Batting

is a knitted or non-woven fabric made of cotton, wool or wool blend yarn with fleece, used for household purposes as insulation.

According to its characteristics, this material is very similar to cotton wool. It is just as warm and airy. Batting (in French ouatine ) is the name given to the cotton wool material used for lining, the basis of which was mesh fabric.

Many people associate the word “batting” with the concept of old-fashioned winter clothing - good quality, very warm, but at the same time heavy and somewhat clumsy. Meanwhile, this material has long been the most popular heat-insulating textile, which was used not only for clothing, but also for many other purposes. padding polyester are now widely used for everyday winter wardrobe , there are many industries where practical and reliable batting still remains unrivaled.

What is batting?

Like many other types of textiles, this heat-insulating material began to be produced in France (the literal translation of the word ouatine is fleece).

In search of a cheap replacement for the traditional fur lining of winter clothing of the time, a non-woven material was invented, consisting of cotton or wool wadding attached to a mesh fabric.

Batting has been extremely popular and in demand in the past century. It insulated not only work clothes, but also the winter outfits of city dandies. Fashionistas of the 40s and 80s of the 20th century did not refuse it even in evening dresses: hangers for blouses, dresses and jackets were made from this material.

Warm and inexpensive batting, especially wool, quickly gained popularity not only among people of low income. Even wealthy ladies appreciated its ability to create a fairly thin and dense padding, which not only warmed, but also gave the silhouette clarity and the shape required by fashion. Batting padding was used for women's coats and jackets, forming fluffy folds of skirts and creating puffs on the shoulders, and warm hats. Shoulder pads made of this material were a mandatory part of a fashionable wardrobe in the middle of the last century, and returned briefly in the eighties, although then padding polyester , foam rubber and other pads were already used for this purpose.

The secret of the cheapness of batting was that they used cheap raw materials - not very high-quality cotton , scraps of wool and cotton fabric, and even linen waste. The production scheme of this non-woven material has not changed for centuries:

- Collection and preparation (cutting) of raw materials, mixing them in the required proportions if necessary;

- Regeneration, that is, the separation of raw materials into fibers using pinching machines.

- Combing fibers and distributing them evenly;

- The formation of an insulating layer of specified dimensions and density can be carried out in one or several layers.

- Quilting the insulating layer, as well as fastening it to the fabric.

According to the method of fastening the fabric, batting is divided into:

- non-woven needle-punched, when the fibers are fastened together with vertically arranged dense stitches. It is inexpensive, soft, although it does not have very high heat-insulating properties and wears out quickly.

- The knitting and stitching material is fastened with cotton or synthetic threads, the stitches of which are arranged in a herringbone pattern. It is more durable, although more expensive than its needle-punched counterpart.

- durable and dense batting on gauze that does not shrink, but is now produced quite rarely.

The most expensive is wool material, which provides the same thermal insulation as real fur . It is practically non-flammable, so it is better suited for workwear intended for high-temperature environments. In second place for these purposes is cotton batting on gauze.

However, most modern materials in this group are made from a mixture of recycled wool yarn, cotton and synthetics. For technical batting, the addition of flax “shaking” is also used - sorted short flax fibers.

Description

Batting is a filler that makes canvas stitching unattractive, but practical. Often used as an insulating component, filler for quilts, furniture, or for wet cleaning of the house. The material was developed in order to reduce the cost and replace the standard fur linings at that time. Requiring careful care.

This filler is most often synthetic or wool blend; it has a high density and retains heat for a long time. The material was used not only for work clothes, but also for ladies' outfits, as the clothes, lined with batting, look noble. Coats and dresses retain their shape and give the figure a clear feminine silhouette. The low price is explained by the fact that recycled materials are used for its production.

Manufacturing methods and price differences

Batting is made from sewing waste, such as wool , viscose , cotton lint, cotton wool, etc. The scraps of these materials undergo special processing and are rolled into fabric. There are several ways to make such material.

