Flocking refers to the technology of covering a surface with short fibers (from 1.5 to 6...7 mm) standing perpendicularly. Flock coating is small fiber fragments; glue is used to hold them on a substrate (fabric, films and other objects). After polymerization, it holds small-sized elements. The processing process itself is carried out in an electrostatic field, which allows the flocks to be oriented in a certain position.

To achieve abrasion resistance, quite stringent requirements are placed on adhesives. It is possible to vary the length and thickness of the flocks; you can get completely different sensations from contact with the resulting surface: velvety or abrasive-like. Flocked coating can have a wide variety of colors.

What is needed to start your own business?

Before you start work, you should study, select and buy equipment for flocking: flocker, flocking glue and material. If you live in a big city, then there will be no problems with this issue. Otherwise, you will have to purchase materials online in large cities, since many in small villages do not know about such a project.

Choosing a place to work is no less important. Working at home is highly not recommended, as the glue has an unpleasant specific odor and takes a long time to dry. It is important that the chosen room is warm and dry. Otherwise, you will be able to work during the winter. When designing a room, it is necessary to install a work table with grounding, as well as normal ventilation. Quality lighting is important. All this will require minimal costs, which will pay off in the shortest possible time. How much does it cost to open this business? Investments here are minimal and limited to the need to purchase materials for work.

To work quickly and fruitfully, practice is needed. It is with it that experience and skill will come to you. This way you can spend a minimum amount of time on preparatory work. If you are a creative person, you can be very creative in coming up with ideas for work and offering unique projects to clients. Otherwise, the Internet will help you, where there are a lot of interesting ideas and suggestions. So, how to do flocking yourself?

Flocking technology is simple, but practice is required to ensure that the products are flawless. Different materials have their own fiber length, density and application fit. To do the job efficiently and quickly will take some time and experience will come.

What can you offer clients?

- flocking walls;

- car flocking;

- flocking photo frames;

- flocking bottles and paintings.

Glue

Flock adhesives are available in both one and two part catalyzed systems. Plastisol and water-based adhesives are also available. Many of the adhesives have the consistency of plastisol ink.

Care should be taken when selecting a stencil or film emulsion that is compatible with the adhesive. Correct application of the adhesive is the most important part of the process.

A very heavy deposition of the adhesive is required, but at the same time the adhesive should not form a film on the substrate. Also, a coating that is not too thin should be used.

What do you need to know about the flocking process?

Flocking originated in China, where the entire process was carried out manually. Today, work is carried out using a flocator, which gives the fibers a negative charge and sprays them over the surface, securing the result with strong glue. You can buy a flocker in specialized stores or online.

The work includes the following actions:

- choice of coating surface;

- drawing;

- applying glue;

- flocking;

- drying process of the product.

It is important to do all actions as carefully and accurately as possible. Only in this case the end result will look perfect and have no flaws. Practice will help you with this and over time your work will be flawless the first time. Know that the price of a flocator depends on the power and manufacturer.

What is flocking

Flocking involves applying short fibers, usually nylon, rayon or polyester, directly onto a backing that has previously been coated with adhesive.

The diameter of an individual flock is only a few thousandths of a centimeter, and the length ranges from 0.25 to 5 mm.

Adhesives that capture fibers must have the same flexibility and resistance as the substrate to which they are applied. This process uses special equipment that electrically charges the flock particles, causing them to stand up. The fibers are then attached to the adhesive at right angles to the base.

The application is durable and permanent. Flock can be applied to glass, metal, plastic, paper or textiles. Applications of the technology can also be found on many items such as clothing, cards, promotional items, toys and book covers.

Nuances of choosing equipment

We recommend a Russian-made manual flocker. It is easy to use, has an optimal cost and meets all the necessary parameters of quality and reliability. You must select a product based on its power. The device must be able to adjust it. In this case, you will be able to work with both small and large surfaces, which will expand the scope of your work.

Glue is an integral part of the work. His choice should be taken seriously. It should be selected based on the surface on which the work is planned: glass, ceramics, metal, plastic or furniture.

And the most important element is the flock itself. You can buy flock for flocking on the Internet. It can be of several types:

- multi-colored;

- with elements that glow under ultraviolet light;

- for use in nail design;

- furniture;

- water repellent.

Flock must be of good quality and it is advisable to give preference to foreign manufacturers. As practice shows, they are more reliable, and the material will be durable and of high quality.

Flock application technology

To learn how to apply flock, there is no need to take specialized courses. Flocking technology is not complicated, but requires special care. Application stages:

- Prepare the selected surface.

- Apply a design (in case of designer flocking).

- Coat with glue.

- Apply flock.

- Dry.

The surface on which flock is going to be applied must be thoroughly cleaned and degreased. In order for the material to lie smoothly, the glue must be applied in an even layer. Since it has a transparent structure, it is easy to make a mistake with the amount applied to the prepared surface. Many flockers specially tint the glue before starting work to avoid unevenness.

Flock is applied using a special device - a flocker. It creates an electrostatic field, with the help of which the flock fibers are attracted to the glued surface. To consolidate the result, the product must be thoroughly dried. And so, having understood the flocking technology, you can judge what equipment you will need to open your own flocking business.

What are the advantages of surfaces treated with flock?

- Excellent surface appearance for a long service life. Flocking can turn an old item into an original item with an attractive appearance. You can also change the color scheme of your favorite item and give it a new look;

- Flock does not spoil due to temperature fluctuations and looks great even in the heat or cold. Protective functions allow it to be used under any conditions.

Today flocking is gaining popularity and demand in the market. It is you who can organize a profitable business with minimal investment, which will bring you an adequate level of income. When choosing materials for flocking, pay attention to reviews.

Starting a flocking business

This direction is not yet very widespread, little known in wide circles. Opening your own flocking business is promising: there is not much competition in the market yet, consumer demand is growing due to growing interest. Flocking businessmen have the opportunity to occupy an empty niche in their field. The technique of applying the material to the surface is simple; you need to purchase a flocking machine, additional equipment and consumables. Considering the narrow profile of the service and low prices for consumables, the business makes a good profit.

