Synthetic materials have become a part of our lives. The most common of them are polyamide and polyester, which are included in most purchased clothing. Our appearance and comfort depend on their properties. Let's try to figure out which is better, polyamide or polyester. They cannot be compared with natural and artificial fibers; the strength properties of synthetic materials are much higher.

Types of fabrics

Materials of different properties and qualities are produced in their pure form and with additives. The range of applications is very wide:

- cotton blend underwear;

- warm underwear made from a mixture of natural wool;

- knitted fabric for sportswear;

- a varied range of fabrics from evening silks to summer chiffons;

- voluminous coat fabric with the addition of synthetics is not afraid of weather conditions, is easy to care for and lasts a long time.

Mixed with other fibers and in pure form, synthetics serve modern people well in bad weather conditions.

Comparative characteristics

Traditional summing up: our experts conducted a thorough comparison of the two materials and made a detailed comparison. The result is in the table.

| Polyamide | Polyester | |

| Strength | High | Moderate |

| Moisture resistance | High | Average |

| Life time | Durable | Durable |

| Compatibility with natural fabrics | Rarely combined with natural materials | Excellent contact with natural fibers, resulting in a fabric that is delicate to the touch and has excellent performance characteristics. |

| Breathability | Low | High |

| Price | High | Moderate |

Rate this article |

| Total votes: 0, rating: 0 |

Advantages and disadvantages

By changing its performance properties, synthetics improve the appearance of natural fabrics. With its addition, knitwear does not stretch, and cotton and wool do not wrinkle. The main thing is that its percentage does not exceed 30%.

Comparing polyester and polyamide, which is better for the economy, the first fiber is not only cheaper in primary production. Some of it is produced by recycling waste plastic. This type of production is less harmful to the environment.

Among the few disadvantages: the electrification of things; dense fabrics do not conduct air well, not suitable for hot weather; with a high content, the material is rigid.

Polyester: features, properties, application

Polyester, in fact, is the result of processing petroleum products. The production process of this fabric is represented by several stages:

- Removal of necessary substances from oil;

- Obtaining polystyrene from them;

- Synthesis of polyester from polystyrene;

- Creation of polyester fibers by melting and cooling the polymer;

- Creation of fabric by weaving threads.

Many people, when choosing suitable items, try to give preference to natural materials, unfairly bypassing polyester. In fact, this fabric is not only practical to wear, but also absolutely safe, comfortable to the touch and has a very affordable price. By the way, the presence of the inscription “100% polyester” on the product label does not limit the appearance and properties of the item. Everything depends primarily on the shape of the fibers used in the production of the material, the type of weave, and the chemical composition of the raw materials.

Depending on the manufacturing technology of polyester, wool, viscose, etc. are added to it. The result is fabrics that are completely different from each other, although they are considered polyester. It is for this reason that the material can be thin like lace, dense like natural knitwear, warm like wool or smooth like elastane.

Advantages

- wear resistance – the polyester fiber used to create polyester perfectly “resists” friction, stretching and other loads;

- Non-susceptibility to deformation - polyester practically does not wrinkle even with intense compression;

- Easy to care for – polyester does not require special washing and ironing conditions;

- Variety of textures and colors - polyester can have almost any texture and shade;

- Light weight - most varieties of polyester are very light;

- Good water-repellent properties - this allows you to avoid rapid wetting of the fabric and the appearance of stains on it;

- Affordable price - polyester will cost much less than most natural fabrics;

- Low elasticity - the fabric does not stretch much and retains its original shape perfectly.

Flaws

- Electrification - since we are talking about synthetics, things can accumulate dust and fit too tightly to the skin, creating discomfort;

- Rigidity – which, again, can cause discomfort (that’s why, for example, cotton is added to the composition);

- Allergen - we are talking only about those products in the creation of which the technology was not followed. This is why you should think twice before buying very cheap polyester items;

- Excessive density - due to this property, polyester clothing is not particularly comfortable to wear during hot periods.

Types of polyamide materials

The textile industry uses fiber to mix with natural fibers - wool and cotton, to produce products beloved by girls, such as nylon tights. Considering polyamide and polyester, which is better for outer sportswear, the plastic derivative will be out of competition. Nylon and nylon are obtained from 100% polyamide. Down jackets with such coatings are the best in their range. Nylon windbreakers are used with pleasure by athletes; they are lightweight and windproof; they are included in sports kits from well-known companies. Nylon is a weightless transparent fabric, it is the only one with such properties, and is used in elegant clothing.

