Description of waffle fabric

Bleached waffle fabric, sometimes called waffle fabric, is a quality cleaning material.

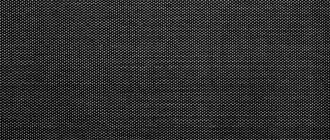

It can be used to wipe not only dirt and liquids, but also to wipe your hands and face. Budget towels are also made from bleached waffle fabric, which are widely used in factories and railways. The waffle fabric received its name due to its checkered structure, which is why it resembles confectionery waffles. The waffle fabric is made from 100% cotton, due to which it absorbs moisture very well.

But the ability to absorb moisture also depends on its quality, the most important indicator of which is density.

Applications and care

The most extensive area of application for fabric with a waffle surface is, of course, towels for various purposes.

Their advantage is low price, hygiene, as well as small volume during storage and transportation. White towels are widely used in medical institutions, railway transport, budget hotels - wherever the rules require processing linen at high temperatures. Plain-dyed thick fabric is used for bathrobes, slippers, and various bathroom accessories. The printed material is used for kitchen towels, potholders, napkins, etc. In addition to household use, waffle fabric is used as a cleaning textile, napkins for wiping components of various industrial equipment, as well as glass and other surfaces.

This fabric can withstand all machine wash cycles. White material can be washed at high temperatures using bleach; for colored fabric, use water at a temperature of 40 degrees. Ironing is done in the “Cotton” mode; if necessary, steaming can be used.

Wafer width

Another characteristic of bleached waffle fabric is its width. Currently, waffle sheets are used mainly in the following widths:

- 45 cm, one of the popular sizes of waffle sheets. Convenient for cutting towels.

- 50 cm, a less used size, since the standard size of towels is 40x70 cm or 40x80 cm, respectively, trim remains when cutting.

- 80 cm is also a fairly used size, again due to the convenience of cutting towels.

Also, sometimes on the market there is a size of 40 cm, this is nothing more than an 80 cm roll cut into 2. It is interesting to some consumers, but the disadvantage of this size is that 1 edge remains unprocessed (the edge of the cut). Other “factory” sizes have both edges processed.

Advantages and disadvantages

Why do we value waffle towels so highly?

- natural;

- environmentally friendly;

- absorb one and a half times more than smooth ones;

- serve for a long time;

- It's inexpensive.

This is a bargain. Even after the towel has become frayed at the edges, you can:

- trim and hem (it will be like new);

- cut out good pieces and use them to make patchwork home textiles;

- use as patches;

- sew toys from it and much more.

There are no disadvantages to waffle towels.

Nowadays, there is simply a huge selection of waffle fabric products on the market, but a wide selection does not always mean high quality material. Quite the opposite - there is a very high probability of running into a low-quality product. How to distinguish one from the other? Remember the characteristics of the waffle towel described above and carefully inspect the product, ask the seller to unwrap it. Feel it. High-quality fabric is soft, pleasant to the touch, quite dense (at least it holds its shape well) and has a uniform texture. If the robe or dress does not meet these requirements (shapeless, there are cuts, tears and tightening), you should not spend money.

Wafer density

At the moment, in Russia, fabric with a density of 120 g/m2, 145 g/m2 and 165 g/m2 is in demand, less often fabric with a density of 200 g/m2 and higher. Waffle fabric is supplied at retail in rolls of 50, 60, 70 linear meters, and wholesale in bales. A bale is several rolls, usually 5-6, packed in plastic film, packaging fabric or paper. Most often there are 250 - 300 linear meters in a bale. m.

Waffle fabric in Russia is produced in accordance with the specifications of a specific manufacturer, or according to GOST 11027-80. From 01/01/2016, a new GOST for wafer fabric 11027-2014 was introduced, this means that now all documents confirming quality are issued for compliance with the new GOST, but old ones issued earlier will be valid until the expiration date.

History of creation

The history of waffle fabric originates in Turkey, where the Turkish towel was invented. In the city of Bursa, waffle fabric was first discovered, various studies were carried out here and experimentally tried to obtain a fabric of good quality, as well as safety and durability. In a relatively short period of time, waffle fabric spread throughout the country and the world. Thus, from the beginning of the 18th century, the first products from this fabric appeared, which included only cotton threads. It was an extremely durable and reliable material; using natural threads, absolute safety and high quality were achieved.

It should be noted that the first towels made from waffle fabric were made by hand; it was a very technologically difficult and time-consuming process, which directly reflected the high cost and relatively low availability. This manual production made it possible to produce no more than four towels per day. At that time, a waffle towel was considered a luxury and only wealthy people could afford it. The high cost slowed down the widespread distribution of this fabric throughout the world.

Currently, waffle fabric is as accessible as possible and is not an expensive material. A special technological process allows us to produce products from this fabric in large volumes and at a budget price. Due to many advantages, wafer fibers are very in demand and popular. Today, waffle towels are an integral part of any kitchen.

Manufacturing technology

Currently, the scale of production of wafer sheets has become significant. The material is produced automatically. The technology includes three stages:

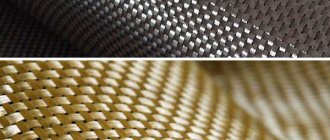

- Production of gray fabrics using complex weaving.

