All materials from which travel equipment is made consist of fibers. Fibers, in turn, differ from each other in properties, chemical and physical composition, structure, which determines the qualities of the fabrics that allow our equipment to have the properties that we expect from them in a given situation.

The most basic feature on the basis of which all fibers, and, consequently, fabrics are divided, is origin.

There are:

– natural fibers

These include fibers of natural origin (animal, mineral, plant);

– chemical fibers

Their main difference is that the manufacturing process takes place in production. And in turn, chemical fibers include:

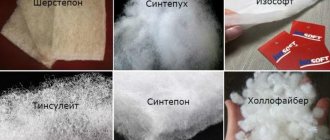

● synthetic . They are obtained as a result of the synthesis of low molecular weight compounds of natural origin (ethylene, methane, phenol and others). A prerequisite is the occurrence of a polymerization reaction (the combination of monomer molecules into large polymer molecules) or polycondensation (the process of synthesizing polymers from polyfunctional compounds). The main raw materials for the production of synthetic fibers are products from the processing of oil, coal or natural gas.

● artificial . Such fibers are obtained from high molecular weight compounds of natural origin, which are formed naturally during the growth of fibers, for example, cellulose, fibroin or keratin. Staple, viscose, acetate, modal are examples of such artificial fabrics. Currently, these fabrics can almost completely replace natural fabrics due to their excellent consumer properties - the material is highly breathable, dries quickly and is tactilely pleasant.

Natural fibers of plant origin

The most common fibers of this origin are linen and cotton. Let's take a closer look at the features of their processing and the process of converting fibers into fabrics.

A. Cotton fibers

These are the fibers on the surface of the seeds of the cotton plant.

After being collected in the fields, the seeds go to cotton gin plants, where they are cleaned of impurities, and then the fibers themselves are separated from the seeds, pressed and packaged.

The cotton fiber itself is a tube with a channel inside. Moreover, the fiber twists several times around its axis.

Cotton fabric is characterized by:

– high strength;

– heat resistance (resistance to high temperatures up to 140 degrees);

– hygroscopicity is about 20%, which is an average;

– a small amount of elastic deformation, which is why cotton products wrinkle quite heavily;

– high resistance to alkalis;

– resistance to abrasion.

Cotton fabrics include taffeta, satin, calico, poplin, chintz, thick flannel, thin cambric, chiffon, and denim. This fabric is often used to make linings for sleeping bags and liners, summer suits for hunting and fishing, and many other products used for outdoor activities.

B. Flax fibers

The source of this fiber is flax stalks.

First, they are soaked so that the microorganisms that appear as a result of this process begin to destroy the tissue of the stems and separate the bast bunches. Then these soaked stems are crushed, ruffled, scratched (yes, this terminology has come to us from ancient times) and is obtained as technical fiber.

What are the characteristics of linen fabrics:

– durable;

– wear-resistant;

– high degree of hygroscopicity;

– dry quickly;

- wrinkles a lot. Therefore, polyester fibers are most often added to linen fabric.

How to determine natural wool and impurities in the composition

If you have doubts about the naturalness of the fabric, you can set fire to several of its threads. Wool without impurities will burn slowly, and the characteristic smell of burnt hair will be felt. The remaining ashes scatter easily.

Material with synthetic impurities will not so much burn as melt, leaving behind small, rather hard droplets.

wool coat

woolen dress

wool cap

wool sweater

Natural fibers of animal origin

These include wool and silk.

A. Wool fibers

Wool is the hair of animals. They mainly use wool from sheep (95%), camels, llamas, alpacas, and goats.

But before wool can be made into fabric, it is subjected to lengthy cleaning, sorting, washing, drying, and only then it is sent to textile production. Sheep wool consists of four types of fibers:

- fluff. It is a very thin, soft, durable fiber.

– transitional hair. This is a thicker fiber compared to down.

– awn. The fibers of this type of wool are coarse and tough.

– dead hair. Because these fibers are punctured by lamellar scales, they become thick, straight and coarse.

Such fabric, for example, as cloth, used in the production of outerwear for hunting, is obtained due to the property of woolen fabric - felting. In addition, it has very low thermal conductivity, which makes it popular in the production of winter equipment.

B. Silk fibers

These are long, thin threads that the silkworm caterpillars secrete to create a cocoon. Silk threads are light and strong - their strength is equal to the strength of steel wire of the same diameter. Silk is hygroscopic and dries quickly.

In travel equipment, silk fabrics are used, for example, in some sleeping bag liners (liners).

Classification

Wool fabric has its own classification. The fabric may differ in production technology, composition and purpose.

Depending on production technology

- Worsted. It has a smooth surface with a clear pattern. It is obtained from twisted combed yarn.

- Thin cloth. It has a fluffy surface that hides the texture of the material. The pile increases the heat-shielding properties, but at the same time it increases the dust holding capacity of the fabric and reduces its resistance to contamination.

- Rough cloth. The material is fleecy, but in appearance it looks heavier, thicker and rougher, since in the process of its production hardware yarn was used with the addition of textile waste. This fabric is highly wear-resistant, but at the same time has little drape.

