Bumazeya, or Bombazin, is a fabric that has an incredibly interesting history. It is still not known for certain where this fabric came from. Some believe that it is from Italy, others claim that it is from France, and still others believe that its roots lie in Spain. And most importantly, from the name of the fabric its origin is also unclear. Bumazeya is a Russian interpretation of the original name bombazine, which goes back to the Spanish or French roots of the product. "Bombazine" or "bombasin" are translated from Spanish and French, respectively, as "cotton" or "cotton fabric".

Brief history of origin

Historians suggest that the first production of fabric dates back to the Middle Ages. There is no consensus on the origin of the material. Some believe that the first mention of it belongs to Italy, others - to France.

Even experienced textile workers who have an idea of what paper is, find it difficult to answer where the name of the material came from. Translated from French, “bombasin” means “silk”, and from Italian and Spanish the word “bombazine” is translated as “cotton” or “paper”.

Medieval sources mention a description of bombasin silk fabric. Later, before the advent of long and medium fiber cotton, bombazine was produced by weaving linen warp and silk weft.

In Russia, the fabric was called bombazin. Initially used in sewing mourning clothes.

Start and features of production

According to historical research and linguistic examinations, there are two versions of the origin of the name Bumazeya:

- from the French word "bombasin"

- from Italian "bombazine"

therefore the material is also called bombazine.

As for the origin of the fabric, historians also disagree. Some argue that its production was first launched in the 13th century in Valencia. Others are sure that Milanese masters began weaving it in the 14th century. The rest lean towards medieval France. The most common belief is that bambazeya appeared in England, during the reign of Elizabeth I. This textile gained wide popularity in our country in the 17th century under the name “bambazeya”.

However, the bumazea did not immediately have the appearance to which we are accustomed. Initially, this was the name given to dense silk, and then to a material with a linen base, which strengthened loose textiles, and a cotton weft. The first products made from bombazine were of discreet colors, most often in dark tones. This fabric was used for sewing budget mourning dresses, while light shades were suitable for sewing everyday clothes.

Later, bleaching was used to process bombazine. Warm underwear for the cold season was made from this material. Soon paper fabric was painted with multi-colored patterns - such products were practical and firmly established in the everyday wardrobe of women and children.

When long-fiber raw materials of Peruvian origin appeared on the market, bumazea acquired an entirely cotton composition. Then the material began to be created in several variations - with short, medium, long pile.

The production process of bombazine comes down to two main stages:

- weaving cotton threads using twill or plain method;

- bringing out the villi that form the backcomb to the wrong side.

Composition and description

Fumazeya is a natural fabric made from linen and cotton threads (or only cotton), often twill, less often simple weaving. At the production stage, small fibers are brought to the wrong side, forming a pile.

The material is soft and pleasant to the touch. Fumazea is thicker than regular flannel and thinner than flannel, differs from these materials in density

.

Depending on the fibers used, two types of paper are distinguished. Medium and long threads produce high-quality fabric with improved characteristics. Its cost is not much higher than standard low-grade cotton wool, woven from short cotton fibers. But at the same time, the material is inferior in wear resistance.

What standards are used in production? What do they take into account?

GOST 29298-92 establishes for cotton fabrics:

- technical requirements for finished materials;

- test methods, acceptance rules;

- safety standards for yarn, drugs, dyes;

- transportation and storage standards.

The GOST states:

- painting requirements;

- permissible size deviations;

- changes after treatment;

- standards for breaking load, abrasion resistance;

- physical and hygienic requirements;

- labeling and packaging standards.

