Synthetic padding: reviews, description with photos, we’ll tell you how to wash it, what’s the difference from padding polyester and holofiber, what temperature it is at. As can be understood from the name of the material, synthetic down is synthetic or artificial down. Its properties are very similar to natural goose down, and its performance characteristics are significantly superior to it. Synthetic fluff, as confirmed by reviews and photos, looks like a fluffy mass similar to padding polyester, but the production technology of these two fillers has nothing in common.

Description and structure of synthetic down

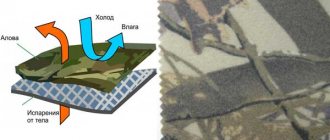

Among other artificial materials, synthetic fluff stands out for its special softness and airiness. It consists of many very fine polyester fibers. Each hair, despite its minimal thickness, has an internal void or cavity. Therefore, the fabric produced is voluminous and light at the same time. The surface of the artificial down fibers is smooth, with a silicone film applied on top.

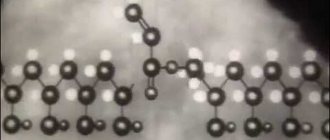

During the production process, the fibers are twisted into a spiral or ball shape.

Important! No glue or other chemicals are used in the production of synthetic fluff.

Varieties

Based on linear density, the following types of synthetic fluff are distinguished:

- fiber length (32 or 64 mm);

- thickness (7 D or 15 D).

Varieties of hardness:

- Soft (7D/32) - is versatile, soft, and retains its shape.

- Hard (15D/64) – characterized by increased elasticity, quickly recovers after load, not intended for stuffing small products.

- Cotton wool - resembles cotton in appearance, is lightweight, has low density, fluffy structure, and low strength.

- Balls - made in soft and hard forms, the balls are formed due to dense twisting during carding, due to this elasticity and excellent shape retention are achieved.

Properties of artificial filler

Thanks to its structure, the material has received the following valuable qualities:

- Lightness caused by numerous air bubbles that fill the space between the fibers. The voids in the fibers themselves give the material additional airiness and weightlessness.

- Low hygroscopicity created by cavities in the fibers. Their sizes are so small that drops of moisture cannot penetrate inside. The outer walls of the fibers do not get wet either, because they are protected by silicone.

- Fibers twisted into spirals or balls have spring properties. When squeezed, they quickly expand and retain their original shape.

Synthetic fluff or holofiber - which is better?

Synthetic down is a non-woven material made by twisting hollow polyester fibers into spirals. Thanks to subsequent processing with silicone, the fibers remain smooth and do not stick to each other, which allows the unique properties of the material to be preserved.

Holofiber consists of a million hollow fibers collected into small balls (lumps). These two materials belong to types of padding polyester, but differ from it in the peculiarities of fiber formation. If synthetic down is produced in production by combing out polyester fiber, then to obtain holofiber it is thermally bonded.

It is very difficult to choose which is better of these two materials, since in terms of heat-regulating properties they are almost identical. But holofiber is more versatile, since it can also be used as insulation in construction, and not only when sewing clothes, blankets, pillows, etc.

You can learn more about the holofiber material and the features of caring for it from a special article.

Advantages of synthetic filler

The properties of the fibers allowed the fabric to occupy a leading position among a variety of insulation and fillers.

Advantages of the material:

- Air layers provide high thermal insulation of the material, so things with synthetic down are very warm and protect well from low temperatures. At the same time, they allow the filler to “breathe”. This breathability ensures comfortable thermoregulation for the body.

- The silicone layer on the threads gives the artificial material all the properties of goose down. Synthetic down is a water-repellent material, thanks to this, things with it are difficult to get wet.

- The fibers also do not accumulate static electricity and do not retain odors.

- The elasticity of fibers is an important quality for clothing. The insulation in it does not crumple or get knocked down, things do not stretch, but retain their shape well when used.

Important! Wet clothes and other items with synthetic down dry faster than items with other fillings.

Synthetic padding and synthetic padding: what's the difference?

Heat-regulating properties are not the main thing that distinguishes padding polyester from synthetic down. The properties of the latter material have been significantly improved:

- artificial down is absolutely non-toxic, unlike adhesive padding polyester, which can be harmful to the body;

- has a longer service life;

- has good breathability and allows products made from it to “breathe”;

- retains thermal conductivity properties even when wet;

- resistant to deformation in any condition;

- does not absorb odors;

- does not crumple when washing.

You can learn more about the properties of padding polyester from another article.