Polyamide, polyester, elastane. Understanding synthetic additives

Synthetic additives in yarn for sewing socks are necessary.

Without them, the sock becomes an ordinary piece of fabric that cannot be put on the foot. And the service life of such socks would be limited to a few hours. Also included in the socks, the synthetic material allows them to keep their shape, gives the fabric stretchability and creates a pleasant sensation when in contact with human skin. The manufacturer indicates the composition of the yarn from which the socks are sewn on the product label. There you can see the following names: polyamide (P/A), polyester (P/E), elastane (lycra) . Let's try to figure out what is the difference between these additives and how they change the properties of socks.

Advantages and disadvantages

It is lightweight and durable; these properties are transferred to natural materials in the mixture. 10% polyamide is enough to increase the wear resistance of cotton and wool by 2-3 times. The material is fusible, resists high temperatures, and after cooling retains the shape achieved when hot.

What is better, polyester or polyamide, you evaluate when you use a specific product. Each of the fibers considered is distinguished by its positive properties. Affordable polyester improves properties without increasing the cost of the material. Polyamide in a small percentage greatly changes the properties of natural materials in the underwear range, and hosiery products adorn the legs of modern girls.

Sewing master classes at the school “I Want to Sew”

Reviews

Svetlana Sergeevna, housewife:

I have three children and I often buy outerwear for them. I always look at the composition of the fabric. When buying things with polyamide, I am sure that they are easy to wash and retain their original appearance for a long time. Jackets and trousers for children look very beautiful, but to get them dirty, you need to try very hard. I see polyester most often on underwear labels.

Marina Vitalievna, pensioner:

I have always loved natural fabrics. But recently, this type of material has become expensive and difficult to maintain. For years now I have been buying products containing polyamide or polyester: socks, bed linen, knitted sweaters and more. This helps save money, and is in no way inferior in quality to things made from natural fibers. I don't see any significant difference.

Main Differences

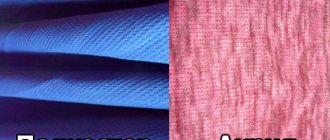

Let's look at the difference between polyester and polyamide. Several points can be noted:

- appearance;

- thickness;

- density;

- purpose.

Both materials are highly durable, wrinkle little, and are resistant to light. At the same time, polyamide is more durable, but less resistant to moisture.

Pros and cons of fibers

To figure out which is better - polyamide or polyester, let's look at the advantages and disadvantages of both materials. First of all, the choice arises when it is necessary to buy outerwear, which should be practical and protect from adverse environmental factors. The differences between polyester and polyamide in outerwear are presented in the table.

| Polyamide | Polyester |

| pros | |

| The clothes look very beautiful and attractive | A huge selection of models - the material can be different: matte, shiny, glossy |

| The service life is very long, and the product will not lose its original attractiveness | Pleasant to the touch |

| An abundance of textures, from glossy to matte | It is distinguished by its strength and durability, while not losing its original attractiveness |

| A large number of color options | Keeps its shape well |

| Wear resistance | Doesn't wrinkle |

| Outerwear provides good protection from the wind | Will not fade in the sun |

| Does not allow water to pass through and repels dirt | |

| Easy to care for, such clothes will not fade when washed. | |

| Dries quickly | |

| Minuses | |

| Doesn't retain heat well | The products are quite tough |

| Generates static electricity | The fabric does not allow air to pass through well and prevents skin breathing |

| Becomes tough when exposed to high temperatures | Accumulates static electricity |

| It is very difficult to remove greasy stains from such fabric. | |

| Does not absorb moisture | |

The table shows that each of the materials has both advantages and disadvantages.

For outerwear in winter, it is better to choose products containing polyester. And for the warm season, the best option would be things made of polyamide.

Polyamide differs from polyester in its longer service life and wear resistance; clothing made from such material can last for many years without losing its visual appeal.

This is interesting: Poplin or satin - which is better, the difference in materials in composition, weight, use

Polyurethane (PU) based coatings

Polyurethane has greater strength, rigidity, and color fastness. In most cases, it is applied in a layer of 50 microns after preliminary galvanizing and priming of the steel. It is a high-quality and reliable solution. Can be matte or glossy.

