Production and composition

The smooth surface of the fabric is obtained due to the satin weave of the threads during the fabric manufacturing process. Satin silk is woven in two threads - warp and weft. The warp threads mostly overlap the weft threads, resulting in a smooth, shiny front side and a matte, rough back of the satin fabric.

Satin weave

Also, silk satin can be double-sided, where the face and back have a smooth shiny surface. This is due to the fact that the warp threads are on either side of the weft thread.

Initially, the composition of satin silk fabric included exclusively natural threads, which made the satin expensive. But to make the fabric more affordable, cheap threads are added to it: viscose, cotton, polyester, nylon and acetate. Of course, the quality of mixed fabric differs from natural silk, but they are also popular because their price is much lower.

Historical reference

Over the centuries, real legends have been formed about the amazing properties of atlas. Even the name of the fabric itself means “smooth” in Arabic! But the technology for making this material came to us not from Persia, but from China. More than two thousand years ago, skilled weavers developed a special method of weaving threads, which made it possible to create an exceptionally smooth, perfect texture based on silk thread, which was loved by members of the imperial family. Clothes made from such fabric, due to the rarity and complexity of the technology, became a sign of belonging to the highest social strata.

As time passed, satin fabric gained popularity far beyond the borders of Asian countries, becoming the privilege of nobles and nobility in Europe and Russia. But until synthetic fibers were invented, satin production remained small-scale. Only with a technological breakthrough did it become possible to reduce the cost and mass industrial production of atlas of various types. By the middle of the 20th century, the atlas became available to almost everyone.

Types of satin fabric

Satin fabrics can be divided into two groups: according to the density and texture of the fabric, and according to the type of pattern applied.

By invoice

- Duchess is a very dense satin, where the threads are tightly intertwined with each other.

- Crepe satin is a double-sided rough material, very soft and shiny.

- Crash is a shiny crinkled fabric, thin and light.

- Stretch satin is a material with the addition of lycra or elastane, which allows it to stretch and better fit the figure.

- Satin satin is made from cotton and silk threads; its thread weaving is somewhat different from satin weaving and its surface is not so smooth.

- Dupont satin - Very dense and very shiny satin compared to other types.

- Taffeta is made from tightly twisted threads of silk, cotton or other synthetic fibers. At the same time dense and very light material.

By pattern type

- Embroidery is done on top of the finished fabric on a special embroidery machine.

- Thermal embossing looks like an impression and is done with a hot roller.

- The printed design is applied using special ink on a printing press.

- The jacquard pattern is made on the front side of the fabric using a new thread weave.

Advantages and disadvantages

The atlas has the following features - pros and cons.

pros

- Attractive appearance.

- Pleasant to the body.

- Beautifully fits the body emphasizing its features.

- Antistatic, but this only applies to natural fabrics.

- Strength.

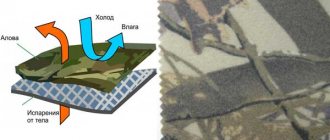

- Hygroscopicity.

- Breathability.

- Opacity.

- Easily amenable to assembly, draping and other technical changes.

- Dries quickly after washing.

Minuses

- Wrinkles when actively wearing the product (pants or skirt).

- Uncorrectable puffs may form.

- Shrinks when washed in hot water.

- The fabric cut is very frayed, so it must be processed using an overlocker.

- Thin synthetic or mixed satin can stretch.

- Also, unnatural satin attracts dust, which is visible on clothes.

What is sewn from satin?

Satin material is very popular in the production of various types of textiles. First of all, elegant dresses for evenings and weddings are made from it. They use natural fabric or with a small addition of synthetics (crepe, crash, satin).

Textile decoration for halls of special events and banquet halls uses bright satin, which is cheaper in cost.

Home textiles are not left without satin items: men's and women's pajamas, satin bed linen, shirts and just home suits. It is worth noting that it is better to sew satin products of this kind from 100% natural fabrics, since synthetic fabrics accumulate static electricity and become electrified when rubbing against the body.

Elegant curtains made of heavy satin fabrics transform the interior into a rich and luxurious one. When sewing such curtains, it is worth considering that satin curtain fabric is heavy, and under this weight, long curtains can sag. To avoid this, you need to seal the top edge with an additional layer of fabric.

In the production of pointe shoes for ballet and other lightweight shoes, a special soft and durable shoe satin is used.

Cheap synthetic material satin is used as a lining for outerwear. More expensive when sewing concert costumes for singers and dancers.

Children's elegant clothes are sewn from bright satin fabrics with or without patterns.

Properties of satin, advantages and disadvantages of fabric

The special sliding texture and shine make satin a very effective and elegant material. But that’s not the only good thing about it! What else is different about this fabric, thanks to which it has not lost demand and popularity for centuries?

Let's start with the positive properties of the fabric. The obvious advantages are:

- Drapability of satin. Falling numerous soft folds make it possible to create incredibly feminine, original styles.

- Noble appearance is a complex characteristic that includes shine, radiance, and ultra-smooth texture. It is due to these properties that satin has become popular in evening fashion.

- Long service life. Thanks to the special weave, satin is a wear-resistant and durable material.

- Air permeability and hygroscopicity. In the case of satin made from natural raw materials, these characteristics are obvious; modern materials (polyester, viscose assortment) also meet all hygienic requirements and can be used for second-layer products (not for sewing linen).

The atlas also has disadvantages, which arise mainly from its advantages.

Working with a smooth surface is not easy: the cut may crumble due to the peculiarities of the weave, and snags may appear if you work carelessly with the fabric. If not properly cared for, fabric made from natural threads can shrink, and fabric made from synthetic raw materials can become electrified.