Safety level of synthetic fur

Synthetic fluff is absolutely safe and suitable for almost everyone: the material does not cause allergic reactions.

In addition to being hypoallergenic, it has another quality that is important for human health - it does not collect dust. The structure and properties of the fibers do not allow dust to accumulate, so conditions favorable for dust mites do not arise.

Important! Using items with synthetic down filling will not cause complications in patients with bronchial asthma and other pulmonary diseases.

Composition and appearance of the material

The insulation is a non-woven material consisting of thin polyester fibers, each of which has microscopic holes through which dust and moisture do not pass. But air penetrates through them deep into the villi, which ensures heat retention. Plus fills the space between them, creating additional layers, which increases the heat-saving properties of synthetic down.

The fibers are additionally treated with silicone and then tightly twisted. The shape in the form of a spring (or spiral) ensures strong adhesion of the fibers without the use of adhesive. Thanks to the strong connection, the material is characterized by high strength and elasticity. It does not bunch up and is not subject to shrinkage.

There is also synthetic fluff in the form of soft balls. The structure of the material is more resistant to clumping and stalling.

Fact! The material looks like waterfowl down. This similarity served as the basis for the name. Synthetic fluff is considered one of the best analogues of natural material.

Use of synthetic down

The qualities of synthetic down have made it a material that is used very widely.

Cloth

Winter clothes with artificial down are very warm and light. It holds its shape well and does not restrict movement, so it is convenient for outdoor activities and sports.

Bed dress

Blankets, pillows, and mattresses with such contents are practical and create conditions for healthy sleep and comfortable rest. The properties of the material are especially appreciated by tourists, for whom a lightweight synthetic down sleeping bag reliably protects them from the cold.

Furniture

A special type of synthetic fluff (compacted) is used in the manufacture of upholstered furniture. The elastic material copes well with the functions of the filler; its low cost is important, this makes the products inexpensive for the buyer.

Toys

Synthetic fluff turned out to be very convenient for filling bulky children's toys. Even a child can easily move them, they do not cause injury, and are pleasant to the touch.

Needlework

Handicraftsmen also loved the lush and elastic filler. They use it to make small thought pillows, pincushions, and also to fill homemade dolls.

Area of application of synthetic fluff

Toys - the area of application of synthetic down

All of the listed qualities of synthetic down allow it to be used in the production of winter and demi-season clothing, pillows and blankets, and toys. Denser synthetic fluff is used in the manufacture of upholstered furniture, mattresses and travel equipment. The low cost and availability of artificial filler makes it indispensable for home handicrafts. Embroidered cushions for the sofa, fashionable patchwork blankets, homemade toys - synthetic down is required everywhere.

Rules for caring for synthetic fluff

The artificial filler is easy to use and does not require special care.

Following simple rules will extend the life of use and preserve the quality of the material.

Wash

The products can be washed either by hand or in the drum of a washing machine. Acceptable washing mode: delicate.

Important! You can wash things in hot water, maximum temperature up to +90 °C, using a mild liquid detergent.

Spin

After washing, you need to wring out the items carefully, without any effort that could damage the structure of the fibers. Machine spinning is also possible.

Drying

Dry clothes and blankets in an upright position. To prevent things from looking wrinkled when drying, they need to be placed loosely and the folds carefully straightened out.

Important! Synthetic fluff can be dried only in natural conditions, without exposure to the rays of the open sun, without the use of heating devices.

How to wash synthetic down in a washing machine

You don’t have to worry about how to wash a jacket made from synthetic down, because unlike synthetic padding, it will be much easier to do. For products with such filling, both hand and machine washing in a delicate cycle is ideal. Moreover, you can also set the drying and spinning mode.

- Synthetic fluff can withstand temperatures up to 90 degrees.

- After washing, the jacket should be shaken well with your hands, hung on hangers and allowed to drain off excess water.

- The material does not deform and perfectly restores its shape even after storage in vacuum bags.

Additionally:

- Bio fluff - insulation, what is it, properties and characteristics at the link.

- how to remove an oil stain from a Bolognese jacket;

In the video you can see the filling of pillows with synthetic down:

Let's talk about laundry

Fluff tends to bunch up and penetrate through holes in the seams, which negatively affects the performance of your unit.

If the fabrics from which the top and lining are made are not of very high quality, the fluff will also escape through the holes in the weaves. Important! Before turning on the machine, you need to put your jacket or coat in a special bag - then the fluff will cause much less harm.