Pural and Pural matt. Protective compounds with improved properties developed by the Finnish concern Ruukki. The base is polyurethane modified with polyamide granules. Polyamide granules further increase the rigidity and strength of the polymer composition. At the same time, it remains elastic and resistant to peeling. Visually it differs from polyester in its slightly rough surface. Pural and Pural matt includes not only a polymer, but also a passivating layer of zinc and an adhesion-increasing primer. The composition and application technology are patented by Ruukki.

Quarzit and Quarzit Matt. Textured polyurethane with matte or glossy surface. Used for Grand Line metal tiles. Aluzinc 265 g/m2 is used to passivate steel. The polymer layer is applied with a thickness of 50 microns. It is resistant to mechanical stress and does not fade under the rays of the sun. Quarzit Lite is also available - thickness 25 microns, price reduced

Steel cashmere. Presented in the Stynergy line, produced by the Severstal concern. The composition contains polyurethane modified with polyamide granules, applied in a layer of 50 microns after galvanizing steel 275 g/m2. A special feature of “Steel Cashmere” is an additional conversion coating that protects zinc in case of damage to the polymer surface.

Puretan. Developed by AkzoNobel, glossy surface. The composition contains polyurethane, polyamide granules are used for texturing. The thickness of the polymer coating is 35 microns.

Can be matte or glossy. It has high color fastness and resistance to mechanical damage. Contains polyvinyl fluoride (80%) with the addition of acrylic (20%). The coating was developed by the Ruukki concern. The technology of its application involves galvanizing steel 275 g/m2. Thickness - 27 microns, surface can be textured or smooth. PVDF and PVDF matt are used for facade materials; they are rarely applied to metal tiles.

Fiber synthesis

The combination of polyester and polyamide results in elastic, wear-resistant fabrics that maintain a presentable appearance for a long time. This synthesis is optimal for the manufacture of women's underwear. “Diluted” polyester does not absorb moisture so much and is almost unable to become electrified.

Polyester also goes well with elastane (soft film). This "mixing" is widely used to create hosiery, sportswear, gloves and fitted knits. Thanks to elastane fibers, the material becomes “breathable” and has good “ductility”. However, items made through such synthesis may fade and turn yellow when exposed to direct sunlight.

The combination of cotton with polyester (no more than 35% of the latter) makes the fabric more durable. Also, clothes made from cotton with the addition of synthetic fibers do not stretch and do not fade in the sun.

There is an opinion that synthetic fabrics can cause allergic reactions. However, this opinion is erroneous. The only thing that can result from wearing clothes that contain synthetic fibers (polyamide/polyester) is a slight feeling of discomfort upon contact with the skin in individual cases.

For information on the difference between polyurethane and polyester, see below.

What is nylon?

In the textile industry, this term refers to synthetic fabric, the production of which uses polyamide raw materials. When adipic acid interacts with hexamethylenediamine, a chemical reaction occurs, resulting in the formation of salts. Solvents are added to this composition. After heating the resulting solution, polyamide is formed - a special type of plastic from which the fibers used in the manufacture of nylon fabric are made.

The advantages of nylon include:

- strength;

- ease;

- wear resistance;

- softness;

- resistance to chemicals, fungus and mold;

- dimensional stability;

- smooth texture;

- ability to dry quickly;

- low creasing;

- elasticity;

- ease of care.

The disadvantages of this fabric are:

- low color fastness;

- airtightness;

- tendency to accumulate static electricity;

- low hypoallergenicity.

Manufacturers

Today the following polyamide manufacturers are known:

- DiEv LLC. The work of this enterprise began in 1994. At first, its specialization was related to the production of cornices, but after some time the plant diversified its products and began to produce synthetic fibers.

- JSC "Chernigovskoe KHIMVOLOKNO". This plant is the leading chemical enterprise in Ukraine.

- LLC "Kedron-Perm" This company began producing its first products in 2000. Today its main focus is the production and supply of products based on fluoroplastic and polyamide.

- Sofinova LLC is a Ukrainian company founded in 2009. It is one of the components of the French group SOFIMECA, which specializes in the production of synthetic fibers.

- JSC "Grodno Khimvolokno" This large enterprise is located in Belarus. The plant produces polyamide fibers, threads, cordon fabric and polymer materials from polyamide-6.

- JSC METAFRAX is a chemical plant operating in Russia. The company is the largest manufacturer of methanol and its derivatives.