According to the manufacturing method, batting is a non-woven or knitted material. It can be based on sewing or weaving waste. Synthetic, natural or regenerated fibers undergo special processing, after which they become loose and fluffy. They are evenly distributed and joined by special machines.

- Needlepunched . Equipped with tightly spaced needles. They bind the fibers with vertical stitches. This type of batting is sometimes called non-woven needle-punched fabric. This type of material is not very durable, but has the lowest cost.

- Knitting and stitching . It binds the fibers together with very decorative parallel stitches, reminiscent of a herringbone pattern. The batting is called canvas-stitched . It is more durable than the first, but also costs 20-25% more due to the use of additional cotton or synthetic threads for stitching.

The most expensive and durable fabric is fabric placed on gauze. This technology eliminates deformation of products and increases their service life.

The cheapest is non-woven needle-punched batting. It is made by fastening fibers together with many needles. The disadvantage of this canvas is that it is not very durable. Canvas stitched fabric is more expensive because its fibers are sewn together in parallel stitches using cotton threads. This fabric has a longer service life due to good bonding.

There is another type of non-woven fabric, which is much more expensive than the previous two. It is sewn onto gauze so that it does not deform over time. Due to the use of materials such as gauze and thread, lined batting costs several times more. Since the insulation itself rolls off and wears out over time, this technology significantly increases its service life. The color of the canvas depends on what raw materials it is made from. wool was used for production , then it is usually gray , if cotton fabrics were used - white .

Reviews

- Marina Vladimirovna, 37 years old : “Batting is a universal material with which you can create very warm outerwear. It helps to retain heat just as well as fur liners. If the product is properly cared for, it will not lose its shape or performance characteristics.”

- Vadim Eldarovich, 42 years old : “I work at a construction site. Our workwear is all sewn on batting. In the most severe frost it protects from wind and cold. However, there is one inconvenience. The jackets and pants themselves are heavy and limit freedom of movement.”

- Vyacheslav Igorevich, 52 years old : “I serve in the Ministry of Emergency Situations and not so long ago our standard winter uniform was changed to a new one. The old one was sewn on batting, the received samples were sewn using modern membranes. If we talk about the ability to retain heat, it is almost identical. But the new products are much lighter and more convenient.”

Batting is a fabric that has proven its effectiveness over long periods of use . This is an inexpensive and warm material that continues to be in demand. But, it is gradually being replaced by more modern and lighter analogues.

In conclusion, we invite you to watch a short video on how batting is made:

Batting is insulation that will prevent you from freezing

As a rule, a good insulation for clothing should have several properties: it should be durable, retain heat and allow the body to breathe. Non-woven fabric undoubtedly has all these advantages. It is very soft to the touch and quite warm. The composition includes only natural materials that allow the batting to “breathe”. It very rarely causes allergies in people.

Batting also differs in the following parameters.

- By density . This is the most important characteristic of the material. The scope of its application depends on it. The density of products varies from 90 g/m to 1000 g/m. However, the most used materials have indicator values of -200-400 g/m.

- By composition .

- The most expensive fabrics are made from natural raw materials.

- 100% cotton. Wear-resistant and durable, they are easier to sew.

- 100% wool. The most expensive ones are made from excellent, non-flammable yarn. They are heavier and thinner than cotton, absorb moisture well and have excellent heat resistance.

- Cheaper products are made from viscose or polyester fibers. They are characterized by low creasing and wear resistance.

- Linen batting is well known to builders. It is made from short fibers – the so-called “shake” – waste from flax spinning.

- The most popular and in demand is wool blend material, which contains 30% wool and 70% cotton, viscose or synthetics.

- By color . Cotton fabrics are usually white, yellowish or light gray. Woolen ones are gray, they have the color of undyed wool. If the fabric is made from the remains of colored yarn, it is variegated.

- By thickness . Products are available in thicknesses from 3 to 12 mm.

