To get a beautiful, even stitch on things, you need to take into account many factors. One of them is a competent choice of threads. If they do not correspond to the type of material or needle size, the stitches will be uneven, ugly, or missing completely.

Sometimes the thread simply breaks, which suggests a malfunction of the equipment, but more often the reason is the wrong choice. What factors should you pay attention to when selecting? What types are they presented in?

Types of threads and nuances of operation

Each sewing machine comes with instructions that indicate how to use a certain type of thread depending on the material. Sewing products are represented by the following types:

Cotton

A universal solution that goes well with handmade work, which is important both when sewing a new item and when restoring an old one.

They are in demand both among sewing masters and beginners. Cotton products are inexpensive and suitable for any material.

A universal solution is size 50, but if the fabric is too thin, tears and holes in the stitch area are likely.

With a high density of the material being processed, on the contrary, the strength may be too low, which can lead to ruptures.

Polyester

Synthetics ensure a beautiful, even stitch. Due to the smoothness of the fibers, there are no roughnesses in the stitch area that are characteristic of other materials. The threads are elastic and can withstand some tension without causing even minimal damage.

A modified solution is a polyester thread in a cotton sheath, combining the advantages of both options.

Reinforced

The special structure of the fibers ensures maximum elasticity and resistance to mechanical stress. Domestic marking is determined by the type of material.

LH - cotton-based thread, LL - flax, LS - wool. Thickness is also indicated; the higher the number, the thinner the product.

Nylon

They withstand contact with water, including long-term contact, and are characterized by fairly high rigidity, and therefore are used in the production of shoes, bags and other accessories subject to high loads. In clothing, nylon threads can be used for hidden stitches. The thread is formed from one fiber, or from several, the structure affects the strength.

Silk

Contrary to popular belief, it is permissible to use silk threads not only with fabrics made from similar raw materials or wool, but also with others. They are quite expensive, but are characterized by color fastness and do not fade with regular ironing or high-temperature washing.

The main point is to choose the correct size and focus on the structure of the material being sewn.

Special types of threads are used to decorate clothes and form unusual embroideries and patterns. Special threads with metallized fibers and impregnations with compounds capable of accumulating and emitting light are also suitable for these purposes.

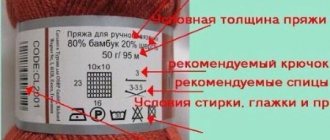

Marking features

To understand the marking, you need to consider that threads can be natural, mixed, or synthetic.

For example, the classification of natural threads is as follows:

- Cotton (cotton). In their pure form, they are rarely used, as they lack strength and wear resistance. Their area of application is sewing clothes that must meet the most stringent requirements for hygiene and safety, for example, baby undershirts, diapers;

- Silk (c), viscose (c) - mainly used for decorative purposes, in needlework, embroidery;

- Linen (marking varies depending on the manufacturer and country of manufacture) - used when working with heavy, high-density fabrics, for example, tarpaulin for backpacks and travel bags.

Synthetic and combined threads are presented in the following categories:

- Reinforced (LH, LL, LS) - the most durable and universal. The thickness is different, varies from 36 to 80, so you can choose a solution for sewing clothes from thin fabric, and for making shoes from thick leather, specialized textiles;

- Polyester threads, including staple threads (L, LSh). The products withstand contact with moisture, are elastic and very durable. Staple threads are used for sewing knitwear, thick polyester threads are used for shoes, bags, leather accessories;

- Polyester textured (PT). The most common solution for sewing knitwear, they are cheap, elastic and durable;

- Polyamide (K). They are used infrequently, can withstand prolonged contact with moisture, but, unfortunately, are afraid of temperature fluctuations.

Foreign brands actively use metric numbering, in which the first number indicates the number of meters of thread in its gram. A number separated by a fraction indicates addition. Also, foreign brands fix the direction of twist: s – left, z – right.

The number of folds affects the quality; the more, the better.

Additional recommendations

Keep in mind that synthetic yarn is a good choice. Sometimes it is no worse, or even better than natural. The prickliness of the product will be less if it is knitted not from pure wool, but with an admixture of synthetic fibers. So it is better to choose mixed materials.

To avoid the appearance of pilling on the finished product, it is recommended to use knitted yarn marked “anti-pilling” for knitting, and also wear the knitted item carefully, minimizing friction.

It is better to keep the label from the yarn until the end of knitting: if the threads unexpectedly run out, you need to pick up the same ones, preferably they are from the same batch.

It is recommended to wash knitted items in lukewarm water using a mild detergent. Dry only in a horizontal position, do not hang (the product will deform under its own weight).

Principles for selecting threads based on shade, shine, and fabric quality

The listed indicators are of greatest importance during selection. In addition, the fibers must be uniform; this indicator can be assessed by examining the threads on fabric of a contrasting tone. The main quality parameter is a smooth structure with no compactions or knots. Strength can be determined by tension; at its average value, ruptures are unacceptable.

You can choose the thickness of the thread according to the type of product being manufactured and the characteristics of the fabric:

Children's clothes, knitwear, products based on natural cotton. The best option is standard size 40 cotton threads.