Where is flocking used?

The application is quite wide and it is difficult to even cover all areas where this area is relevant and in demand. Let's look at the main options:

Vehicle interior: roof, doors, control panel. The best option for those who work with auto tuning issues and interior reupholstery. If you are looking for creativity, you can even cover the outer surface of the car with flock;- Furniture. Over the years of use, scratches appear on it, and the color slowly fades and loses its original appearance. Flocking will allow you to restore old furniture at an affordable price and get the perfect option without spending money on buying new products. You can even change the color scheme, thereby updating the interior of your apartment or office;

- Nails. This is a unique option for creating a print addition. An interesting option for expanding the services of a beauty salon or manicure service;

- Processing of souvenir products. These can be gift bottles of alcoholic beverages, cups, wedding accessories, key chains and lighters. That is, everything that is given as presents and small gifts. Flocking will have a low cost, and the result of excellent quality will delight every client;

- Creation of individual surface designs for tablets, laptops and phones. This option will definitely appeal to young people who are constantly looking for unique options to stand out from the crowd;

- Working with walls. Flocking will allow you to create unique 3D images of any complexity at minimal cost.

This is interesting:

We are opening a business producing 3D floors.

Which press to buy for leather embossing?

Vinyl film car wrapping business.

Flocking the car interior - how to transform the interior? +

In the modern automobile industry, most parts inside the cabin are made of plastic. Such salons cannot be called original, but the situation can be corrected without drastic changes! Flocking the car interior is a great way to transform your car from the inside!

Flock - what kind of material?

Simply put, flock is finely chopped or chopped textile fibers.

The material is divided into two types - uncalibrated flock under a microscope will look like a mass of fibers of different lengths, but cut (calibrated) material is calibrated with high precision, down to fractions of a millimeter! Cotton, viscose, polyamide - half a century ago, flock was made from natural fibers, but today they have been replaced by synthetics, which are characterized by increased resistance to mechanical stress.

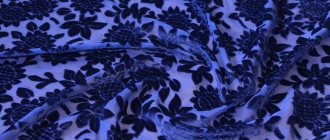

Depending on the size of the fibers, flocking can produce surfaces like suede, velvet or felt. Processing can be selective or continuous - in the latter case, objects are covered with a continuous layer of flock, regardless of shape and material. Selective flocking is possible thanks to stencils - only the desired part or interior detail is covered.

Applying fibers to the surface will not give the desired effect without special equipment - flockers. They generate a negative electrostatic field, due to which the fibers acquire the same position relative to the surface. Flockers come in both manual and stationary types – the manual version is suitable for flocking a car.

Flocking the car interior - is it possible to do it yourself?

In fact, flocking technology is not as complicated as it might seem at first glance.

Of course, most drivers will prefer to turn to specialists, because for self-processing they will have to buy equipment that certainly will not pay for itself in one “session”.

In any case, those who want to give the car interior an unusual velvet or suede look will need to know how the processing is carried out - at a minimum, you will find a common language with the master, and at most you will be able to make reasonable claims in case of poor-quality work.

To flock the car interior, all parts that will be processed must be dismantled and cleaned of dust and dirt. The plastic inside the interior can be different, and the treatment must be appropriate: if it bends, just go over it with sandpaper, but if it breaks, you need to treat it with a special compound - a primer, after applying which you need to wait 10 minutes.

Flock can be mixed, depending on what color or shade you would like to achieve. Then the material is poured into the flocator - there must be 1/3 of free space inside the container. Depending on the material from which the surface is made, you need to select the appropriate adhesive. Most often these are AFA11, AFA22 and AFA400.

Suede effect - flocking stages

One of the most important steps is applying glue. It is important to take your time, because if the glue is applied unevenly, the final surface will also be uneven. Particular attention is paid to the corners.

For plastic you need a little glue - the excess is removed with a brush, otherwise the flock will “sink” in a large layer.

If you are going to process materials that can absorb glue, for example, leather interior parts, then you need to apply more of it.

If you decide to do the whole process yourself, then for better visibility you can slightly tint the glue, so you can control the thickness of the glue. Flocking can be done in stages - this will not affect the quality.

If you decide to process surface details, then before applying glue you should highlight the desired areas with tape or masking tape. However, they must be removed immediately before flocking.

The workpiece should be grounded so that the flock does not fly apart. To be precise, the glue must be grounded, so when attaching the clamps, pay attention to whether they touch the adhesive.

The flocator and the table on which the part will be located must also be grounded. You can also hang it on hooks - it is important that you can get to it from all sides.

The handle of the flocator is usually made of metal, which must be grasped with your bare hand to ensure grounding.

When processing, it must be held perpendicular to the part at a distance of 10 to 15 cm. The flock must be applied in several approaches, after each time blowing off the excess flock with a hairdryer. For a high-quality coating, three layers of material are enough.

After flocking, the part must dry; at a temperature of 20 ° C, a day is enough. When the glue has completely dried, you should go over the part with a brush to remove excess flock.

You can read what a flocator is and how it works here. In this article we will look at the points and nuances when choosing a flocator.Faced with the choice of a flocker and consumables: flock, glue, we find a large number of ways to solve this issue. And, of course, all sellers claim that they sell high-quality and excellent equipment, and it is the best. Let's take a little look at the main proposals that a novice flocker faces from different angles in more detail.

Buy a diagram?