Properties and Features

Batting has many desirable qualities.

- This is quite warm and reliable material.

- The products are distinguished by high noise-absorbing properties.

- Environmental friendliness and safety . The material easily absorbs and evaporates moisture and allows air to pass through well. Its safety is evidenced by the fact that according to GOST requirements, the use of batting is mandatory for mattresses for a crib.

- Negative characteristics include weight. Batting is a relatively heavy fabric even in dry weather. At high humidity, it can quickly absorb water and become even heavier.

- It should be remembered that over time it rolls off and forms sparse areas in the insulation.

- Wool batting can harbor moths.

Shelter

- Electra (Moscow)

Production: Podolsk, Moscow region.

Shelter insulation makes clothing warm, comfortable and does not restrict movement. Shelter insulation takes up minimal volume and is light weight. All this allows clothes to “breathe” even under heavy loads.

Shelter is hypoallergenic and absolutely safe for health.

Another property of clothing with Shelter insulation is its ability to shrink when folded and return to its shape when unfolded. This transformation is explained by the special structure of the insulation. Shelter consists of individual fibers that repel each other, but under pressure they are able to press tightly against each other.

Why do you need batting?

The use of batting is due to its good performance qualities:

- high thermal insulation for both low and high temperatures;

- ability to absorb noise;

- environmental friendliness.

Batting is an insulation material that is used as insulation for work clothes: it allows air to pass through well and retains heat well. Using batting as a lining for workwear allows you to create suits and jackets for working in cold conditions.

The main disadvantage of batting is its heavy weight (the most popular types of this material have a density of 200-400 g/sq. meter). The ability to absorb moisture well could be considered an advantage, but a wet cotton layer becomes very heavy and dries with great difficulty. In addition, the fibers in it roll down and are distributed unevenly over time, and the wool insulating layer contributes to the appearance of moths.

Although this non-woven material is used quite rarely in ordinary wardrobes, it is widely used for economic and technical purposes. The ability of this textile to withstand cold and hot temperatures has found wide application in various fields. Its excellent heat-insulating and noise-absorbing properties are irreplaceable in the manufacture of:

- Workwear and equipment for extreme weather conditions ( jackets , overalls , trousers , mittens, balaclavas, sleeping bags ) - batting is used to insulate clothing for those working in extreme weather situations: miners, oil and gas producers. It is used to make quilted jackets and sleeping bags , warm mittens and balaclavas, quilted overalls , pants and jackets :

- Various household and household appliances (pot holders, soft insulating upholstery). The fabric is good in the production of soft toys, packaging and shoes. It is used to cover ironing boards and stuff upholstered furniture :

- Bedding (cotton mattresses and pillows are recommended for children's and medical institutions) - batting is used in the manufacture of spring and orthopedic mattresses; it is used to fill blankets and pillows .

- Linen wool is used in construction for thermal and noise insulation of houses, as a gasket for floor coverings.

In addition, it is used in the manufacture of mattresses and furniture. In mattresses, this material is used as the topmost layer before covering. This makes it soft and very warm. Many buyers are looking for mattresses with batting filler. Sellers can talk for hours about what kind of filler this is.

Non-woven fabric is widely used in the manufacture of pillows and blankets. The important thing is that since it breathes well, the human body does not sweat. This material is also used for industrial purposes. Doors are insulated with batting pads, which can significantly increase their thermal insulation properties. In addition, this material is also used in automobile production.

In many stores you can find warm coats and jackets insulated with material such as batting.

Many people know what kind of insulation this is and therefore the demand for such things is quite high.

Thinsulate

- useYierman, RC(Romance)

Thinsulate – insulation made from Thinsulate – the highest protection against cold. It is considered one of the best insulation materials at the moment. In terms of its heat-saving properties, it is equal to down. It consists of very thin fibers that retain heat excellently. Insulated raincoats and jackets natinsuleyte - light, thin and warm.

