Home / Fillers

Back

Published: 06/16/2021

Reading time: 3 min

0

8

The requirements for modern winter clothing are simple. It should be warm, yet weightless and comfortable. It would seem that these characteristics are difficult to combine in one coat or jacket. But with the latest synthetic material, such as isosoft insulation, everything is possible. Read more about its properties, what weather it is designed for, and how to care for it.

- 1 Production and characteristics of the material

- 2 Types of density and temperature conditions

- 3 Advantages and disadvantages

- 4 Caring for clothes with this filler

- 5 Reviews about product quality

- 6 Conclusion

Production and material characteristics

Isosoft insulation is an innovative non-woven product from the Belgian company Libeltex. The structure is twisted polyester threads. Sometimes they are so twisted that they look like microballs. Thanks to such a springy structure, the item fits the body, taking on its contours.

The outer layer of insulation consists of a two-layer silicone polymer coating. Thanks to the heat-sealed surface, the fibers do not move and cold air does not get under the clothes. The insulation has pores to evaporate excess moisture, thereby eliminating the “thermos effect”.

What is isosoft made of?

The insulation was invented and introduced into their own production by specialists from the Libeltex company, which has been manufacturing non-woven fabrics for filters for more than half a century. After merging with the British Vita Group, a company specializing in the production of polymer fibers, Libeltex began producing filter sheets from thermally bonded fiber components for sensitive self-healing filters. A logical continuation of the developments was the creation of isosoft insulation, the composition and structure of which is patented.

It is known that the material is made from fine-denie hollow fibers. These are high metric number products. The number in the fiber characteristics characterizes its fineness. The number is obtained by dividing the length by the mass. Usually the numbers indicate the length of the fiber or thread weighing 1 gram. Thin fibrous products are characterized by large numbers.

Soft and lightweight material

The basis of the hollow structures is a polyester polymer. In some modifications, the fibers are additionally siliconized. In this case, hollow, highly crowded polyester fibrous structures are additionally coated with organosilicon polymers to improve heat-insulating properties. The degree of twist can be so great that the fibers form a spherical shape. These types of insulation are especially good for the production of sleeping accessories: blankets, pillows, sleeping bags. The springy structure helps fit the body while sleeping. The products take on a form that is comfortable for humans.

Types of density and temperature conditions

To ensure that the isosoft filler has the widest possible scope of application, the manufacturer has created insulation options that differ in their density. Their main types, intended for certain weather conditions, are presented in the table below:

| Harsh winter | Late fall | Demi-season models |

| from 250 to 300 (g/m2) | from 100 to 160 (g/m2) | from 50 to 75 (g/m2) |

Isosoft insulation for clothing assumes a wide temperature range of use of about 40 degrees: ─30°C ... +10°C.

According to another classification, the following types of isosoft are distinguished:

- Category 103, which is based on the finest fibers. Differs in plasticity. The moisture-repellent composition protects the canvas on both sides. It can be 3─25 mm thick. Requires quilting.

- Modification marked 34. Based on siliconized hollow polyester threads. The material has a thickness of 4─15 mm. The insulation fibers are protected by polymer. No quilting required.

- Product 304 6─22 mm thick. Quilting is not necessary for jackets, but it is required for coats.

Isosoft 101 ─ material for insulating travel equipment and bedding. It is characterized by strong twisting of polyester fibers and elasticity.

Special insulation from Belgian manufacturers

Isosoft filler for sleeping bags and blankets

To fill sleeping bags, a special material is made - isosoft 101. The degree of twisting of the fibers is so great that they curl into spirals. Tangles of spirals form spherical structures that perfectly fill space, absorb physical stress from the body of a sleeping person, and take a comfortable shape.

The company produces several other types of specialty products. They have a different fiber composition and are not classified as isosoft.

Advantages and disadvantages

First, about the advantages of the product. Isosoft insulation for clothing:

- allows air to pass through well, that is, “breathes”;

- excellent heat insulator;

- 5 times thinner compared to padding polyester;

- lightweight, therefore used in clothing for children;

- soft, elastic;

- hypoallergenic, does not create an environment favorable for the proliferation of pathogenic bacteria, fungi, and dust mites;

- wear-resistant;

- fibers do not “bleed” through the lining and main fabric. Thanks to this, isosoft combines well with many materials;

- dries quickly;

- Versatile, can be worn in any weather.