Characteristics and properties

Material made from natural raw materials, produced in the Russian Federation, complies with the standards of GOST 29298 - 2005. The main properties and characteristics of paper are shown in the table below:

| Index | Meaning |

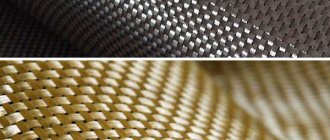

| Weave weave | Twill, less often - simple |

| Canvas drawing | Plain bleached, plain dyed, printed |

| Structure | The front (right) side is smooth, the back side is short-combed |

| Cotton fibers used | Short; medium for the production of high quality fabrics with higher density (carded yarn) |

| Density, g/sq.m. | 160 – 265 |

| Hygroscopicity | 6 – 12%. The fabric absorbs moisture well and wicks it away quickly |

| Breathability | Average |

| Vapor permeability | Excellent |

| Electrification | Minimum |

Before working with the material, it is worth considering the property of paper: it is characterized by shrinkage. Therefore, it is recommended to decate the fabric before cutting.

Peculiarities

It was clarified a little higher what bumazea is, now it’s worth learning about its features. Thanks to its natural cotton composition and manufacturing features, cotton wool has the following features:

- hypoallergenic and hygienic;

- warms well, while allowing water vapor and air to pass away from the surface of the skin;

- comfort and softness to the touch;

- low price.

Advantages and disadvantages

The advantages that cotton wool has have made this material popular, despite the fact that knitted fabrics are increasingly replacing woven ones. The advantages include:

- Natural composition ensuring hypoallergenic and environmentally friendly material.

- Softness.

- Ability to retain heat.

- Excellent drape.

- Hygroscopicity.

- Affordable price.

Bumazea has few disadvantages. If you properly approach the preparation of the material and care for products made from it, they will not become a problem. The disadvantages include the following qualities:

- creasing;

- rapid abrasion of the pile surface;

- color instability;

- peelability;

- shrinkage after the first wash.

What does bumazea look like?

Bumazeya is a fairly dense twill weave fabric with a brushed back side. This brushing makes paper products warm, pleasant to the touch and soft. In general, the properties of fumazea are similar to that of bike, but it is thinner and lighter.

The main advantages of this type of fabric are:

- Environmental friendliness,

- Softness,

- Thermal conductivity,

- Good properties for drapery,

- Hypoallergenic,

- Affordable price.

Among the disadvantages of the material, one can highlight poor wear resistance; this material is short-lived, quickly wears out and becomes unusable.

Types of bumazea

There are several types of fabric:

- harsh;

- bleached;

- smoothly painted;

- Printed;

- with reserve napping (with the formation of a fleecy pattern on the front side);

- cord

Plain colored paper is represented by samples of rich tones. Its distinctive property is that the fabric does not lose color saturation for a long time. This is facilitated by the method of applying the dye: the canvas is placed in a container with pigment for several hours. Thanks to this treatment, the surface of the textile has a uniform structure.

Printing is done by printing a design on one or both sides. This method allows you to get a durable print without changing the structure of the canvas.

Bleached is the most environmentally friendly and safe option. Therefore, material made without the use of dyes is most often used for sewing children's underwear and bedding sets. Army underwear is made from it.

Reserve napping is a special type of processing in which individual ends of the fibers are brought to the front side, forming a relief pattern with alternating smooth and fleecy areas.

Fumazeya cord additionally undergoes a mercerization stage and is used for the manufacture of insoles and linings in footwear.

Application

Natural fabric gives a feeling of comfort and coziness. Therefore, industrial production uses paper for sewing clothes and other products:

- Home textiles for the whole family: dressing gowns, pajamas.

- Baby supplies: bed linen, clothes, diapers. The soft and hypoallergenic composition is suitable for use by young children.

- Linen for the army. It does not interfere with soldiers during heavy workloads and keeps them warm.

- Curtains. The soft fabric drapes well, allowing you to create beautiful waves.

- After impregnation with reinforcing compounds, paper cord is used to create internal parts of shoes and as a base for artificial leather.

Hygienic, natural and warm cotton wool is well suited for sewing winter children's and women's clothing, as well as warm men's shirts.

What they sew - application

Bumazeya is widely used in sewing clothes for the home, linen group, and bed linen. It has also found application in the shoe industry and medicine. Due to the fact that the fabric easily forms soft folds, it is used in the interior - curtains, covers and bedspreads are sewn to match.