Thinsulate does not deform when washed and is able to warm you in severe frosts. Natinsulate clothes are made for athletes, climbers, oil workers and other people working in the Far North.

Even in conditions of high humidity, Thinsulate insulation retains heat well. Thinsulate insulation fibers absorb little moisture, so the insulation works just as effectively in a humid environment, and dries quickly when wet.

Typically, clothing made from Thinsulate is not cheap.

Initially, the development was carried out to solve the problem of insulating the suits and shoes of astronauts. Having successfully solved this problem, the material began to be used for the production of all types of clothing.

Disadvantages of such material

While batting has many advantages, there are also certain disadvantages. This primarily applies to fabrics with a high content of wool and cotton wool. This material is quite heavy, and since it also has hygroscopic properties (it absorbs moisture well), when water gets on it, it becomes much heavier. Cheap batting sheets also tend to pill and fray in some places, so the service life of products made from such raw materials will not exceed four years. High-quality and expensive batting, the photo of which is provided below, can retain its good appearance even after ten years of use.

Climate Comfort System

What is Climate Comfort System?

Climate Comfort System is a symbiosis of innovative technologies, including:

“Comfortemp” is the latest development of the German company Freudenberg, created on the basis of NASA technologies specifically to protect the spacesuits of American astronauts from contrasting temperature changes. “Comfortemp” is a non-woven material consisting of paraffin microcapsules (PCM), which has the property of taking away part of the heat when a person is hot and giving it back when it’s cold. Located in the chest area of the back.

What is better padding polyester or batting?

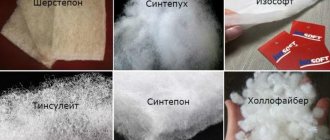

Modern technologies for the production of non-woven insulating materials often give preference to synthetics. The most famous among them is padding polyester - a layer of polyester fibers that can be attached to fabric or thermally stitched.

Often on sale you can see padding polyester sewn onto lining fabric - it is called synthetic batting, and, unlike real batting, it looks much more attractive thanks to the shiny lining fabric, figured stitching, and greater softness.

The main advantage that padding polyester over non-woven material made from cotton or wool is its low weight (about 100 g/sq. meter). However, synthetic fibers retain heat much worse, and such clothes will only be comfortable down to a temperature of -5 degrees.

For winter clothing, padding polyester has to be laid in two or three layers, and the advantage of its low weight disappears, but it does not absorb moisture, washes better and dries quickly. However, it should be remembered that synthetic winterizer is not suitable for work clothes, especially when there is a high possibility of contact with chemicals, sparks, or open fire; in these cases, a wool insulating layer is best suited.

Fibertek

- insulation production Belarus Elema, Bugalux

Fiberteck is an environmentally friendly material made from the finest hollow polyester fibers.

Insulation fibertek is manufactured in the Republic of Belarus by the JLLC “Trading House “Faybertek” in Zhodino (Minsk region)

Fibertek insulation represents the optimal ratio of the number of fibers and air per unit volume, at which the thermal conductivity coefficient of the material differs from air by only 19%.

Fibertek is a non-woven material, which is a bulk layer of a composition of the finest hollow polyester fibers, specially treated with silicone.

Thanks to this treatment, slippery silicone fibers move independently of each other, which is why the insulation does not get confused, does not cake and retains its shape even after getting wet.

To achieve the required strength and stability, the surface of the insulation is reinforced with polypropylene fabric and mechanically quilted.

All this prevents the migration of fibers to the outer surface of the product. Even after repeated washings, the insulation does not bunch up.

Elastic and durable non-woven materials provide fibertek insulation with the ability to withstand high tensile loads. This is especially important when the product gets wet and becomes heavy, when other materials similar in manufacturing technology, unable to withstand breaking loads, bunch up into a lump.

Fibertek is an environmentally friendly and non-toxic insulation material.