The first and very attractive idea is to assemble the flocator yourself. At the end of the 2000s, it even took on a terrifying scale. There were hundreds of sellers who sold and resold improved, modified, modified diagrams and manuals for assembling flockers, promising to assemble a flocker for several thousand rubles from scrap materials such as a car coil or a transformer from an ancient TV. This is where the absurd belief came from that a flocator is a simple device; such sites and topics on forums, of course, still exist here and there, but as relics of the past. Since in practice it turned out: the parts have not been produced for 20 years, the circuits are not working, either from other devices reminiscent of the flock circuit (for example, a Chizhevsky chandelier, a stun gun, an air ionizer, etc.), or the sellers did not send anything at all, pocketing money for yourself. There were, of course, people who tried to assemble the flocator themselves, but for this you need to have more than just the ability to solder. You need to understand the circuits, be able to draw them up, understand the element base and, most importantly, you need to understand what initial parameters and requirements should be in the flocator; in addition, you need to have equipment for measuring the output data. A more detailed article on the topic of homemade flockers is here.

Buy Self-assembled, artisanal?

This is the second and not the best idea that comes to mind: buy a ready-made self-assembled product from folk craftsmen. The cost is cheaper, there are a lot of offers, they appeared to replace the sale of circuits, apparently all from the same “enterprising” people. Of course, the thought motivates: save a few thousand, learn - what if it doesn’t work or doesn’t work out, save up and then buy a good one. But it’s impossible to learn from something that’s bad or doesn’t work correctly, and is there any point in paying a second time for a real flocker? A flocator is a complex electrical device that operates at high voltage. Assembled from improvised things that are not intended for electrical charges (a body made from a sewer pipe, a jar made from food containers, etc.), such a flock can not only disappoint in operation and discourage any desire, but even cause harm to health! There is a very detailed article on this topic here.

Stationary large

A flocker with an external power unit is, as a rule, an old flocker from the times of the USSR (at that time there was no such element base, and the dimensions of the parts were large).

Therefore, they were made with an external high-voltage source (in which the entire high-voltage part was mounted) and a high-voltage wire that went through the handle to the electrode. For its time, this was the norm, since there were no other options. It is a bulky, heavy block, which, as a rule, is installed permanently behind the workplace, because carrying it around is difficult. It is also necessary to monitor the integrity of the high-voltage wire, since over time it fails and breakdowns may occur.

Flocator from Chinese trading platforms.

Of course, the idea of buying various goods from Chinese manufacturers at an inexpensive price looks tempting, but this will not work with a flocker. Among the inexpensive Chinese models presented, devices are sold that are used for prototyping, creating imitation grass on dioramas and models. Their power is only 5-8 kV, which is very little, since an average of 50 kV is needed for normal charging and flight of the flock. We also note the very location of the electrode, which also serves as a grid on the hopper. Firstly, this is unsafe, since the electrode is open and you can accidentally touch it, and secondly, this arrangement allows you to work only by holding the flock strictly with the hopper down. With such power, it will not be possible to make a dense packing; the surface will end up with defects.

Expensive models are made according to the same principle and in addition have a remote unit, which we wrote about earlier.

Manual flocker

Manual flockers are currently considered the most universal. They are ideal for various works: auto tuning, souvenir products, flocking of printing and textiles, they can be used both in private workshops and in large industries. The structure, appearance and technical calculations were first made by German specialists, famous for their accuracy, precision and safety. They differ from stationary ones in that the high-voltage source is already located in the flock handle itself. This is safer and makes work easier. There are models of flockers that can operate not only from the mains, but also on batteries, this gives freedom of movement and the ability to work on-site. All spare parts and housing elements are designed and manufactured specifically for the flocker. The most popular today (it is worth noting and not only in Russia) is the Easy Set 70kV model flocker with the Vat function. More details here.

What is flock?

Flock, as it became clear from the last section, is a material that is waste from the textile (polymer) industry.

If translated literally from English, “flocking” means a bunch, combs made of cotton fabric, shreds. Fibers cut to the required length are called “flock”.

The role of raw materials for manufacturing is played by plastic, acrylic, viscose. Sometimes cotton, wool, polyamide and other materials are used.

The photo shows a flock with a flocker.

Flock, as a processing composition, differs in thickness, color and length. It is practical and easy to use, and its characteristics are similar to genuine leather.

It also has a number of advantages - the ability to “breathe” in hot weather and not “tan” at sub-zero temperatures.

Flock is pleasant to the touch, does not get wet, has heat-insulating properties and does not stain other fabrics.

If desired, it can be coated with special colors.

Today it is worth highlighting several types of flock, which are classified:

1. According to the material:

- Polyamide flock. Advantages: elasticity, ability to recover after taking loads, stylish appearance, wear resistance. Thanks to the listed qualities, it is used for flocking cars;

- Viscose flock is used in tuning (though less often) and for creating original products (velvet boxes, caskets and others). Pros - ease of processing, ability to paint. Minus - inability to return to shape in case of heavy load;

- Polyester flock. Feature - durability, resistance to moisture and sunlight. The downside is the difficulty of painting, which limits the choice of color palette;

- Acetate flock. Unlike the viscose type discussed above, acetate flock has less wear resistance and wears out over time. Advantages: plasticity and resistance to critical temperatures. This flock is used for processing artificial fur and interior elements.

2. Length:

- 0.5 mm. This flock has minimal consumption and is used in mass production of products without specific requirements for wear resistance. The material is used for processing rubber seals. Often products with a length of 0.5 mm are mixed with 1 mm “brothers”, which reduces their cost;

- 1.0 mm. This flock length is considered the most common. With its help, various surfaces are processed - wood, metal, glass, plastic, and others. The advantages of 1 mm material are pleasant to the touch, minimal risk of defects, ease of application. Used for flocking car interiors;

- 2.0 mm. The main advantage of flock is protection against abrasion. Products of this length are mixed with 1 mm flock, which makes the appearance original. 2 mm material is used for various purposes (primarily for decorating interior design).

3. By thickness:

- 0.9-22 dtex (measurement standard in the textile industry, characterizes the density of the fabric). The material of this thickness is wear-resistant, does not wrinkle, is soft to the touch and has a velvety appearance. Flock with a thickness of 3.4 to 6.8 dtex is used to create drawings, inscriptions, tuning car interiors, decorating packages and small-sized elements;

- 22-24 dtex. This flock is useful where wear resistance is required (for example, for covering carpets).