- Cleaning and bleaching of fabric.

- Painting or printing (the design is applied using a roller).

The material for printing is made in a special way for better perception of the design.

For a separate type of textiles for technical purposes, harsh fabrics made from unbleached yarn are used. This fabric absorbs moisture less well and is mainly used in cleaning. Its color is gray-beige.

Advantages and disadvantages

Waffle fabric has a number of advantages over natural materials. The main advantage is considered to be high hygroscopicity. The fabric is capable of absorbing moisture up to 300% of its own weight.

Other advantages include the following qualities:

- natural composition;

- environmentally friendly and safe (does not cause allergies or skin irritations);

- strength;

- good air exchange;

- ability to retain heat;

- high wear resistance;

- does not leave lint when wiping the surface with a “waffle” napkin.

Compared to other cotton materials, the fabric has no disadvantages. Among the minor disadvantages, it is worth noting the vulnerability of the structure to mechanical stress: sharp and piercing objects can form puffs on the canvas.

Secrets of caring for a waffle towel or how to wash a kitchen towel

Waffle towels are universal, but most often housewives use them in kitchens. They perfectly absorb water and fat, are easy to wash, dry very quickly and are easy to iron. Thanks to the special cross-waffle weaving of cotton threads, these towels do not wear out for a long time and retain their original appearance.

Wash waffle towels in water at 40 degrees by hand or in a machine . However, any detergent is suitable for them. Moreover, white waffle towels can be bleached and chemically treated. Such “heavy artillery” cannot be used for colored products. You can twist waffle towels at the highest speed. They are also resistant to drying (natural and using technical devices).

How to choose quality material

The quality of the canvas can be checked in the following ways:

- Request a quality certificate from the supplier. The manufacturer or distributor must always have a quality certificate for the products manufactured and provide it to the consumer upon request.

- By external signs:

- the side edges should not crumble;

- the cells should not differ in shape and size in different areas of the fabric;

- to the touch, the perimeter of the cell should be thicker than its center;

- the material itself must be neatly folded (rolled);

- the fabric must have a uniform color; gray or dark marks are unacceptable.

- Wipe the wet glass with a piece of cloth. A high-quality product instantly absorbs moisture without leaving streaks. If there are stains on the glass, it may contain synthetic impurities.

Characteristics

To find out more about waffle fabric, what it is, and what properties it has, a table describing the characteristics will help:

Properties | Indicators |

| Raw material type | Natural plant |

| Thread type | Carded mercerized |

| Fiber composition | From 100% to 85% cotton |

| Weaving method | Complex (combined) |

| Density, g/sq. m. | 80 – 240 |

| Water resistance | No |

| Hygroscopicity,% | The ability to absorb moisture reaches up to 300% |

| Moisture absorption rate | High |

| Air exchange indicators | Good |

Open to see the entire table

| Vapor permeability | Optimal |

| Standard fabric width, cm. | 40, 45, 50, 80, 150 |

| Wear resistance | High |

| Electrification | Absent |

| Fabric sides | Double- and single-faced |

| Palette | Plain colored plain fabrics, printed, bleached, gray |

| Manufacturers | Russia, Belarus, Uzbekistan, China, Türkiye |

| Standardization | GOST 11027 – 2014, 11027 – 80 For careless linens GOST 8737-77 |

| Price | Low: from 19 rub. for 1 meter |

Areas of application

Waffle fabric has become very common both in everyday life and in modern production. Let's look at what is made from modern wafer material.

- Towels are small in size and quite large. These can be products for use in the kitchen or in a bathhouse, sauna, massage, for personal needs (intimate hygiene) - the type may directly depend on the existing density of a particular product. Such towels are often used by athletes, as the products are highly absorbent. The towel fabric is also very soft. You can often see this kind of towels in trains, hotels, kindergartens and hospitals: they boil easily, are not very expensive and will last quite a long time.

- Robes for various purposes are sewn. Sometimes these are bathrobes, but you can also find bathrobes for everyday wear. It is quite comfortable to sit in such a robe after visiting the steam room, as the fabric will quickly absorb all the sweat. This material also makes excellent soft slippers and comfortable turbans for drying hair.

- Textiles for the kitchen include various potholders , small towels for cleaning, thick covers for a teapot, and large tablecloths. From a large piece of material, you can cut napkins of the required size and small towels in order to effectively wipe washed and therefore wet dishes, or wipe a noticeable speck of grease from the table. Such a cloth can then be easily washed, and there is absolutely no shame in throwing it away and getting a new one. You can sew this kind of rag for everyday cleaning yourself.

- Rags and rags for complete cleaning are in great demand in medical institutions, companies providing cleaning services, in kindergartens and schools. Suitable for high-quality wiping of glass and mirrors, they can be used to wipe glasses, various surfaces of a car and its parts, and can wipe off dust from office equipment. Wafer fabric is used during repairs: you can quickly wipe off fresh paint and varnishes from the skin.

- Due to its resistance to elevated temperatures, the fabric is often found in the oil industry and in the metallurgical field .

- And also, waffle fabric is often used as a very convenient and cheap shock absorber when producing furniture. In containers it is used to protect fragile furniture elements.