After the jacket is washed, you will have to lay it out on a horizontal surface. If you try to dry it on a line or even a hanger, all the filler will end up at the bottom or in the corners. This, of course, is not a problem that will ruin your life forever. But after the product has dried, you will have to evenly distribute what is inside it and tap your favorite thing with the most ordinary carpet beater.

Important! In expensive models, the natural down is in special bags; it does not bunch up as intensively, but you will still have to dry the products on the floor and pat them down.

Synthetic pillow - what is it?

A synthetic pillow is the same pillow, with the only difference being that synthetic materials are used as filler.

Our century is characterized by rapid development of technology. If previously only natural fillers were used to produce pillows (down, feathers, sawdust, sheep wool, etc.), now they are increasingly made from synthetic materials.

Synthetic pillows have their undoubted advantages. This product is easy to care for and is relatively inexpensive. But there are also disadvantages:

- Synthetic bedding is not as durable as natural bedding - their service life usually does not exceed 7-9 years.

- Many people are confused by the word “synthetics” - they doubt the quality and environmental friendliness of non-natural things. But such fears are pure prejudice. Since the materials from which synthetic pillows are made must undergo special testing, and therefore cannot be harmful to health.

What criteria should you use to choose a down jacket?

When buying a down jacket or winter jacket, you need to take several parameters into account. The product should be comfortable, warm and comfortable. To choose the most suitable model, you need to consider the following criteria:

- Filler. When choosing clothes for winter, you need to take into account the rating of insulating materials, which determine how comfortable a person will be in a certain climate zone. For harsh winters, down jackets with insulation made from down, Thinsulate, or synthetic down are suitable. In this case, the density of the insulation plays an important role. In the northern regions, it is recommended to use things with a filling density of 300 g/m; for mild winters, it is enough to purchase a jacket with a less dense layer - 100 g/m.

- Weight. The lighter the down jacket is, the easier it is to move around in it. For people leading an active lifestyle, items whose weight does not exceed 1 kg will be optimal. A down jacket weighing more than 1–2 kg will hinder movement, so it is not suitable for sports and outdoor activities.

- Outer material and lining. These parts of the jacket should allow air to pass through and repel moisture.

- Model. There are many classic, elongated, voluminous, shortened, women's and men's models of insulated jackets. If in winter the air temperature drops below -15 degrees, then it is better to choose a long down jacket that will well protect not only the upper body from the cold.

Total: what is the best filling for pillows and blankets?

Each craftswoman determines the best filler for herself according to her own criteria: this may be convenience, experience in working with similar material, and economic reasons. We tried to make an objective review, during which we found out which filler is best suited for pillows and blankets according to the 6 most important requirements for the material.

| Filler | Sintepooh | Holofiber | Natural fluff | Bamboo | Thinsulate |

| Thermal insulation | 3 | 4 | 5 | 3 | 5 |

| Environmental friendliness | 4 | 4 | 5 | 3 | 4 |

| Hypoallergenic | 5 | 5 | 2 | 3 | 5 |

| Wear resistance | 4 | 5 | 3 | 2 | 5 |

| Exploitation | 4 | 4 | 2 | 4 | 5 |

| Price | 5 | 4 | 2 | 4 | 2 |

| Rating | 4,17 | 4,33 | 3,33 | 3,17 | 4,33 |

Based on the results of evaluating the properties, we determined the best filling for blankets and pillows - they turned out to be synthetic holofiber and Thinsulate. The structure of holofiber allows it to be used as the best filler for pillows, bumpers, soft toys and any other bulk products. Thinsulate is available in the form of a heat-intensive thin fabric, so it has established itself as the best filling for blankets on the market.

In the Decobay online store you can buy filling for pillows and blankets at low prices. We will provide fast delivery throughout Belarus; if necessary, a courier in the city of Minsk will deliver the order to your door. A wide selection of payment methods and a huge selection of high-quality fabrics to realize your bold ideas awaits you in the Decobay catalog!

Is synthetic warmer than down?

By preferring jackets with synthetic filling, we think that new technologies can combat the cold more effectively than down. However, both Arctic sleeping bags and suits for mountaineers are filled with down. This material has those elastic properties that make it possible to better retain heated air, and, accordingly, heat.

On the other hand, the emergence of new types of synthetic insulation makes it possible to compare the heat-protective properties of both. But just compare them, not contrast them. Good synthetics are certainly better than crushed chicken feathers.

Synthetics can be washed, but down jackets cannot?