It is worth considering the pattern that the higher the dtex parameter, the harder the surface is. If we take flock with a parameter of 3.4 dtex for comparison, then it is softer than flock with 6.8 dtex.

When it comes to flock colors, there are many options. In recent years, fluorescent and matte shades have been increasingly used. The palette itself includes more than 20 colors, which simplifies the choice.

What is car interior flocking? What is its technology and essence?

Flocking in English sounds like “flocking”. The essence of such tuning is to apply a special material (flock) to the surface.

The main purpose of flocking a car is to change the appearance of the processed product, give it a modern look and protect it from negative influences.

Interior flocking is considered a new type of tuning. But it is not so. The technique was developed back in ancient times.

The pioneers were the ancient Chinese, who created a craft that resembles the technology popular today.

The Chinese used resin as a substitute for glue, which was applied to certain interior items. Afterwards, the treated area was covered with colored fibers, forming patterns of extraordinary beauty.

Initially, flocking was intended to decorate surrounding things and increase their value.

In its current form, the technology originated in the 50s, when excess production waste (for the textile industry) found application in flocking car interiors.

The essence of the technology is artificial surface treatment with a special coating. Here we are talking about flock, which has a synthetic base, but feels like velvet.

Unlike the latter, flock is more reliable and wear-resistant. In addition, it protects the surface from the negative effects of the atmosphere.

For car tuning, a material consisting of small particles of fluff is used. “Dust particles” of different colors are applied to a surface prepared and pre-lubricated with glue using a flocator.

Preparation of flock consists of cutting the fibers to the required length. If desired, the finished fibers are dyed, which opens the way for creating designs and patterns.

Today it is worth highlighting several flocking options. The most popular is using an electrostatic field created by a flock.

The essence of the “electric” method is that the fibers, after changing color, are amenable to chemical activation, or more precisely, to coating with an electrolyte. This process is necessary so that, under the action of the flocator, the fibers become 90 degrees to the surface being treated.

Advantages and disadvantages of flocking

Flocking the car interior has a number of features. The advantages of this type of tuning include:

- Originality of design, giving the car interior style and originality. This is due to the convenience of combining colors, applying logos or creating original designs.

- Color preservation for many years. Flocking has a solid resource and is not afraid of sunlight. In addition, flock does not fade over time, does not darken or lose shade.

- Resistant to temperature changes. Almost all surfaces wear out over time. The exception is flock. This material does not melt under high temperatures, is not susceptible to cold weather and, as already mentioned, does not wear out over time.

- Inability to absorb unpleasant odors. One of the main advantages of flocking a car interior is its immunity to odors. The renewed surface is not able to absorb dust, stench and cigarette smoke. In addition, the flocked surface has an electrostatic charge, which ensures that odors and dust are repelled even after 10 years of use. If a smoker drives, the flock will still remain fresh and clean.

- Sound and thermal insulation. Coating surfaces in the car interior with this material solves a number of problems in winter and summer. In the first case, the car stays warm longer, and in the second, it stays cool. In addition, less noise gets inside the car. This benefit of car interior flocking is often overlooked.

- Moisture and fire resistance. Flocking is an option for people who value security. Flock for car tuning is based on polyamide or polyester - materials that absorb water and do not ignite.

- Easy to care for. To care for the treated surface, you should use a cleaning detergent.

The disadvantages of flocking include:

- The high cost of this type of tuning. Not every car enthusiast can afford it.

- The surface is electrified (typical for some types of flock).

- The structure of the material is destroyed under the influence of products containing alcohol.

Reviews from car owners

The advantages or disadvantages of flocking a car are best described by reviews of people who have tried this type of tuning:

1. Dmitry, 30 years old, Moscow, VAZ 2108.

“After picking up the car from the workshop, I couldn’t be happier. The cabin immediately became more comfortable and even warmer in winter. Dust still collects, but due to the fact that the flock is light, it is not visible. Treat the surface with a damp sponge. I fight dirt with furniture cleaning compounds.”

2. Igor, 36 years old, Sevastopol, Volkswagen Passat.

“In the car I covered the plastic structures, doors and dashboard with flock. They say that flocking the interior protects against noise, but I personally did not notice it. Actually, I don't need this. The salon looks five stars and evokes a lot of positive emotions every day. The only negative is the higher costs ($500).”

3. Egor, 45 years old, Tomsk, Lada Kalina.

“The decision to flock the car’s interior took a long time, but the mechanic at the service station proved the promise of such tuning. He treated the flock on one of the cars with a rag soaked in gasoline and tried to tear off the material. No damage. But I believe that the main thing here is to choose an experienced master.”

4. Evgeniy, 29 years old, Krasnodar.

“I did flocking on a Toyota Prius. For several months now I can’t get enough of it. Friends and acquaintances who get into the car for the first time are surprised, my wife and children are happy. I don’t regret spending the money yet.” Evgeniy, 29 years old, Krasnodar.

Equipment and materials used

Before starting work on flocking the car interior, you should prepare:

- Flock. Volume plays a major role here. For processing 6-8 sq. meters of surface it is worth preparing 1-1.2 kilograms of flock. The cost of purchasing the material is 1000-1500 rubles. When choosing, you should pay attention to the material and color. The most expensive and high-quality is polyamide. Popular colors are gold, silver, bronze, blue, white, black.

- Flocator. When choosing, it is better to give preference to devices that provide power control and radius settings. When the power is reduced, the intensity of the flyaway is reduced, which guarantees accuracy when creating complex patterns and designs. The cost of a flocker ranges from 5 to 50 thousand rubles. The optimal price range in which flockers are sold is 15-20 thousand rubles.

- Glue. The composition of the adhesive required for flocking depends on the material used, usually plastic, metal, glass or textile. The adhesive option also depends on the type of application. Popular methods are dipping the element, using a brush or roller. In tuning car interiors, a brush is most often used. The cost of purchasing suitable glue is 800-1000 rubles.

