents grass and trees) when burned smell like burnt paper or wood, fibers of animal origin (wool, silk and everything that walks and eats during life) and makes sounds) when burning they smell like burnt feathers and hair, and fibers of synthetic origin, like all chemicals, can smell like anything and even stink like anything. The ash of fibers of plant and animal origin crumbles, and in most cases artificial ash is sintered into hard balls. I repeat: in most cases. This means that scientists do not stop there and the products of their creativity may soon give natural ones a head start, if they have not already.

Attention! These descriptions only apply to 100% yarn compositions. If the thread is a mixture of different fibers, it may be difficult to determine them, and even more so in their percentage composition. But here too you can fight.

Try to take the thread apart into pieces. If the thread is untwisted, it is often seen that it is assembled from different fibers. Using tweezers, sort these fibers into different piles, estimate the percentage and burn each pile separately, forming a ball from each pile or even twisting the threads.

Stop! They forgot about the most important thing! Safety precautions! Before you start experimenting, protect your hair with a headscarf and prepare the room, remove extraneous odors, and eliminate drafts. After burning one thread, ventilate the room, burn the second thread and ventilate the room again. Be sure to place something non-flammable under the material you are burning. Let it be a plate, a baking sheet from the oven, or a simple sheet of foil from a chocolate bar. It is not recommended to use matches; they are wooden, and their smell will overwhelm the smell of burnt thread and interfere with the experiment. A candle or a simple lighter will help you. Be sure to have water ready so that you can put out a fire that has gotten out of control in time. Remember that some fibers do not ignite immediately, but once ignited, they become excited and do not want to go out.

You can, of course, test the fibers chemically. For example, in nitric acid (HNO3) cotton will dissolve and wool will turn yellow. And if you immerse cotton in a 10% solution of caustic soda (NaOH), it will swell, but wool will simply dissolve.

But you are unlikely to do such experiments at home, it is unsafe, and the necessary solutions may simply not be available at home.

Types of wool yarn

Sheep wool is one of the most common types of wool. As a rule, the name “wool” refers to the wool of sheep. It is found both in pure form and mixed with other fibers. Sheep wool is divided into several types, which differ in the thickness of the hair. Wool can be of varying degrees of softness depending on the breed of sheep, as well as the time of year when it was collected - wool obtained from spring shearing is softer.

Merino wool is the highest quality wool. It is obtained from sheep of a fine-wool breed; accordingly, the yarn from such fiber is thin and soft. The high quality of wool is also maintained by spring shearing—fine-wool sheep are sheared only in the spring, once a year, when the wool is thinnest and most uniform. Merino wool is ideal for the production of yarn for knitting children's clothes. It is also used for knitting things for allergy sufferers, since there is no reaction to it.

Among the distinctive advantages of merino wool yarn is its excellent ability to retain heat, while the skin in knitted clothes from this yarn “breathes” well, so the body does not sweat.

Semi-fine wool (medium type) is a fiber obtained from meat-wool sheep (non-fine wool breed). This wool is coarser and the fiber is thicker, so the quality of the yarn is lower than that of merino.

Poyark wool (Baby Merino) is the wool of lambs aged 4-7 months. Very fine hair compared to the hair of an adult sheep.

Camel wool is an inexpensive, but not very popular type of wool yarn. Its unpopularity is largely due to the poor choice of colors - dark or black shades. Many people choose the natural color of wool for needlework - light brown. The thing is that it does not bleach, so there is no way to give it the desired tone. Despite this, it is often chosen if they want to create truly warm clothes due to its high quality and excellent ability to retain heat.

The structure of camel hair differs from other types of wool - it does not have a scaly structure inside. In this regard, it has distinctive properties, of which the following can be noted:

- more than 2 times lighter than sheep wool;

- not electrified;

- has very high hygroscopicity;

- resistant to contamination;

- has a healing effect - it is recommended for people suffering from circulatory disorders, and thanks to lanolin (animal wax found in the internal cavity of hairs) it helps with diseases of the musculoskeletal system.

