High strength, resistance to temperature changes and low cost explain the widespread use of polypropylene fabric. It is used in agriculture, road construction, production of outerwear and footwear, medicine, construction work, and furniture manufacturing. In this article we will tell you what polypropylene fabric is, what its varieties are and where it is used.

Varieties and properties

Traditionally, the raw material for burlap was thick and durable fibers from plant materials, depending on which it can have a gray, brownish or yellowish tint . Modern fabric can also be synthetic. The main types of raw materials for this material, which is produced using the plain weave method, are:

- Hemp (hemp). This is the most durable fabric that does not rot and withstands repeated washing at high temperatures.

- Linen. This type of burlap, which is the most common, is made from the inner bast fibers of the flax stalk. Linen bags are used primarily for bulk food products, as well as finely divided building materials. They are strong, durable, and wash well.

- Jute. From the fibers of jute, which grows in India, a strong and coarse fabric of a light shade is obtained, which does not absorb water well, does not rot and can withstand temperatures of up to 300 degrees.

- Kenaf, or Bombay hemp. The raw material for such burlap is fiber from a plant growing in the tropics; this coarse, durable fabric is manufactured abroad.

- Polypropylene is a modern packaging fabric based on polymer fibers.

This material can also be made from a mixture of different fibers. The main properties of all types of burlap are:

- resistance to tearing and abrasion;

- breathability;

- chemical resistance and inertness;

- insect resistance;

- low cost.

Natural burlap fabric is also environmentally friendly. Flax and hemp also have high hygroscopicity, which, depending on the purpose of the material, can be both an advantage and a disadvantage.

GOST polypropylene bags. Raw materials, material.

Polypropylene bags are suitable for transporting sugar, flour, cereals, construction materials and other bulk products. On the Russian market they have established themselves as reliable and economical packaging.

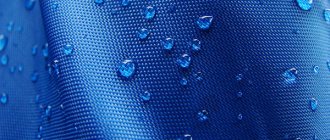

Polypropylene bags have technical characteristics that are much superior to rope, linen and paper packaging. The products are white in color, made from primary processed raw materials and are positioned as one of the most reliable developments. The packaging is made of synthetic fabric with a density of 45 - 100 g/m2. They are traditionally in high demand on the Russian packaging products market.

There are also products made from used raw materials. Such bags are green or gray in color and they cost much less than their white counterparts made from primary raw materials. Mainly used for transporting construction waste.

GOST bags can be equipped with universal liners that protect the contents from high humidity.

Woven polypropylene bags GOST

Woven polypropylene bags GOST are popular among regular customers because:

- Increased impact and mechanical strength;

- Increased resistance to deformation;

- Increased resistance to the action of alkaline salts;

- Immunity to sub-zero temperatures (down to -70C);

- Immunity to positive temperatures (up to +100C);

- Resistance to organic solvents;

- Not susceptible to erosion;

- Resistance to decomposition under unfavorable storage conditions;

- Light packaging weight, high product hygiene.

Material for woven polypropylene bags

Woven raw materials with a density of 40-100 g/sq.m - material for polypropylene bags manufactured in accordance with GOST. Their load capacity is in the range of 25 - 90 kg. Products made from synthetic fibers have the necessary certificates of the State Sanitary and Epidemiological Supervision of the Russian Federation.

Polypropylene packaging is divided into:

- Woven products without lamination;

- Products with lamination;

- Bags with liner;

It is also possible to use similar materials, the technical characteristics of which can provide an increased shelf life of the necessary goods.

Raw materials for woven polypropylene bags

The main raw material is polypropylene threads. They are sewn according to the regulations of the sanitary and epidemiological services.

Polypropylene packaging is indispensable:

- When cleaning gardening facilities;

- In hotels and hotels, in the work of city utilities.

Russian offers reliable polypropylene packaging in various price categories. Call multi-channel phones: +7 (499) 517-91-88, +7 (495) 410-23-58.

Areas of use

The traditional area of use for burlap is transportation, so the requirements for its characteristics are standardized. The standard quality of domestic material depends on its purpose and is determined by the requirements of GOST 5530-2004. The density of burlap can take values in the range of 180-400 g per square meter, and its width can be 110, 106, less often 95 cm.

The most extensive area of application for various types of burlap is the transportation and storage of various bulk cargoes, primarily food and agricultural products (with the exception of finely dispersed ones). Such packaging is reusable, environmentally friendly and reliable, but does not protect the contents from moisture, moreover, it is itself susceptible to rotting. Therefore, its use is allowed only under conditions of sufficient air exchange and the absence of excess moisture.

At the same time, hygroscopicity makes inexpensive, durable and natural burlap a common textile for cleaning, especially in technical buildings, as well as for the primary purification of various liquids. Burlap fabric is also widely used in construction. It is used as a leveling and absorbent pad when painting walls, ceilings, and floors, as well as shock-absorbing and noise insulation. In gardening, vegetable gardening and landscape design, burlap is used to cover plantings, lawns, and protect the root zone. In these cases, it is preferable to use varieties of material with less hygroscopicity.