- Auxiliary elements - primer, color, sandpaper and others.

Flocking. How to decorate a surface with velvet?

Recently, craftsmen have paid attention to an interesting surface design technique called flocking - with its help, the product acquires an original appearance. Despite the apparent complexity of the work process, anyone can master flocking.

Flocking technology - the basics of creativity

Flocking refers to giving a surface a fleecy appearance. The product becomes soft and pleasant to the touch. This effect is achieved by applying flock to the surface - fine chopped lint left over from the fabric.

Due to its simplicity of execution, the technology is used to decorate almost any everyday item.

Textile

flocking of was first started .

By gluing soft fibers onto clothing, a beautiful patterned design appears. For example, you can use flock to decorate individual print details on a T-shirt.

Manicure

Girls could not leave this technology unnoticed - quite recently, the salons of the world were captured by the mania for velvet nails!

A beautiful effect is very easy to achieve: the nail plate, previously coated with varnish of the desired color, is generously sprinkled with fluff so that there are no gaps left. This must be done while the polish is still wet so that the particles can stick to the surface of the nail.

Daily Use Items

Flocking gained real popularity at the beginning of the 21st century - with the advent of new technologies that make it possible to create batches of velvety products on an industrial scale in a matter of seconds!

You can see flocked computer mice, combs, gift boxes, and various souvenirs. The flocking technology is most often used in the design of jewelry boxes.

Bottles

Flocking gift bottles has become a real boom among crafters!

Since now your favorite noble drink not only tastes good, but also looks beautiful, it can be safely used as a gift.

Cars

Recently, motorists have a new opportunity to decorate their steel horse - car flocking! Decorating a car interior with a pleasant soft pile performs not only an aesthetic function - flock is considered one of the most durable coatings. It does not wash out, does not fade in the sun, softens extremely low and high temperatures inside the car, and is one of the materials that is difficult to ignite.

But flocking a car is more difficult than decorating all other items - the necessary part will have to be removed in order to decorate it separately, without staining the rest of the interior elements with construction dirt.

In addition to these basic methods, flocking is also widely used in scrapbooking to decorate cards, photo albums and envelopes.

Preparing for work

On the Internet you can find long lists and lists of necessary tools and materials that need to be purchased if you decide to flock surfaces. All these devices are very expensive and are only needed if you want to turn this design technique into your source of income.

To practice flocking as a hobby, you only need three things.

Flock

Flock is a short fabric pile. To make lint, as a rule, remnants of viscose, cotton, wool, and acrylic plain fabrics are used.

Craftsmen choose fibers of different lengths, depending on what product needs to be decorated. For example, in industry, flock of 0.5 millimeters in length is most often used - it is the least likely to fly apart when applied.

Flock 1 millimeter long is used where increased wear resistance of the coating is needed. In addition, it is softer and more pleasant to the touch than shorter material.

Flock is also distinguished by thickness - the value is indicated in dtex. Thus, material with a thickness of 0.9-2.2 dtex is used on an industrial scale due to its unpretentiousness. A thickness of 3.3-6.7 dtex indicates the possibility of application to car interior surfaces.

If you want to start making carpets, give preference to a thickness of 22 dtex.

Glue

Flocking a product involves the use of special glue depending on the selected surface. As a rule, the packaging of flocking glue indicates the parameters that must be observed.

For example, an adhesive may be suitable only for wood or iron, require pre-treatment of the surface in the form of sanding or priming, etc.

Flocator

A special device - a flocator - will help you quickly and correctly apply fluff to a large surface area - car parts, for example.

Correct flocking means that the fibers should be perpendicular to the surface and the glue on which they will be attached - this is the only way the surface will acquire a soft, neat appearance. In the photo below you can see the layer of pile number 1, which is correctly located in the layer of glue number 2, spread on the surface.

The properties of the flocator help achieve this result. When they get inside the device and are subsequently sprayed, the flocs are subjected to electrical processing - the flocker creates a special electrostatic field around the flock, which will help set the material in the desired position.

Working with electricity can be very dangerous, so take care of yourself first - before starting the process, ground the table you are going to work on according to the diagram shown below.

In addition, place a hood above the table so that the flock does not fly away in different directions, and do not forget to wear glasses with a respirator - the lint strongly irritates the mucous membranes when it gets into the eyes or nose.

Flocking technique – master classes

Since it is difficult to flock large surfaces, such as a car, at home, we offer you two simple master classes on how to give a velvety effect to postcards in two ways: using a glue stick and a stamp pad.

Stock up on special flock powder - you can buy it at a craft store or order it online. Flocking by smearing a picture with a glue stick helps you treat even the smallest details of the picture with a bonding agent.

- Draw the desired image on paper.

- Coat the drawing with glue. Apply the powder in a thick layer.

- Use your finger to straighten the fibers so that they stick evenly over the entire surface of the design.

- Brush off any excess powder from your work.

It only takes a few minutes for the drawing to dry. Use it as a decoration for a future card.

The second way to flock a postcard - using a stamp pad - is as simple as the first. The only thing is that you will need to ensure that the edges of the pillow and the pattern are always clearly aligned with each other.

- Cover the pad with paint of the same color as the powder and make a neat impression on the material. This will make the drawing look brighter.

- Rinse the stamp and wipe it dry. Apply glue to the entire printing surface and press it onto the already dried pattern, clearly connecting the contours.

- Without waiting for the glue to dry, sprinkle the surface with flock and leave to dry for a few minutes.

- After drying, shake off any remaining lint.

Your card is ready! Try using a similar method to decoupage a photo frame, box or pocket mirror.

To understand the intricacies of working with a flocker, watch this video tutorial - it will teach you how to flock car interior parts.

Source: https://megapoisk.com/flokirovanie-oformlenie-poverhnosti-barhatom

Surely you have ever heard the expression that everything new is well forgotten old. In our line of work – conducting business research – we encounter confirmation of this truth literally every day.