The structure of the fabric and its softness limit the range of applications. Formal suits and elegant dresses are not made from fabric. But it is often used as a material for cozy home clothes. The following products are sewn from paper:

- Winter bedding;

- Pajamas, nightgowns for children and adults;

- Robes, home suits;

- Diapers, vests, rompers and blouses for babies;

- Products of the linen group (military linen);

- Curtains and bedspreads;

- They make insoles and linings in shoes.

What type of fabric is this?

Bumazeya is a warm, dense, soft cotton fabric with a light brush on the reverse side.

Produced in textile factories. Paper fabric is made from cotton yarn on a loom.

What does paper fabric look like?

The twill weave method is used. In twill weave, the yarn strands are joined asymmetrically. The cross thread (weft) overlaps 2 or 3 warp threads. Cotton yarn with different characteristics is used for weft and warp. The backcomb is created using napping machines. The ends of the weft yarn fibers are brought to the surface.

The canvases are processed, bleached, dyed, and designs are applied. The material is used to produce warm home clothing and army linen. The fabric is used for technical purposes. Clothes, stage costumes, curtains, and jewelry are made from premium grade paper.

Care instructions

Despite the fact that cotton wool consists of natural fibers, it requires special care. To preserve the appearance of the fabric and reduce the peelability of the pile surface, it is recommended to follow these rules:

Before cutting, it is advisable to wash the fabric in warm water to shrink it or decate it.

Washing should be done using mild detergents on a delicate cycle, or even better - by hand. The water temperature should not exceed 40 degrees.

It is prohibited to use bleaches for white paper at home.

Drying should be done in a straightened form, protecting the fabric from direct sunlight (this is due to color instability).

Iron products only after drying and on the reverse side.

Application area

izdelie-5

izdelie-6

- Fleeced footer, what kind of fabric: properties, types, what temperature it is suitable for

In past centuries, black paper was treated with respect: mourning clothes were sewn exclusively from it until the 20th century.

Today, fleecy material has a more optimistic purpose.

For centuries, we have been taking care of people. It can be found, perhaps, in every home. Soft, gentle, extremely pleasant and, at the same time, inexpensive, it gives everyone a nice homely warmth and comfort.

Customer Reviews

Vladlena Mikhailovna, Arkhangelsk:

— I don’t sew myself. But I really like things from paper. I buy for myself and my grandchildren. Such things are warm and cozy. I read about the characteristics of bumazea, they consider it short-lived. But it’s inexpensive, and it doesn’t matter that it doesn’t last long. We'll wear them out and buy new ones. One bad thing is that it can be difficult to find among the abundance of Chinese knitwear.

Lyudmila Vasilievna, Almetyevsk:

— I sew for my family myself. I really like Bumazea. It is easy to sew from it, and ready-made items are pleasantly soft and warm to wear. Pajamas, dressing gowns, and shirts for the winter season are very practical and cozy. It's inexpensive and lasts a long time. The children are happy and so am I.

Karina Stanislavovna, Moscow:

“Before, I didn’t know what bumazeya was.” I learned about it when I was learning sewing. Then I had a child, and paper items filled the shelves of my closets. The only thing that upsets me is that the pellets appear quickly. Maybe I'm doing the laundry wrong. But in principle, I like things that are soft and warm, especially new ones.

Expert opinion

Alyona

Fabric expert and technologist Alena Khlebnikova is ready to answer your questions.

Write to us

Write your review or to our expert

What purposes can this fabric be used for?

The following are made from paperweed:

- insoles, inner parts of shoes;

- linings for clothing;

- backpacks, bags.

They sew from it:

- military warm underwear, foot wraps;

- diapers;

- clothes, bedding for children;

- robes;

- nightshirts;

- pajamas;

- sweatshirts;

- jackets

The materials drape well. The interiors of cafes, restaurants, and apartments are decorated with paper curtains in oriental style. High-grade fabrics are used for dresses, jackets, and stage costumes.