This myth, again, was born in those days when down jackets, after washing, turned into a string bag filled with lumps and became unsuitable for further use.

In fact, you can wash both – with just one caveat. The synthetic filler itself is not afraid of water. But the feather should be handled more delicately, and here, oddly enough, washing is the acceptable type of care.

The fact is that in the process of preparing the feather filler, some of the natural fats and dirt that are on the bird are removed from it. However, not all fat is removed, since its particles give the filler water-repellent properties. When washing, these properties are lost, but gradually and very slightly, but dry cleaning can destroy them in one go!

Tips for choosing

podushki-iz-hollofaybera-7 podushki-iz-hollofaybera-6

The quality of sleep, brain and back health depend on the pillow. General recommendations to help you decide on a purchase:

- Ask the seller for a quality certificate. The product must comply with Russian Federation standards. This will help you choose a good thing and not a fake with a cheaper filler.

- Find out the product size and weight. The amount of filling for holofiber pillows affects the elasticity and height of the pillow. These parameters correspond to a comfortable position of the neck and head so that the blood vessels are not pinched. Pillow height = shoulder length. On average, for adults it is 10-14 cm. Broad-shouldered athletes may need 16 cm.

- There are different shapes of pillows, in addition to square and rectangle: circle, triangle, heart. But such options are recommended only for decorating a room.

- The density of the pillow depends on your usual sleeping position. Back sleepers need a medium-firm product. In a lateral position you will need firm support. If a person is used to sleeping on his stomach, it is worth buying a soft pillow for comfort.

podushki-iz-hollofaybera-5 podushki-iz-hollofaybera-15

A cover made from natural fabric is recommended. The sensations will be more pleasant, there will be no static electricity outside. It is desirable that the bedstead be removable. Then it can be washed separately from the pillow; there is no need to rip it out.

When choosing a pillow filled with holofiber for decoration, you should take a product with added foam crumbs. It is denser, better and will retain its original shape longer.

It is worth reading reviews about a specific manufacturer before purchasing. A high price may hide a low-quality product, but a little-known company may produce good products.

Alpolux

Modern artificial insulation Alpolux - what kind of material is it and what are its properties? The production technology for this filler was created in Austria. Alpolux consists of microfiber and natural wool. The wool content ranges from 15 to 30%.

Advantages

The main advantages of alpolux:

- high heat-shielding properties

- ease

- retains its shape and does not deform when worn or washed

- environmental friendliness

- does not cause allergies

Air passes through this filler freely, so you won’t be too hot in this down jacket or jacket. Alpolux is often used to create children's winter clothing, including discharge envelopes for newborns. However, in the production of adult outerwear, filler is also used.

Holofiber: what temperature and weather is it designed for?

Now there is a huge amount of outerwear with holofiber on the market. This is due to the low price. A down jacket costs one and a half times cheaper than a natural one. At the same time, it is not inferior in quality. Before answering about temperature standards, it is worth deciding on the density of the filler. The minimum operating temperature also depends on this figure.

Temperature standards:

- Density 100 g/sq.m. — from 10°С to 5°С

- Density 150 g/sq.m. — from 5°С to -10°С

- Density 200 g/sq.m. — from -10°С to -20°С

- Density 300 g/sq.m. – from -20°С to -30°С

Small red spots

Another consumer myth says: “Synthetics are a terrible allergen, but down and feathers are a natural product.”

Roskachestvo experts object: polyester is also hypoallergenic. Allergies or irritation can be caused by fiber ends that penetrate the lining and come into contact with the skin. But this is a question of the quality of the product as a whole, the quality of the lining, and not the polyester itself. Each insulation, before entering the product, undergoes textile preparation. The down is washed many times, odors and waste products of birds are removed from it. If this is not done, harmful microorganisms and parasites will remain in the feather and down material, which will bring a person much more problems than allergies. As for poor preparation of synthetic material. The fiber is formed and wetted using chemicals, which are then removed. Not removing them is like not rinsing the fluff.

When properly processed, both fillers are safe for health. If it’s bad, both are dangerous.

Prices

The cost of a synthetic fiber pillow depends on two factors: size and filling. Standard product sizes: 50x50, 50x70, 70x70.

- Synthetic fluff. The minimum price for the smallest pillow is 150 rubles. Large size products can cost from 200 to 300 rubles.

- Sintepon. The quality of pillows made from synthetic padding and synthetic feathers is approximately the same, so the prices are not too different. A small synthetic pad costs about 150 rubles, a medium one costs from 200 to 250 rubles, a large one costs around 300 rubles.