It happens that you find an interesting creative business idea related to the use of modern technologies, you dig deeper, and it turns out that it appeared several thousand years ago. This is what happened with the topic of our publication today – flocking.

But since, apparently, this idea was “forgotten” quite well, I decided to “raise” the project from the depths of centuries, shake off the dust from it, and present it to you for consideration.

Man has always sought to decorate his life, and, accordingly, everything that appears in it: clothes, household items, vehicles, etc. Since time immemorial, the best minds of humanity have struggled with these problems. In fact, they are still fighting to this day. Fortunately, modern technologies allow us to improve all processes. And minimize human participation in them. Same with flocking. But let's first define this term.

Brief business analysis: Costs of organizing a business: 50,000-400,000 rubles Relevant for cities with a population: from 150,000 Situation in the industry: average saturation of service offerings Difficulty of organizing a business: 2/5 Payback: up to 6 months

Flocking is the application of finely cut pile fibers - flock - in an electrostatic field to a variety of surfaces. Why is this necessary? First of all, like I said, it's very beautiful.

Secondly, flock performs protective functions. By the way, patriots of our country may be upset - this idea was invented in the States to reduce the amount of waste from the textile industry.

You can find out what other creative ideas are popular in America here.

Flocked items are just beginning their “march” across Russia, and therefore you have every chance to succeed in this type of business. It turns out to be an almost ideal option for implementing a business project: there are still few competitors, the costs of organizing a business are minimal, and the demand is already quite high. This happens very rarely.

Advantages of flocked surfaces

What is so good about a flocked surface? Why has flocking become so popular and is used in various areas of human life?

- The main advantage is, of course, the long-term preservation of an attractive appearance . A flocked surface can give a “second life” to an old item and preserve its “marketable” qualities. In addition, it becomes possible to experiment with different color schemes.

- Unlike many other materials, such as leather, paint, or plastic, flock does not change its properties under the influence of heat or cold, and therefore looks equally good in the summer heat and winter cold. That is, its protective functions are all-weather.

Flocking Process

If in ancient China, where, as mentioned, the craft of flocking originates, the entire procedure was carried out manually, in our time, knowledge of electricity comes to the aid of a person.

Today, the flocking process is carried out with a special device - a flocker, which gives finely chopped fibers a negative charge, and applies them by spraying onto the surface to be treated, coated with a special strong glue, and necessarily having the opposite charge.

Since all flock fibers have the same charge, they repel each other (remember the school physics course!), and, thanks to this, stand almost vertically on the surface. Depending on the length of the flock and the nature of the fibers, the surface of any product can be made:

- "under" suede

- "under" felt

- "under" velvet

At the same time, as I already said, you can choose a variety of color shades.

Where is flocking used?

The use of flocking today is so widespread that I will list only the main areas. Already having a general idea of what it is, you can come up with other, unusual ideas for flocking various surfaces.

- The most popular direction, in my opinion, is flocking the car interior: panels, inside doors, roof. This is an excellent option for those who are involved in car interior reupholstery and auto tuning. However, some originals also cover the outer surface of their car with flock.

- Flocking furniture, the surface of which becomes worn over the years (and having pets significantly speeds up this process). And since the cost of flocking is affordable to almost anyone, I believe that few owners will refuse to update the “boring” color of their furniture.

- Nail flocking is an excellent addition to nail printing services and may be of interest to entrepreneurs who have their own beauty salon.

- Processing of souvenir and gift products - champagne bottles, wedding padlocks, rings, key rings, lighters, cigarette cases, etc. Unlike laser engraving on metal, which I talked about some time ago, flocking services will cost much less, which means the demand for it will be much higher.

- Flocking the surfaces of laptops, mobile phones, computer mice, tablets, etc. - this proposal to make your electronic gadget creative is quite popular among young people.

- Flocking walls in rooms. Along with 3D wallpaper and phytowalls (descriptions of these business ideas can be found by following the links), this method of surface treatment allows you to obtain three-dimensional designs of varying complexity.

Flocking equipment

As you may have noticed from the sign given at the beginning of the article, the costs of organizing a flocking business are literally minuscule by today's standards. You can start your own business with only one manual flocker, which will cost about 12-15 thousand rubles.

Next, you will need a special glue, which is selected for flocking depending on the type of surface being treated (wood, metal, fabric, plastic, etc.), and the method of application to it (spraying, dipping, brush, roller, swab, squeegee, and so on.).

And, in fact, flock. As an example, I will give a table with prices for various types of material. When purchasing “consumables”, proceed from the fact that 1 kilogram of flock with a diameter of 1 mm can be processed up to 6 m² of surface, and up to 8 m² - with flock with a diameter of 0.5 mm.

Flock Fiber diameter (mm)dtexPrice (rubles per kg)

| Swiss “SwissFlock” (viscose) | 0,5 | 3,3 | 700 |

| Swiss “SwissFlock” (polyamide) | 0,5 | 3,3 | 1000 |

| trilobal | 1,4 | 3,3 | 1100 |

| fluor | 1 | 3,3 | 1100 |

To provide “large-scale” services for flocking large objects or large volumes, more serious equipment will be required:

- Compressor;

- Special chamber for flocking;

- Drying infrared chamber;

- Silk screen equipment;

- Painting tools.

How to organize a business

Depending on the size of the initial capital and the number of orders, to carry out the work you will need to rent a room of a suitable area.

You will definitely need official registration of your activity (you should not have problems with the tax service at the initial stage of business development). The most optimal form of running your business in this case is an individual entrepreneur.

A step-by-step guide to registering an individual entrepreneur can be found here - https://business-poisk.com/kak-otkryt-ip-samostoyatelno-poshagovaya-instrukciya-po-registracii-ip.html.

And most importantly, remember, if any obstacles arise in organizing your business, you can always write to me using the form in the “Contacts” section and get the necessary help. Good luck to you in your endeavors!