A common use for burlap is in the manufacture of furniture and mattresses. Thanks to its dim background and uniform structure, against which bright objects stand out well, it is also used in the design of premises, especially creative studios and exhibitions, in theatrical productions, as well as for the creation of clothing and various accessories, especially bags, in an ethnic style. Thin linen burlap is often used for their work by artists, needlewomen and craftsmen.

Characteristics, properties and features of polypropylene fabric

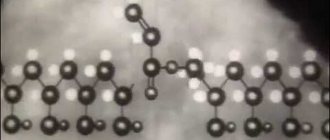

Polypropylene (PP) fabric is a polymer material obtained by weaving polypropylene threads on weaving machines.

Polypropylene fabric is characterized by low fiber density. A unit of raw material yields more fibers than any other material of synthetic origin (1 kilogram of raw materials produces 250 km of thread).

Woven polypropylene and fabrics made from it are leaders in many production areas.

Production process

The manufacturing process includes 5 main stages.

Processing and drying of raw materials . Various dyes and additives (for example, calcium carbonate) are added to polypropylene granules. It paints the canvas white and gives it the necessary rigidity. Next, the mixture is fed into a polypropylene extruder with a flat slot-shaped nozzle and heated to 260 degrees. At this temperature, future bags are dried.

Thread cutting . The hot mixture passes through the nozzle in the form of a thin film. After cooling, it is cut into flat thin threads, which are hardened, drawn and wound on special spools.

Fabric making, cutting . The weaving machine is adjusted to certain parameters: the weave density, the width of the knots, etc. are set. The machine produces a polypropylene sleeve, which is subsequently wound onto large bobbins. They produce polypropylene fabric, which is cut into blanks using the hot cutting method.

Technological process

Print print . A flexographic machine is used to apply images to fabric. The design on the bags can be either polychrome or black and white. Most often, the image is the logo of the production itself or is made to order.

Cutting, bag sewing, packaging . A special machine from the bottom bends the polypropylene fabric a certain number of times and stitches it with thread. The upper part can be either raw or stitched. The finished products are packaged and pressed. The standard pack size is 500 or 1000 pieces. The packages are tightly tied with twine and sent to the warehouse.

Business Features

The production of polypropylene bags is a worthy and promising business. Its owner makes money from recycled materials: this is what people throw away every day. Thus, ordinary garbage is turned into useful things. Polypropylene bags are used as containers for transporting products/goods: cereals, sugar, building materials, sand, etc.

Nuances associated with this business:

- minimal expenses on raw materials or there may be none at all;

- finished products do not require special storage space - they do not deteriorate over time, withstand sudden temperature changes, are not eaten by insects, etc.;

- due to the low cost of raw materials, the final income from business activities exceeds 30-40%;

- opening a business will require a lot of documents and permits, since industrial processing is always controlled by the state;

- the production facility should be located far from residential areas, since recycling plastic and other waste leads to environmental pollution;

- in addition to the main expenses for direct production, an entrepreneur should be prepared to pay various state duties, registration of individual entrepreneurs, expenses for documentation, etc.

To collect the necessary documents, you should contact a lawyer to avoid fines in the future.

Bag warehouse

Where to get raw materials

A cheap option is recycling. But you will have to obtain permission to operate, because... mentioned above - it affects the environment.

A more expensive but safer option is virgin polypropylene. These are small capsules that were once waste but are now recycled and compressed.

Whatever option you choose, you should remember that the market and laws are constantly changing, and you will always have to adapt to them in order to get a decent profit.

What kind of room do you need?

The premises and territory should be immediately taken to a larger size, since the production of bags is profitable, and in a few months expansion will be required. The main equipment is intended not only for the production of bags, but also for other types of packaging. For example, plumbing engineering.

The entire production area is divided into sectors:

- department for the production of polypropylene thread;

- weaving workshop;

- cutting shop;

- office;

- warehouse for raw materials and finished products;

- rest area and locker room for staff.

The premises must be equipped with water supply, ventilation, heating system, sewerage system and located within transport accessibility. A small parking lot for company cars is not required, but is desirable. The budget for vehicles for transporting raw materials and products is approximately 700-900 thousand rubles. It is more profitable to take out a car loan or lease.

It is cheaper to rent a ready-made premises than to rebuild your own. Rent, depending on the region, will be around 200-250 thousand rubles.

How many staff do you need?

The more modern the equipment, the less the number of personnel. For a standard line you need:

- 3-5 loaders;

- 4-5 drivers;

- 15-20 people per workshop;

- 8 people for manual processing;

- manager;

- manager;

- lawyer;

- accountant.

Salary can be either negotiable or regional average. Everything will depend on how quickly the business pays off and how much profit it brings. An entrepreneur should remember that working conditions in the production of polypropylene bags are difficult - high temperatures, paint fumes, noise, etc. Decent salaries and bonuses are welcome.

Bag production workshop