- Holofiber. A product made of this material measuring 50x50 will cost from 200 to 300 rubles, size 50x70 - about 400 rubles, the largest pillow - no more than 600 rubles.

- Artificial swan down. The prices for this synthetic filler are higher than the previous ones. A 50x50 pillow can be bought for about 500 rubles, while a size 70x70 will cost up to 900 rubles.

Synthetic pillows successfully combine low price and excellent properties. They are easy to care for, and in terms of practicality and hypoallergenicity they are superior to natural products. But it is better to purchase synthetic bedding from trusted suppliers - then there is a guarantee that their quality will be truly high.

Manufacturing and equipment

Depending on the raw material, synthetic fluff can be made from primary and secondary polymer .

The technologies for forming the fiber and producing the synthetic fluff itself are the same for both types of polymer.

For recycled polyester, pre-treatment operations are still required. The idea of processing PET bottles into synthetic fiber and then into synthetic fluff is very interesting from an economic point of view.

Let's take a closer look at how ordinary plastic containers turn into modern insulation.

Types of raw materials

There are several ways you can go here:

- Purchase waste PET containers , grind, wash and granulate them yourself. This is a labor-intensive and lengthy process, which has its own subtleties.

- Purchase ready-made clean flex flakes as raw materials . The most optimal option in terms of price and quality, since during the recycling process the polyester was not melted, which means it was not subject to thermal decomposition.

- Purchase granulated recycled PET . Such raw materials are ideal for further extrusion due to their bulk characteristics. But, alas, its composition and processing conditions are unknown. There is a risk of purchasing low-quality plastic.

Obtaining polyester thread

To form and draw threads from molten polyethylene terephthalate, you need:

- Extruder . This machine not only melts the polymer, but also thoroughly mixes and homogenizes it. The simplest and most inexpensive option is a single-screw machine. To work with flex flakes, it is better to choose a device with a large diameter in order to fill the auger as much as possible. Since recycled PET melts easily, the extruder length can be around 30-35D. The main condition is the presence of degassing, at least natural. Ideally, you need a vacuum pump. Removing volatile components will eliminate odor in the finished thread.

- Melt filter . Located at the exit of the extruder. When working with recycled materials, it traps dirt and foreign impurities.

- Melt pump . Installed in front of the die. Its main function is to pump the melt towards the head and maintain a constant flow as it exits the head. When working with flex, it is extremely necessary, since the filter allows you to reduce pulsation and make the finished threads more uniform.

- Filera . Usually there are about 200-300 round cross-sections with many holes. For textile thread, their diameter is 0.2-0.4 mm.

- Winding station . To be wound into bobbins, the threads enter through a chamber where they are cooled by air currents. Winding takes place on a system consisting of several rollers. An interesting idea is to apply a lubricant (organopolysiloxane) to the threads before winding by spraying. Surface treatment with silicone at this very moment will protect the thread from gluing and make the surface of the fiber insensitive to moisture from the air. The reels will be stored better.

More information about granulation equipment can be found here.

Synthetic fluff production

- To produce synthetic fluff, the threads must be formed into bales . To do this, the coils are threaded into the stand of the unwinding device, which then feeds them into the chamber. There the fibers are mixed and treated with silicone. The output is a tangled web, which is cut into pieces if necessary.

- The main piece of equipment is the carding machine. Many hollow needles, moving in different directions, comb the fabric. The needles, capturing the threads, destroy and finish them in different directions. Many air voids are formed . And the fiber, acquiring the character of a spring, becomes elastic and resistant to load.

- Package . Synthetic fluff is usually packaged in bags or briquettes . The vacuum packaging system helps to significantly save space during transportation.

What are they and how do they differ from previous analogues and natural fluff?

Time flows relentlessly and inexorably, days, weeks, months, seasons change. A beautiful winter is creeping up. Living in such harsh weather conditions as in Siberia obliges us to have certain skills in choosing ways to protect ourselves from the cold.

One of the most popular types of outerwear, combining such important qualities as: practicality, comfort, warmth, lightness and affordable price, are down jackets. The name, in this case, speaks for itself. To protect the body from exposure to low temperatures, previously only natural down was used as a heat-insulating filler. But in the modern world there are also many other materials that are created using innovative, progressive technologies.

So let's look at what types of fillings for down jackets exist now and compare the characteristics so that you can be prepared when choosing such an important wardrobe item.