How to care for things made of satin

Satin fabric is expensive and fancy, which means you need to take care of it carefully. These are the basic rules, adhering to which the thing will remain intact and attractive.

- Wash either by hand or on a delicate machine wash.

- Choose products for gentle washing. Maybe specifically for silk.

- Using powders with aggressive stain removers and chlorine can damage the surface of the fabric and ruin its color.

- It is better to squeeze it by hand, as the drum of the machine can tighten.

- Satin items should be washed separately from others, while fastening all accessories. This will help avoid damage to the fabric.

- Products should be dried vertically in a straightened form.

- Iron satin items using damp gauze and a not very hot iron.

- To prevent the item from becoming electrified, treat it with an antistatic agent.

Customer Reviews

Based on customer reviews, we can conclude that the best thing, of course, is natural satin. But this does not mean that synthetic or mixed fabrics are not worth buying.

Lyubov, seamstress at home: I often sew school costumes for various performances from inexpensive synthetic satin. The outfits are bright and serve the school for many years.

Anna, fashion designer: in our salon-atelier we often sew chic wedding dresses combining several types of satin. Often this is a dense, heavy material as the base of the entire dress, and light taffeta or crush as the upper airy layers.

Olga: As a public person who often performs at concerts, I have to change outfits often. Satin dresses of different colors and cuts are my thing. They look elegant, aesthetically pleasing, and are inexpensive.

Satin ribbons: history, production, scope of application

Satin ribbons: history, production, scope of application Satin ribbon is a common textile product, the raw material for which is viscose (less often acetate) silk. The nomenclature list includes bleached and plain-dyed varieties of different colors, lengths and widths. The high commercial value of the tape is due to the wide scope of its use, and this is already a merit of the special technological characteristics, aesthetic properties of the product and manufacturers who maintain the quality and range at a decent level. History of satin ribbon

This is one of the very first decorations of ancient man. The decor in the form of braid, made by twisting plant fibers, was woven into the hair, creating the first hairstyles with its help. Sites with amazing finds have been discovered in different parts of the planet. In ancient times, they were already used everywhere, but only wealthy people could afford such exquisite decoration. Smooth multi-colored cuts were made from expensive natural raw materials (linen and cotton). They were embroidered with gold threads, decorated with precious stones and coins, so they were beyond the means of the poor.

Another version of the origin of the satin ribbon leads to Ancient China - it was in this state that silk was first produced. In the 14th century, expensive imported fabric fell into the hands of Europeans. Another history of the satin ribbon began, connected with its use in completely different niches of human existence: in some states it was used as an expensive feminine adornment, in others only representatives of high classes wore the ribbon, and in others they endowed it with sacred properties.

Modern production of satin ribbon

The product is included in the category of decorative and finishing ribbon weaving products (according to trade classification). To enhance the aesthetic properties, synthetic threads and yarn are used instead of natural raw materials. Before weaving, viscose is dyed in bulk, since when processing finished threads it is almost impossible to avoid different shades.

In the production of satin threads, viscose with a density of 8-29 tex with a twisted, pneumatically connected or caned structure is used. You can achieve enhanced shine by replacing viscose threads with acetate ones. Each group of ribbon weaving products has its own quality control method. Satin ribbons are tested for dye resistance to chemicals, ultraviolet radiation and high temperatures, thus controlling the reaction to laundry detergents, sun and ironing.

There are 3 main ways to decorate satin ribbons:

- Hot stamping: company logos are applied. Decorate with soft toys, champagnes and vintage wines, etc.;

- Thermal rise: a type of relief printing. It has a convex structure. Used in the production of advertising products (envelopes, invitations, business cards, etc.);

- Full color sublimation printing: the dye penetrates deep into the fabric. The result is a smooth image that does not fade under the influence of ultraviolet radiation. Very deep rich color. Wide choice of shades. Products do not lose their novelty for a long time. Often used as an accessory for carrying passes and phones.

5 main properties of satin ribbons

The products have 5 main characteristics:

- Beauty: due to mirror shine, rich colors, various decorative inclusions;

- Tensile strength: achieved through the use of high-quality raw materials and dense structure;

- Resistance to negative environmental influences: the fabric does not fade, maintaining its original brightness after repeated washing and ironing;

- Rich assortment: easy to choose by length, width, shades, level of smoothness;

- Affordable price: synthetic fabrics are cheaper than natural ones.

The material comes in lightweight, convenient spools. Well protected from moisture and dirt during transportation.

Areas of use of satin ribbons

The products have pronounced decorative properties and are widely used:

- As a hair decoration;

- Original interior accessories, made by yourself: from simple ruffles and bows to tablecloths, panels, curtains, bedding sets, etc.;

- In floristry - to complement bouquets;

- In the manufacture of hairpins, headbands in the form of bows, flowers;

- For embroidery and other types of home crafts.

Gift boxes are tied with satin ribbons (which you can buy in bulk here - www.moskva.star-tex.ru/furnitura/lenta/atlasnaja/). They are included in discharge kits for newborns. They decorate wedding cars, tables, and curtains. Inscriptions such as “Graduate”, “Honorary Witness”, “Happy Anniversary”, etc. are placed on the ribbons. Black products are ordered by companies providing funeral services. State paraphernalia, decor of a banquet hall, a beautiful picture with a sea of flowers and a small box with a surprise tied with a beautiful ribbon - for these and other purposes they use a simple universal textile item that came from time immemorial.