However, things made from camel hair are not suitable for everyone: on the one hand, the hard hairs create a tingling effect and, thus, improve blood circulation thanks to a kind of massage, but on the other hand, such things “prick” and therefore are not liked by children and those with sensitive skin .

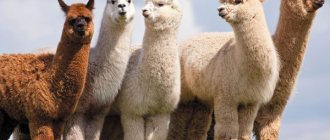

Alpaca is the most expensive and high-quality wool. The yarn is obtained from the wool of alpacas (llama, belongs to the camel family). Animals live in high mountain areas with extreme climatic conditions, and therefore their fur must protect them from adverse conditions. According to its properties, it is soft, long and thin and has a pleasant silky shine.

No wool compares to alpaca fur. Their wool has no fat, so products made from wool yarn do not get dirty for a long time.

The advantages include:

- 7 times warmer than sheep wool;

- does not become dirty for a long time;

- does not wrinkle;

- not prone to pilling and matting;

- does not cause allergies;

- practically waterproof;

- finished products made from alpaca wool look excellent and durable.

The disadvantage of yarn is its high price.

Mohair is made from the wool of Angora goats, which are grown only in three regions of the world (Ankara in Turkey, Texas and South Africa). Wool is incredibly soft, so you won't find 100% mohair - wool yarn will simply disintegrate into individual fibers. The yarn composition does not contain more than 83% mohair, due to the peculiarities of the technological process and the resulting quality of the output yarn. Wool yarn made from mohair opens up wide scope for creativity thanks to a rich palette of tones (goat hair is easy to dye). Mohair is ideal for knitting openwork patterns - things turn out airy, but at the same time warm. A striking example is Orenburg down scarves.

Advantages of mohair yarn:

- very soft wool yarn;

- durable;

- has a strong shine;

- easy to clean from dirt;

- Mohair items are very light and warm.

Knitting from mohair is a pleasure, and you don’t want to let go of mohair items, but due to the softness of the fiber, very delicate care is required, otherwise things will quickly lose their appearance.

Angora (angora) is a wool yarn obtained from the down of Angora rabbits. However, there should not be a lot of fluff in the yarn: the optimal content is 20%, otherwise it will be impossible to knit from the yarn, as it will disintegrate. The exception is high-quality angora wool yarn, but its price is high. Typically, rabbit down is used as a complement to regular or merino wool, and is also mixed with acrylic.

Advantages of Angora:

- soft and fine wool yarn;

- light;

- warm.

Flaws:

- not very durable;

- it is difficult to work with wool yarn - there is no way to firmly secure the thread due to the fluff coming out;

- things cannot be washed (they cannot even get wet) - only dry cleaning.

Cashmere - the thick and thin fluff of Tibetan highland goats is used for yarn, which is combed from the chest and belly of the animals. Like other types of down yarn, it does not exist in its pure form: down is too soft to hold its shape, so items made from pure cashmere would quickly stretch out under their own weight. Typically knitting yarn contains 30% goat down. Cashmere yarn is one of the most expensive.

Benefits of cashmere:

- soft wool yarn;

- warm (Tibetan goats live in harsh climatic conditions, where in summer up to +500C, and in winter - from -400C);

- pleasant for knitting, and things turn out beautiful and airy.

Disadvantages of cashmere:

- cashmere items require delicate care and wear out quickly;

- yarn price.

Against the grain. How to distinguish natural material from fakes?

There are most hats, blankets, and socks made of sheep wool on the market, and they are inexpensive. Apparently, because of this, buyers are not so careful when choosing a product. Fraudsters take advantage of this and counterfeit “sheep” no less actively than the more expensive camel wool, yak down and cashmere.

“No more than 5% of synthetics in wool yarn is allowed,” says

Natalya Konyukova , deputy general director of the cloth factory, “otherwise the yarn is considered half-woolen.