The advantages of isosoft have been duly appreciated by clothing manufacturers for both adults and children. Now you don’t have to dress your child in a heavy fur coat. Jackets and overalls with isosoft do not restrict movement. You can play sports in them without getting cold or sweating.

Isosoft has one minus - its high cost. It was this that became the reason for the low prevalence of high-quality insulation.

Which one to choose?

When purchasing warm clothes, you need to imagine the properties of their insulation. In addition, it is important to know how long it will last and what problems you may encounter during operation.

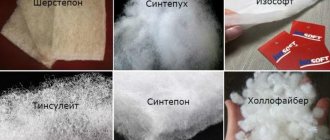

Sintepon

Lightweight, voluminous, inexpensive material for many years was the only synthetic insulation for winter and demi-season items. It is made from polyester fibers in two ways: by gluing the fibers or by heat sealing. The first method produces a non-ecological product, while the second produces a short-lived product. Sintepon is 4 times thicker than Isosoft, loses volume after washing, and quickly falls off. In addition, the body in synthetic clothing does not breathe, outer clothing does not retain its heat. It is not suitable for severe frosts.

Thinsulate

The warmest and most expensive synthetic material. Its structure consists of extremely thin fibers. When creating Thinsulate, American scientists tried to replicate the design of the best down of the northernmost duck - the eider. The resulting insulation surpassed the natural original. Thinsulate is 1.5 times warmer than natural down. Thin, flexible, lightweight material is used to make not only suits for extreme professions - astronauts or polar explorers. It makes wonderful fashionable clothes. Thinsulate has a three-dimensional fiber configuration, it quickly restores its shape and does not deform when washed. This is the only synthetic material that can withstand machine washing at 400C and spinning at 1000 rpm.

Holofiber

This patented trademark is essentially a type of padding polyester, but differs from the latter in its excellent consumer characteristics. Holofiber insulation provides warmth at air temperatures down to -25°C. It is environmentally friendly, has low density and light weight. It holds its shape well, but is slightly flexible. It is suitable for sewing sportswear, but it is unlikely to make a fashion item. All characteristics are similar to Isosoft, but differ from it in lower cost.

Goose down

In terms of heat-protective properties, this insulation is close to Isosoft, but it belongs to natural materials. Down fibers are extremely mobile relative to each other. This causes difficulties when washing and drying. The down filling absorbs moisture, and in humid weather it becomes heavier and does not warm well. In addition, natural material can become a breeding ground for mites and cause an allergic reaction.

Caring for clothes with this filler

The care rules are the simplest. They are described in detail on the label of the jacket, coat or overalls. A set of standard recommendations:

- A jacket insulated with isosoft should be washed separately from other clothes. This can be done many times, both in a machine and manually, but at temperatures up to 40°C.

- The use of bleaches, especially chlorine-containing ones, is contraindicated. Liquid detergents are recommended for their ability to quickly rinse out of the fiber structure.

- When washing by hand, avoid rubbing and twisting the products so as not to damage the insulation fibers.

- Rinse until clean.

- Soaking is not recommended.

- When washing automatically, select the “delicate” wash program without the “drying” function, but with an additional rinse.

- Spin at minimum speed.

- Dry by hanging vertically, away from direct heat. A well-ventilated room or balcony is suitable for this. Dry filler easily takes its original shape.

- If streaks appear, wash the jacket again, but without detergents.

- Dry cleaning possible.

- Ironing is not recommended.

Advice! When washing automatically, use a special bag or a clean pillowcase. If there are greasy stains, first treat the stains with a soap solution. Before use, it is advisable to test in an inconspicuous place.

Store rolled up. When untwisted, the shape of the products is quickly restored.

Author:

Zakharova Nina Afanasyevna

I hope you like my article! If you find any shortcomings, just write to me about it! I am always ready for a conversation and will answer any questions you have, ask them!