Light items made of chiffon, tulle. The best solution is a 70-80 size reel.

Thick fabric used for tailoring suits is processed with 50-70 threads.

Thin products made from dressed wool, satin, and synthetics look great when processed with threads with a thickness of 40 to 70.

For heavy, dense fabrics (such as tarpaulin), artificial, natural leather, strong threads of 30-40 are used.

Silk threads are the most versatile, therefore, there are essentially no restrictions on compatible fabrics.

Classification by finishing features

According to the type of finish, the following materials can be distinguished:

- Matte (feature: complete lack of shine, maximum light absorption);

- Glossy (characterized by shine, making the item more unusual);

- Harsh (made from a material that cannot be cleaned or bleached);

- Standard plain, colored, white or black threads;

- “Smoking” type threads. They are needed to create a gathered effect on the fabric. When treated with heat, they form shrinkage, the stitching tightens, taking the base material with it. The relief features are determined by the type of seam and the structure of the material;

- Threads with special processing that gives them certain properties. For example, this category includes materials treated with a reflective substance or a composition that ensures the ability to withstand open fire.

Quality checking

To purchase a truly high-quality thread, you need to be guided by several points:

It is better to focus on products from trusted brands that are respected by experienced seamstresses.

Unnamed Chinese goods are cheap, however, the markings on the spool do not always correspond to reality; there is a high probability that, for example, the reinforced threads will contain cheaper, low-quality fibers that are not strong enough for sewing some things.

You need to unwind the spool a little and inspect the thread. A high-quality product is smooth to the touch, its thickness is uniform along the entire length, there are no lumps or excessively thin areas. If this condition is not met, then tears will form in thin places, and folds of fabric will form in thick places.

Unfortunately, defects cannot always be seen with the naked eye, and in this case even minimal deviations are important. To avoid mistakes, you need to conduct an inspection using a magnifying glass.

You should also check the uniformity of the shade. If the color is the same along the entire length, this means that the manufacturer strictly adheres to production technology.

Any deviations are clearly visible against a contrasting background. For example, the quality of black thread can be easily checked against the background of contrasting white fabric.

The thread needs to be tightened a little. Any thread has a small reserve of elasticity if it is of high quality, regardless of the material. The rupture will follow only after some tension has been felt.

Expert opinion

Maria Anishchenko

Experienced seamstress, total experience 18 years

Practice shows that threads made from natural raw materials, be it cotton or linen, need to be checked most carefully. Synthetics are cheaper, easier to produce, and do not require the manufacturer to use expensive machines and equipment. Low-quality synthetic threads are very rare.

Quite often there are old threads on the farm that are already 2-3 decades old. Thrifty housewives are trying to use them in business, but this is a wrong decision.

The thread seems to be a very simple product, however, if the temperature and other storage conditions are not observed, the material is destroyed and the structure loses its uniformity.

This affects not only the quality of sewing, but can also damage the mechanisms of modern sewing machines. Even a small knot will lead to jamming; you will have to stop work and carefully remove the material from the work area.

Synthetic yarn

This group includes yarn that is obtained entirely artificially from chemical materials, such as acrylic, polyamide, nylon, nitron, polyester, elastane and other types of fibers. Synthetic fibers are used as a replacement for natural fibers to reduce the cost of yarn. They are also used as an additive for natural fibers to improve the properties of natural fibers, for example, to increase strength, elasticity, shine and other properties.

Synthetic fibers are low-hygroscopic and highly electrified, but in contrast to these disadvantages there are also advantages: they are very elastic, durable and wrinkle little.

Correspondence table for material, needle numbers and thread markings

| Material | Type of thread | Needle number |

| Lightweight fabrics. Finished cotton fabrics of minimal thickness, artificial and natural silks, synthetics, knitwear | Cotton threads thickness from 80 to 100, polyester - from 60 to 80, nylon - from 80 to 100 | 9-11 with thread thickness from 70 to 80 |

| Medium weight fabrics. Cotton fabric, satin, canvas, wool, which has undergone appropriate processing. | Cotton threads thickness from 50 to 80, polyester - 50, nylon - 50-80 | 11-14 |

| Heavy fabrics. High-density wool, specialized reinforced tarpaulin, aimed at making bags, tourist clothing, protective suits, fabric for sewing curtains, thick jeans. | Cotton threads – 40-50, polyester – 50, nylon – 50-60 | 14-16 |

| Elastic materials, e.g. double jersey, special fabrics for sports overalls. | Polyester – 50-80, nylon 50 | 11-14. It is better to use special needles designed specifically for working with synthetic fabrics. |

How are threads marked?

Each reel is sold with a product number. Threads are marked with numbers from 10 to 100. The highest number of the product number indicates the thinnest thread . For example, outerwear is sewn with thread No. 20, and a light cotton dress will be sewn with No. 40 or 50.

Reinforced threads are also marked:

- LL – where the first L means that the core is polyester fiber, and the second L is a lavsan (polyester staple) braid;

- LS – silicone braid;

- LH – cotton braid.

Experts believe that the best threads in terms of their sewing qualities are those that are marked with the abbreviation LL. They combine the best qualities of artificial fibers, enhanced by the reinforcement process.