Advantages of fibertek insulation:

- perfectly retains its shape and restores it after deformation or washing;

- moisture-resistant, allows repeated washing and drying;

- provides a greater heat-protective effect compared to other materials of similar thickness and density;

- does not absorb odors and does not cause an allergic reaction;

- stable during long-term use;

- is environmentally friendly and non-toxic;

- Practical value for money.

Caring for products with batting

Materials with batting should not be machine washed. It is best to dry the batting in the fresh air, since it takes quite a long time to dry. This is explained by the fact that it absorbs moisture very well. This material should be ironed very carefully and only at a low temperature. Although batting is considered fire-resistant, it can become deformed at high temperatures.

Depending on the quality of the non-woven insulating material, it can last quite a long time, although it is better to update cotton mattresses and pillows at least every 7 years.

With prolonged use, their density may become uneven. This can be corrected by ripping out the cover , then manually redistributing and quilting the insulating layer.

If necessary, batting products can be washed, making sure first that the non-woven material does not fade.

Washing is done by hand, then the water is allowed to drain, the product is blotted with a towel and allowed to dry completely - this may take a lot of time.

What you should know about care:

- It is recommended to wash clothes containing batting by hand with regular powder or gel. In this case, you should pay attention to the color of the insulation and covering fabric. If the batting is darker, it may stain light-colored material when washed. In this case, it is better to take the item to dry cleaning.

- To avoid streaks after washing, hang the new product on hangers, wait until the water drains, after which it is blotted with a dry terry towel.

- Things with experience may have sparse places in the insulation. They are dried in a horizontal position and hung on hangers slightly damp.

Pooh

- for the raincoat range from Clasna, Desentry, Linora

Down is one of the natural insulation materials and is the most popular because its lightness and thermal insulation are at a high level. The insulation contains up to 70% down and 30% feather. The feather is necessary to distribute the fluff evenly throughout the product.

A complete replacement for down is not expected in the near future. The main advantage of down is its extremely high thermal insulation. In terms of this indicator, high-quality down is approximately twice as good as the best synthetic analogues. When used properly, down also demonstrates amazing durability.

Down does not remove evaporation well and therefore does not “breathe”. In this regard, it is not recommended to use down products under severe physical activity and/or at insufficiently low temperatures. Evaporation from the body will moisten the down, and getting it wet will lead to a loss of thermal insulation properties. Down clothing is absolutely unacceptable in conditions of high humidity.

In addition, fluff is prone to migration through the fabric and seams of the product. To combat migration, special down-containing calendered membrane fabrics are used. Much attention is paid to the design of the down bag. Recently, products with seamless assembly have begun to appear, which makes the migration of fluff to the surface almost impossible.

About the terms of use

- Depending on the thickness, density and nature of use of the products, the material can serve flawlessly for different periods of time. A mattress, pillow or blanket can look decent even after 10 years. However, experts recommend changing bedding at least once every 5-7 years.

Of course, today this non-woven material is not as popular as it was in the last century. It is being replaced by modern, high-tech fabrics. But there are still areas of application where brilliance and showiness are forced to give way to practicality, reliability and cheapness. Batting continues to be the most popular utility and technical fabric today.

Local Thermo

What is LOCAL THERMO zonal insulation?

LOCAL THERMO is a system of internal thermal insulation of a jacket, built according to the zonal principle.

Not all parts of the human body emit the same amount of heat; they react differently to the ambient temperature, therefore, they need to be insulated in different ways. The shoulder area needs maximum insulation; a special foil insulation is used here - heat-reflecting Valtherm, which directs heat inside the jacket.

LOCAL THERMO is a guarantee of zonal thermal protection.

“Local Thermo” is a system of internal thermal insulation of the jacket, built according to the zonal principle. Not all parts of the human body emit the same amount of heat; they react differently to the ambient temperature, therefore, they need to be insulated differently. The shoulder area requires maximum insulation; a special foil insulation is used here - heat-reflecting Valtherm, which directs heat inside the jacket.