According to the presence of impurities

- Pure wool fabric. It contains no more than 10% of synthetic fiber impurities.

- Half-woolen fabric. Up to 80% artificial threads are added to the material. They increase wear resistance, reduce shrinkage and wrinkling, but at the same time worsen hygroscopicity and even stiffen the fabric.

By purpose

- Dress fabrics. The thinnest and most easily draped fabrics. Their density ranges from 80-160 g/m2.

- Suit wool. It has an average density (200-400g/m2). It has an excellent fit, softness and wrinkle-resistance.

- Coat coats . They are characterized by high density (350-750 g/m2) and thickness. They are characterized by increased wear resistance and heat protection.

Modern wool processing technologies

Despite the fact that wool is the oldest insulation used by man, the method of producing woolen products has changed little - only technology has improved.

As before, the process begins with cutting or combing the animals. At the next stage, the wool is sorted, washed, pressed into bales and sent to factories. There, on special machines, it is combed and separated into fibers. After combing, the wool is sent to a mixing chamber, where powerful air currents mix fibers of different types of wool to give it the desired characteristics. In the same chamber, wool can also be mixed with synthetic fibers, such as polyester.

After the mixing chamber, the wool goes to the next machine, which is called a carding machine. This machine unravels and separates the fibers into parallel strands and also removes any remaining dirt from them. The wool comes out of the carding machine in the form of a thin, even web, which at the next stage is divided into strips, twisted and transformed into so-called rovings, which already resemble woolen thread. To give the thread the necessary strength, the roving is knotted - stretched and twisted tightly.

Wool yarn is used to knit knitted fabrics, and woolen fabrics are produced from the threads on looms. Knitted woolen fabrics and fabrics are then used to produce various clothing and household items.

High quality wool products are marked with the “Woolmark”, which previously belonged to the International Wool Secretariat. Now the trademark is owned by the Australian Wool Association, Australian Wool Innovation Limited, which is engaged in promoting and increasing global demand for quality wool. The presence of the “Woolmark” label on the product indicates that the fabric contains at least 93% high-quality natural wool and the material is produced in compliance with all standards for the extraction and processing of raw materials.

The leading country in the supply of wool to the world market is Australia. It is followed in descending order by New Zealand, China, the USA, Argentina, Turkey, Iran, Great Britain, India, Sudan and South Africa.

Cellulose

From a chemical point of view, this substance is a polymer, the composition of which is expressed by the formula (C6H5O5)n. The monomeric unit of the chain is beta-glucose. The main places where cellulose is contained are the cell walls of plants. That is why wood is a valuable source of this compound.

Cellulose is a natural polymer that has a linear spatial structure. It is used to produce the following types of products:

- pulp and paper products;

- faux fur;

- different types of artificial fibers;

- cotton;

- plastics;

- smokeless powder;

- films and so on.

It is obvious that its industrial significance is great. In order for this compound to be used in production, it must first be extracted from plants. This is done by long-term cooking of wood in special devices. Further processing, as well as the reagents used for digestion, vary. There are several ways:

- sulfite;

- nitrate;

- soda;

- sulfate.

After this treatment, the product still contains impurities. It is based on lignin and hemicellulose. To get rid of them, the mass is treated with chlorine or alkali.

There are no biological catalysts in the human body that would be able to break down this complex biopolymer. However, some animals (herbivores) have adapted to this. Certain bacteria settle in their stomach and do this for them. In return, microorganisms receive energy for life and a habitat. This form of symbiosis is extremely beneficial for both parties.

Rubber

It is a natural polymer of valuable economic importance. It was first described by Robert Cook, who discovered it on one of his travels. It happened like this. Having landed on an island where natives unknown to him lived, he was hospitably received by them. His attention was attracted by local children who were playing with an unusual object. This spherical body pushed off from the floor and jumped high up, then returned.

Having asked the local population what this toy was made of, Cook learned that this is how the sap of one of the trees, the Hevea, solidifies. Much later it was found out that this is the biopolymer rubber.

The chemical nature of this compound is known - it is isoprene that has undergone natural polymerization. Rubber formula (C5H8)n. Its properties, due to which it is so highly valued, are as follows:

- elasticity;

- wear resistance;

- electrical insulation;

- waterproof.

However, there are also disadvantages. In the cold it becomes brittle and brittle, and in the heat it becomes sticky and viscous. That is why there was a need to synthesize analogues of an artificial or synthetic base. Today, rubbers are widely used for technical and industrial purposes. The most important products based on them:

- rubber;

- ebony.

Polymers: general characteristics

From a chemical point of view, a polymer is considered to be a molecule with a huge molecular weight: from several thousand to millions of units. However, in addition to this characteristic, there are several more by which substances can be classified specifically as natural and synthetic polymers. This:

- constantly repeating monomer units that are connected through various interactions;

- the degree of polymerization (that is, the number of monomers) must be very high, otherwise the compound will be considered an oligomer;

- a certain spatial orientation of the macromolecule;

- a set of important physicochemical properties characteristic only of this group.