There are few pills on woolen products, but synthetics roll up very much. Wool provides noticeable warmth - just wrap your hand in the cloth. But the most effective test is with fire. Set fire to several fibers of the product. Natural sheep’s wool smells like burnt horn and doesn’t melt.” In turn, sheep wool is often used to counterfeit higher quality and more expensive camel wool, yak down and cashmere.

Chinese “masters” were the first to establish such production, then their recipe was adopted in Mongolia and Russia. It is simple: 60% of coarse sheep wool is taken from about 40% of synthetics (acrylic or viscose), to which 2-3% of the raw materials they are trying to depict are mixed.

The fake is then painted in a “natural color”. The colors of cashmere are white, beige-cream, warm gray and café au lait, yak down is gray, light brown (“cappuccino”) and dark brown, camel hair is sandy beige, beige cream, light chocolate. .

Caring for wool products

Products made from wool yarn require special care. Wool products of any kind are not immune to problems with pilling and deformation.

- Woolen items are best washed by hand. In some cases, you can also use the delicate cycle in your washing machine. For washing you need to choose special detergents.

- Wash gently, without strong physical impact. Do not twist items after washing. All this can cause a loss of elasticity and strength of the yarn.

- Do not dry items in the washing machine. Products lose shape and may shrink in size if the temperature is too high.

- To dry wet woolen items, carefully lay them out on a flat surface. Under no circumstances hang them on a hanger immediately after washing! If you hang them, things will stretch out a lot.

- Do not dry woolen items on heating appliances.

- Do not iron things with a hot iron. Use a clean white cloth to iron the garment through, or gently steam the volume back into the garment.

As for the features of caring for various types of wool yarn, there are nuances:

- Products made from mohair yarn must be washed carefully. The water should be at room temperature. It is better to use mild shampoo for washing.

- For Angora, dry cleaning is the ideal option.

- Products made from alpaca wool are best not hung, but stored rolled up.

We give blog visitors a 5% discount

When placing an order, enter the promo code

BLOG

Wild treasure of Mongolia

“Cashmere, camel and yak down are not really wool,” says Odonchimeg Yongdon , an entrepreneur from Mongolia. — This is the undercoat of a camel, yak or goat (cashmere).

The materials are unique - there is nothing lighter or warmer. Camel also contains lanolin, which penetrates the human body through the pores of the skin and has a beneficial effect on health. All materials are very delicate - if you walk on the floor in camel socks, they will wear out in a week. But if the clothes are not subject to friction, they can be worn for years.” The listed types of wool are the most expensive; Let's say a cashmere cardigan is unlikely to be cheaper than 15-20 thousand rubles. “The price of the product, by the way, sometimes helps to identify a fake,” notes Odonchimeg. “For example, socks made of camel wool cannot cost 250-300 rubles - their retail price is at least 600.”

The main reason for the high cost is the difficulty of obtaining raw materials. Camels, goats and yaks are semi-wild animals. To comb out the fluff, you must first catch them. And if it is not difficult to catch and tie a goat, a camel is more difficult, but possible, then no one can hold a yak. And the production time is also sharply limited.

Sheep under camel

“With a guarantee” it is much more difficult to distinguish cheap wool from expensive undercoat than sheepskin from synthetics, warns a Mongolian expert. But it is possible.

“First of all, in terms of texture: the fake is harder and rougher to the touch, the fibers are thicker,” explains Odonchimeg. “It also squeaks if you rub one part of the product against another. “Sheep” is heavier. For example, fake leggings will slip under their own weight, but camel and yak leggings will not. Another sign is the smell. Any wet fake just reeks of sheep. Natural camel, yak down and cashmere have a faint odor, completely unlike sheep.”