Once again about flocking in the video

Source: https://business-poisk.com/barhatnyiy-biznes-flokirovanie.html

Work order - instructions

When the listed tools are prepared, it is worth starting the flocking itself.

The sequence of actions is as follows:

- Choose a room for processing. The main requirements are sufficient lighting, ventilation and comfortable air temperature (20-25 degrees Celsius).

- Dismantle the part being processed.

- Wipe the surface from dust and dirt. At this stage, it is worth inspecting the surface for defects and damage.

- If dents, breaks or cracks are found, putty and smooth the surface using sandpaper.

- Coat the knot with a primer that improves the effect. The product is sold in two forms - aerosol or solution. Purchase costs - 400-500 rubles per 100 ml.

- The plastic part should first be degreased with alcohol or white spirit, after which you should start flocking the interior.

- Dilute the glue and color it with dye. Thanks to the use of color, it is possible to disguise elements of the part that are inaccessible to the flocker. In extreme cases, you can use a brush

- Apply glue to the part that is being flocked. If the goal is to make an original pattern, then the space for flocking should be prepared in advance. To do this, use tape.

- Prepare the flocking composition by pouring the “blanks” into the flocker.

- Set the required power to the device and get to work. The flocator should be kept at a distance of 12-15 centimeters from the surface, which guarantees uniform application of the composition.

- Once the first layer is applied, the surface is blown off with a hairdryer, after which the second layer is applied. As soon as the product dries, carry out the finishing treatment with a vacuum cleaner or brush.

- The schematic diagram of the work looks like this.

If the technology is strictly followed, flocking will be smooth and beautiful to look at.

Methods of application

Decorative flocking is carried out using one of four methods:

- electrostatic;

- block/gravity;

- spraying and;

- translation.

- The electrostatic method is perhaps the most effective flocking method, especially for a printer doing more than occasional work.

- The flock material can also be sprayed using an air compressor, tank and sprayer similar to spraying paint. It is mainly used when large areas are required. This is an untidy process because some of the flocking fibers remain in the air.

- Flocking is also applied by printing an adhesive onto a substrate, and then rapidly vibrating the substrate mechanically while the flock fibers are distributed over the surface (see picture below).

Vibration increases fiber density, which is critical for good fiber and causes the flocking fibers to stick to the adhesive and pack into the layer. This process is called bar or gravity flocking system and is basically a mechanical process.

In this process, flocking fibers adhere randomly to the surface of the substrate, and each fiber adheres to the adhesive at a different depth, creating an irregular surface.

Because the fibers stick to the surface of the adhesive rather than penetrate or insert into it, some fiber tearing occurs. Loose flocking fibers created during production also tend to migrate, so many of these systems are installed in a separate area to prevent fiber contamination in the plant.

- An easier way to add flocking to your operation is to purchase and apply a standard flock transmission. Another choice is a patented process where the transfers are multi-colored, highly detailed, and produced without ink.

Flocking provides an alternative, value-added decorating technique to achieve this unusual look. It costs a little more than creating a standard screen print combined with textiles, but it is certainly cheaper than embroidery. This process uses dyed nylon fibers that are charged and injected into the structure. Standard flock transfers may also need to be done in-house.

Read about: how silk fiber is made: the worker caterpillar.

Basically, pre-printing is essentially the same as screen printing with a few differences. Screens are made of a coarser mesh and some illustrations may need to be thicker. Glue and crystal powder are applied to the transfer and then sent through the dryer at low temperature.

This removes moisture from the glue but does not melt the crystalline powder. Excess powder is removed and the transfer is sent through the dryer a second time to chemically bond the powder to the adhesive.

Features of the work - what is worth knowing?

When flocking, consider the following:

- Before applying flock, clean the treated surfaces from dust and dirt;

- It is not recommended to flock interior parts that have scratches, chips or cracks;

- Cover the surface with flock only after thorough processing (cleaning) of the part;

- If stains appear on the flock, remove them immediately. If they dry out, it will be more difficult to remove the contamination. The algorithm of actions is as follows: moisten the material with water and go over problem areas with a soft sponge. The use of soap solution is allowed;

- Clean the surface with a napkin or towel. It is allowed to use a brush with soft bristles.

Electrostatic system

Electrostatic flocking equipment is available in three configurations:

- automatic carousel for multi-color flocking;

- a single flocking unit, which is usually attached to one press station;

- portable unit for lower volumes.

Equipment costs range from hundreds or several thousand dollars for manual units to tens or hundreds of thousands of dollars for automatic multicolor systems. All equipment operates using the same basic procedure. In flocking, an electrical charge is generated using two electrodes: a high-voltage DC grid connected to a power generator and a grounded substrate.

An electrostatic charge is generated which propels the fibers at high speed towards the adhesive-coated substrate. This causes the flocking fibers to penetrate and bond into the adhesive at right angles to the substrate. This creates even coverage.

Controlling the electric field, by increasing or decreasing either the applied voltage or the distance between the electrodes and the substrate, controls the flocking speed and thickness.

Handheld devices

Hand-held devices consist of a metal plate, a generator and a flocking head. The metal plate must be grounded and can be placed wherever it is convenient. This is the equivalent of a plate on a textile press. The generator creates an electrostatic charge and is connected to a canister that contains loose fibers. The metal screen is mounted halfway inside the canister opening.

The open end of the container is then passed through the adhesive-coated backing, drawing the fibers out of the container through the screen. The electrostatic charge pushes the fibers toward a grounded metal plate. The adhesive coating of the substrate intercepts the fibers and flocking occurs. The substrate is then cured in a conventional textile dryer and loose fibers are removed by shaking, vacuuming or using compressed air.