In general, a substance of a polymeric nature is quite easy to distinguish from others. One only has to look at its formula to understand this. A typical example is the well-known polyethylene, widely used in everyday life and industry. It is a product of a polymerization reaction involving the unsaturated hydrocarbon ethene or ethylene. The reaction in general form is written as follows:

nCH2=CH2→(-CH-CH-)n, where n is the degree of polymerization of the molecules, indicating how many monomer units are included in its composition.

Also, as an example, we can cite a natural polymer that is well known to everyone, this is starch. In addition, amylopectin, cellulose, chicken protein and many other substances belong to this group of compounds.

Reactions that can result in the formation of macromolecules are of two types:

- polymerization;

- polycondensation

The difference is that in the second case the reaction products are low molecular weight. The structure of a polymer can be different, it depends on the atoms that form it. Linear forms are common, but there are also three-dimensional mesh forms that are very complex.

If we talk about the forces and interactions that hold monomer units together, we can identify several main ones:

- Van Der Waals forces;

- chemical bonds (covalent, ionic);

- Electronostatic interaction.

All polymers cannot be combined into one category, since they have completely different natures, methods of formation and perform different functions. Their properties also differ. Therefore, there is a classification that allows you to divide all representatives of this group of substances into different categories. It may be based on several signs.

Caring for wool products

Caring for items made from natural wool is not difficult, however, they require a special approach and the use of special detergents.

Hand wash and machine wash

When machine washing items made from natural wool, you should select a delicate cycle. Or wash them by hand, and the water temperature should not exceed 300C. In this case, it is necessary to avoid sudden changes in water temperature, which can lead to severe shrinkage of the woolen item. The detergent used for washing must have a special label.

To keep wool items soft and have a pleasant aroma, you can use fabric softener when rinsing.

Tip: Woolen items should not be bleached in chlorine-based solutions. The fabric will darken and become stiff, and its fibers will lose strength.

Drying and ironing

Wring out woolen items by hand and dry them in a horizontal position, laying them out on a towel or sheet. When ironing, select the temperature indicated on the product label.

Storage and use of moth repellents

Woolen items should not be stored in the closet on “hangers”, since in this case the sleeves and shoulders will stretch over time, but on a folded shelf.

When loops and puffs appear, they should be pulled out to the wrong side using a crochet hook or any object with a sharp end. Under no circumstances should the threads be cut or broken.

In areas of intense friction, the fabric may roll. It is best to remove pellets from woolen items using a special machine. However, at home, a simple razor blade is often used for this purpose, which can damage the fibers and cause defects on the canvas.

Amber

It is a natural polymer, since its structure is a resin, its fossil form. The spatial structure is a framework amorphous polymer. It is very flammable and can be ignited with a match flame. Has luminescent properties. This is a very important and valuable quality that is used in jewelry. Amber-based jewelry is very beautiful and in demand.

In addition, this biopolymer is also used for medical purposes. Sandpaper and varnish coatings for various surfaces are also made from it.

Variety of assortment

- Boucle. Loose, thick and heavy fabric with a characteristic knotty texture. When cutting, the edges of the parts crumble, which makes the process quite labor-intensive. Used for sewing suits.

- Velours. Material with thick pile. Suitable for elegant dresses, suits, curtains, furniture covers.

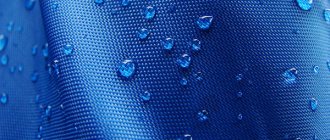

- Gabardine. Thick fabric with small diagonal rib. Repels water well. After special treatment of the threads it becomes waterproof. Used for sewing outerwear and bags.

- Jersey. Very soft knitwear intended for dresses, suits, skirts and demi-season coats.

- Drap . Very thick, dense and heavy coat fabric made of wool with felted pile.

- Jacquard. Suit fabric with fancy convex patterns.

- Crepe. A thin, durable fabric made from tightly twisted threads. Somewhat rough to the touch. It drapes well and is suitable for sewing suits and dresses of any style.

- Reps . Costume-resistant fabric from which school uniforms and office suits are made, since it is characterized by increased resistance to various mechanical influences.

- Tweed. National pride of the Scots. Fabric with a fleecy surface with a small rib. The main feature of the fabric is the presence of colored threads in the weave. Suitable for sewing suits, coats and hats.

- Felt. Non-woven material obtained by felting goat or rabbit down. Used for the production of women's capes, hats, soft shoes and decorative interior items.

- Plaid. Checkered fabric for sewing men's shirts, skirts, dresses and children's clothing.

Starch

The natural polymer starch is a waste product of plants. They produce it through the process of photosynthesis and accumulate it in different parts of the body. Its chemical composition:

- amylopectin;

- amylose;

- alpha glucose.

The spatial structure of starch is very branched and disordered. Thanks to the amylopectin it contains, it is able to swell in water, turning into a so-called paste. This colloidal solution is used in technology and industry. Medicine, the food industry, and the production of wallpaper adhesives are also areas of use of this substance.

Among the plants containing the maximum amount of starch are:

- corn;

- potato;

- rice;

- wheat;

- cassava;

- oats;

- buckwheat;

- bananas;

- sorghum.

Based on this biopolymer, bread is baked, pasta is made, jelly, porridge and other food products are cooked.