“There are peculiar Russian fakes,” the expert added, “when, for example, a coat whose fabric contains no more than 10% cashmere (and this is indicated on the label) is called cashmere. The price is high, like a cashmere product. It is not right. I believe that if they say “camel”, “yak”, “cashmere”, then the content of these materials should be one hundred percent.”

How to check the naturalness of silk: the best proven methods

Natural silk is the finest threads obtained by heat treatment of silkworm cocoons. Under the influence of temperature, from 400 to 1400 m of thread can be produced from a cocoon. Because the process of making silk is time-consuming and labor-intensive, the natural fiber is expensive.

Nowadays silk fabrics can be counterfeited so that they are difficult to distinguish from natural ones. And if the label says 100% silk, this does not mean that the product is made from natural raw materials. There are several secrets and conditions for checking silk for naturalness.

What does natural material look like?

How to understand that you have natural material in your hands

Natural silk fabric is divided into:

- Satin is a strong, durable, hygroscopic, shape-stable and beautiful material. Natural silk satin is a fairly heavy, recognizable, elegant and expensive fabric. Products made from it shimmer beautifully in the sunlight.

- Rock silk is a fabric made from a mixture of gold and silk threads for sewing clothing for the highest ranks of clergy. The most expensive type of silk fabric.

- Gas is a light and delicate, breathable, light-permeable, hypoallergenic fabric. Airy canvases are used for decoration.

- Crepe. It practically does not wrinkle, drapes well, and is wear-resistant. There are many varieties of crepe fabrics, for example, crepe de chine and crepe satin, the main advantage of which is their naturalness.

- Organza is a fabric that does not wrinkle, does not shrink, retains its shape, is durable, and transmits light. This type of silk is used for decorating and sewing various products.

What is artificial silk

Artificial silk, also known as viscose, is a material that is difficult to distinguish from natural one. Viscose has a completely smooth surface, soft and elastic. If the natural one is made from silkworm cocoons, then the artificial one is made from cellulose. Viscose is also natural, but has different properties. Artificial silk is more reminiscent of cotton fabrics in its qualities. Viscose was created to imitate it.

Viscose

Important! Do not confuse viscose and synthetic silk. Synthetic is made entirely from chemical fibers.

Properties of artificial silk:

- soft;

- easy;

- smooth;

- allows air to pass through well;

- almost not electrified;

- draped;

- lasting;

- hypoallergenic.

The disadvantages of artificial silk include:

- does not allow air to pass through well, does not breathe;

- wrinkles;

- can tear easily when wet.

It is widely used in everyday life, as it is much cheaper than natural silk. Artificial fiber fabrics are often used in clothing, curtains, accessories, and tablecloths. They are also used to make blankets and bed linen. Products made from this fabric are soft and comfortable, but require careful care.

Bed sheets

Using modern technologies, three types of viscose fabric have been developed:

- Modal. This type of viscose is made only from beech and eucalyptus. Modal products are durable, elastic and have high hygienic properties.

- Lyocell. To obtain this type of fiber, cellulose is treated with methyl morpholine oxide. The threads are quite strong and look like natural silk. The price of such material is quite high.

- Siblon. Made from coniferous wood. The fabric practically does not wrinkle and does not shrink.

Products made from viscose require delicate care. It should be washed at a temperature of 30-40°C on a hand or delicate wash cycle.

Delicate care

Difference between wool and synthetic

Do you want to know how to distinguish wool fabric from artificial fabric, but don’t know how to do it? You can find out the answer to this question based on the special properties of these types of fabrics, which will be discussed in this article. Wool is a woven fabric made from natural fibers. They are made from hair sheared from animals living at home, for example, sheep or camels.

To give the fabric special properties, non-natural fibers can be added during its manufacture, but their volume will always not be more than ten percent of the composition. Since wool fabric is considered real, its distinguishing feature is that it does not generate static electricity.

Also, when you scrunch the fabric in your hand, it doesn't make that unpleasant sound that gives some people goosebumps.

How does natural wool burn?