Watch the video of how T-shirts are flocked:

Advantages and features of coating

Flocked flooring not only has an elegant look due to the ability to organize different shades and patterns, but also has a number of other advantages:

- The floor surface will have soundproofing properties. The structure of the flocked coating will effectively absorb noise in the room;

- High strength of the product. Despite its apparent fragility, flocked flooring is very resistant to stretching and tearing. This floor surface has excellent wear resistance parameters;

- High resistance to fire. Refractory materials used in the manufacture of the coating provide effective resistance to the spread of fire;

- Light resistance. This surface is not prone to loss of color intensity under the influence of solar radiation;

- Proper organization and treatment of the floor will not allow the accumulation of foreign fractions on its surface: dust, condensation, moisture.

In Europe and Russia, flocked flooring from the Flotex company is common. The brand's products are recommended for their high quality and compliance with environmental safety standards in the home. The floor from the English manufacturer has a BRE certificate, which confirms complete safety for people such as interior decoration. The international standard ISO-14-001, which marks the flooring surface, confirms its quality, practicality and minimal environmental impact at all stages of production and use.

Flocking stands

In our advertising and production company you can place orders for the production of flocked gift stands for balls for football, basketball, and volleyball. You can also place orders with us for the production of flocked golf ball tees. The flocked gift stand is very beautiful, presentable, and velvety to the touch. If you decide to order a personalized ball as a gift, a flocked gift stand will be an excellent addition to your present. You can order flocked gift ball coasters from us in quantities starting from 1 piece. You can choose the color of the flock from the catalog presented on our website.

Types and collections

Depending on the finish and relief of the product, color palette and type of pattern, several collections of flooring are distinguished.

1. Flotex Classic flocked flooring is available in 8 sub-collections. The product itself is distinguished by antibacterial properties due to the application of a special protective layer during production, high reliability and wear resistance. Classic collections can be a continuous flooring design, as well as a pattern with minimal expressiveness or a clear geometric shape.

This variety will allow you to give the room the desired look and organize a suitable design. For example, Flotex Berlin with the correct geometric pattern would be appropriate in a formal office. The Dakota sub-collection impresses with its large number of possible flooring patterns (20). Flotex Montana is characterized by the possibility of choosing almost any shade of color to create an elegant interior. Flotex Senya has a soft pattern that will complement any home interior.

2. The Flotex HD collection will add expressiveness and beauty to the flooring thanks to the implemented digital printing technology. This allows you to provide a 3D effect, which always looks original and modern.

3. Flotex Tiles - an original solution for creating an exclusive floor covering. Here you can highlight rolled materials, as well as designs for tile materials. The Tiles collection is a flocked floor in the form of fancy combinations and geometrically regular shapes of segments of varying color intensities. The floor looks modern and amazing.

4. The Flotex Sottsass collection allows you to amazingly create a pattern directly on the floor covering, which will become the pinnacle of design ideas when decorating an interior.

5. Flotex Naturals - conveys wood grain patterns.

Flocked flooring: production and technical characteristics

An artificial velvet floor covering is formed due to the reliable attachment of the pile to the adhesive base of the base.

For the production of pile the following is used:

- Nylon;

- Polyamide;

- Viscose.

This mixture of natural and artificial fibers ensures not only uniform distribution over the base, but also high strength and lack of tendency to accumulate dust. The applied flock can reliably hide minor flaws in the base. Moreover, damaged areas can be quickly restored.

This floor consists of several layers:

- Stabilizing fiberglass;

- Vinyl backing;

- Pile.

Separately, a Sanitized (antibacterial) layer can be applied to the surface. Flocked flooring is produced in rolls and tiles. The dense structure of the product allows for high moisture resistance. The wear-resistant dense pile and its reliable attachment to the base allow users to enjoy the floor covering for many years.

A special visual effect can be achieved using digital printing technologies. As a result, not only a design, but also valuable wood species can be depicted on the flocked coating. Many people choose flock to create an original “soft” parquet floor.

Images of valuable wood species can also be successfully created on flock: beech, hornbeam, beech. Flock is scratch and abrasion resistant; it can be cleaned without problems using a vacuum cleaner. Flocked flooring is not as demanding to maintain as parquet or laminate.

The cost of starting a business

At the initial stage, you will need the bare minimum of equipment and materials that you can imagine. Costs will be spent on purchasing equipment and consumables, renting premises and hiring personnel, since it is difficult to apply glue and hold the flocker alone. Another question is that the positions of designer, accountant and marketer can first be combined in one person.

So, in order to open a business, you will need:

| Name | Amount (minimum) in rubles |

| Flocator | 16 000 |

| Compressor | 10 000 |

| Drying | 15 000 |

| Stencil machine | 11 000 |

| Camera for 3D application | 9 500 |

| Tools | 9 000 |

| Flocking adhesive | 1 600 |

| Flock | 5 000 |

| Total | 77 100 |

This list of costs does not include premises rental, staff salaries and advertising costs, as it is minimal. The price of a flocator can be higher or lower, depending on its functionality and quality. To start your own business, the listed expense items will be enough. The cost of the service can be calculated taking into account what materials were used for flocking, in what quantities, how much labor and electricity was spent per square centimeter. On average, you can set the price at 30 rubles, but vary it depending on the complexity of the design and the surface of the product. Thanks to low competition and growing popularity, you can make very good money from such a business.

Prices for flocking yourself and in the salon

You already know the approximate prices for materials and equipment for flocking. By the way, you can make a flocker yourself (see instructions here). And, if you at least roughly calculate the total amount for everything you need, you will get a minimum price of 7,500 rubles.

And now about the prices for flocking in specialized salons. The cost of covering one door in the cabin with flock will be around 1500-2000 rubles, the dashboard - 4000 rubles, the sun visor - 500 rubles, the ceiling will cost a little more - 4000 - 5000 rubles due to the complexity of execution. However, it should be borne in mind that the cost largely depends on the make and model of the car, the shape and size of the flocked part, the desired pattern, the level of skill of the specialist, the materials used and many other factors. So, only you can decide for sure what is better and cheaper - to do flocking yourself or go to a salon.