Structure and production of polymer coated steel sheet

A protective layer of polymer materials is usually applied to rolled steel. It is problematic to evenly distribute the substance on finished profiled products. Only expensive equipment can solve this problem, which has a very negative impact on the cost of production.

Attention! For the manufacture of profiled products, high-tech automated lines are used, since the protective coating is quite thin and can be easily damaged when using primitive machines.

Steel sheet coated with polymer materials has a complex structure and is produced in several stages:

- The basic protection against corrosion processes in these products is the zinc layer.

- At the passivation stage, zinc is covered with a corrosion barrier - an oxide film.

- Primer – increases the adhesion of the base layer and polymer protector.

- As a finishing coating for the front side of the sheet, a polymer is used, protected for the period of storage and transportation by self-adhesive film. A special varnish is usually applied to the inside.

There are several ways to apply a polymer layer, the most common is powder. The essence of the process is that an electric current is passed through a product placed in a special chamber, and a fine powder with an electric charge of opposite sign is sprayed. Under the influence of an electromagnetic field, polymer particles adhere tightly to the metal surface. The painted sheet is sent to the oven, where the outer layer is polymerized.

The use of powder coating has a number of advantages compared to the process using liquid compositions:

- The dye is distributed evenly, with minimal error. The defect rate is insignificant.

- The polymer-powder layer has high adhesion to the base surface.

- The strength of the coating ensures its resistance to mechanical damage and, therefore, a long service life.

Let's look at the most popular types of polymers used to coat galvanized steel.

Elastane

There may be other names for this synthetic additive - lycra and spandex. Lycra is a proprietary name.

This is a very popular material in the production of socks due to the following properties:

Elasticity. Socks with elastane have good stretch, and after stretching, they quickly and easily return to their original shape.

Strength and wear resistance. The addition of elastane doubles the service life of socks.

Density. This creates a stretch effect: socks with elastane hug the leg beautifully.

Breathability. The skin of the feet “breathes”.

Comfort. The socks are pleasant to the touch, do not wrinkle or shrink.

Elastane doesn't have many disadvantages. You may note intolerance to prolonged exposure to direct sunlight. In rare cases, it may cause allergies.

Care instructions:

Preferably hand wash at room temperature, machine wash only in gentle mode;

light spin only;

do not use air conditioning;

dry away from sunlight, preferably in a horizontal position.

Now you are armed with the necessary knowledge and can consciously make a choice on our website of the appropriate sock model.

Polyurethane: the most important advantages

First of all , the difference between polyester and polyurethane lies in a number of important quality characteristics - in favor of polyurethane . Polymer polyurethane coating:

- much more elastic - cracking for any reason in the polymer layer of metal tiles is practically eliminated;

- high level of adhesion - the polyurethane surface coating is more durable;

- enviable durability - corrugated sheets or metal tiles with a polyurethane layer have a long service life, during which the product does not lose its appearance.

These are just some of the most notable benefits of polyurethane coatings. Based on this, you can easily distinguish a roofing material made of polyester from a sheet that looks exactly the same, but only has a polyurethane coating. To do this, just try to scratch the unnecessary piece of sheet a little - of course, without fanaticism, without putting in much effort. The polyurethane coating is only slightly deformed, but the polyester coating can scratch to the metal with the same effort.

However, in many cases, consumers choose corrugated sheets with a polyester polymer coating, since the price of such a roofing product is more affordable. If care is taken during transportation and careful installation, the service life of such material is also significant. True, large dry branches that fell on the roof during a storm can leave noticeable marks on the product, but this is a completely different question.

Selecting the optimal coating depending on environmental conditions

| Environmental conditions | Roof | Facade | |

| Middle strip, clean non-industrial area, surface does not require frequent maintenance | Polyester – glossy and matte, pural and plastisol | Polyester – glossy and matte, pural and plastisol | |

| The area is located near busy highways, the surface requires care - washing, cleaning | Polyester, pural and plastisol | Pural and plastisol | |

| Industrial area with polluted air | Pural, plastisol, PVDF | Pural, plastisol, PVDF | |

| Southern regions with active ultraviolet radiation | Pural, PVDF | Pural, PVDF | |

| Area with a maritime climate | Plastisol (if the climate is not too hot), pural, PVDF | Plastisol, pural, PVDF | |

| Regions with cold climates | Plastisol, pural, PVDF | Plastisol, pural, PVDF | |