Wool

can also be distinguished by the structure of the fibers - since they are made of hairs, then, like the latter, they do not have a solid structure, but various branches. If you set fire to wool fiber, it begins to smoke and smells like burning, and the burnt part easily crumbles between your fingers.

Synthetics are made from artificial fibers, which consist of various compounds of polymer materials. During the production process, different bases are mixed with each other, and a homogeneous mass emerges, which is then used to create artificial fiber.

A distinctive feature of artificial fabric is the static electricity it creates, which can be seen in the dark in the form of small flashes. At the same time, when wrinkled, synthetics make an unpleasant sound, similar to a quiet grinding sound.

Fire rain effect. Sparks from steel wool.

One day.

And among other things, when ignited, synthetics melt like plastic, and the charred part of the fiber turns into a solid ball that does not crumble and breaks off at the very base. The main difference between wool and synthetics is that the first fabric is considered real, and the second is artificial. Thanks to this, wool does not create static electricity, and synthetics have this ability.

Also, if these materials are crumpled in your hand, then the wool fabric does not squeak, but the artificial one makes such a sound. And the most important distinguishing feature is that wool fiber burns, crumbles between the fingers and has a characteristic unpleasant odor, while fiber made from synthetic materials melts, forming a lump, does not break in the hand and smells like burnt plastic.

How to distinguish artificial from natural and synthetic

Due to the difference in material costs, it is very important to be able to identify and distinguish artificial material from natural and synthetic ones. Some manufacturers may use a mixture of them in products. At the same time, the quality of the product becomes worse, and the cost for the buyer remains high.

In appearance, viscose is well made, often similar to natural silk fiber. There are several simple methods for identifying natural silk:

| Properties | Natural | Artificial | Synthetic |

| Shine | Delicate and matte | Pronounced metallic | No |

| Ability to absorb moisture | High, up to 40% of its own weight | Average, 12-15% of its own weight | Low, no more than 5% of its own weight |

| Combustion | Sintered by balls | Burns with the smell of burning paper | Burns quickly and melts like plastic |

| Air permeability | Increased | Average | Low |

| Hypoallergenic | Does not cause allergies | Partial chemical composition may cause allergies, but the likelihood is not high | May cause allergies due to chemical composition |

| Strength | high | Low when wet | Average strength |

| Electrification | Not electrified | High electrification | Accumulates static electricity |

How to identify natural material

The surest way to test natural material to distinguish it from artificial material is to watch how silk burns. Synthetics will immediately begin to melt. The artificial thread will catch fire and give off a burnt paper smell. And natural silk burns with the smell of burnt hair or wool.

You also need to check whether the silk wrinkles or not. To do this, squeeze the material in your hand, and if folds remain on it, then it is not natural silk.

Real silk

Products made from natural silk are quite expensive, but the quality speaks for itself. They will last much longer than the same ones made from artificial fabrics. This is why it is so important to understand fabrics and check their quality.

Specifics and properties of sheepskin fur

Sheep fur produces lanolin or a special wax, due to which the natural material has a healing effect. It relieves fatigue, swelling and inflammation, improves blood circulation and accelerates skin healing, absorbs harmful germs and bacteria. In addition, sheepskin does not cause allergic reactions, which is important for allergy sufferers and small children.

Sheepskin maintains body temperature, so in such clothes it is not hot or cold, but comfortable. At the same time, the material absorbs moisture without compromising quality. It dries quickly and ventilates easily, promoting air circulation. Soft sheepskin will relieve joint pain and fatigue, and create an atmosphere of coziness, warmth and comfort in your home.

Among the types of sheepskin, we note Tuscany. This is an Italian breed of sheep, the skin of which is often used to make sheepskin coats. Mouton, astragan and astrakhan fur are also produced from natural sheepskin. Such materials form the basis of fur coats and short fur coats, coats and vests, capes and jackets. We offer several methods that will help distinguish natural sheep fur from fakes.