Synthetic fibers

- fibers obtained by synthesizing polymers consisting of natural low-molecular substances (C, H, O, N, etc.) as a result of polymerization or polycondensation reactions. Polymers are synthesized from oil, gas and coal processing products (benzene, phenol, ethylene, acetylene, ammonia, hydrocyanic acid), which are produced in huge quantities at chemical plants. By changing the composition of the starting products, it is possible to vary the structure and properties of synthetic polymers and the fibers obtained from them.

The most common among them: polyamide (nylon, nylon, dederon, silon, perlon), polyester (polyester, lavsan, dacron, vicron, polyester), polyacrylonitrile (acrylic, nitron, curtel, orlon, dralon, cashmilon), polyurethane (elastane, spandex) etc.

Polyurethane compounds

Man-made fibers are in demand in the textile market. Several thousand types of them are known in industry. They are used for the manufacture of workwear and sports suits. Polyurethane threads have mechanical properties characteristic of rubber:

- high elasticity;

- reversible deformation.

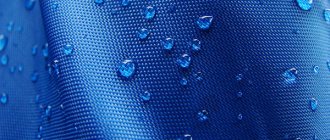

Fabrics made from polyurethane raw materials are elastic, abrasion-resistant, elastic, and wrinkle-resistant. Fibers are rarely used in their pure form. They have found application in the textile industry as gimp threads. Their disadvantage is low thermal stability. At a temperature of +120 ℃, strength decreases.

Examples of man-made polyurethane fibers:

- elastane;

- spandex;

- neolan.

Yarn with synthetic fibers:

- Annie Blatt - Victoria (France)

- Annie Blatt - Domino (France)

- Annie Blatt - Merino (France)

- Annie Blatt - Muguet (France)

- Annie Blatt - Sequins (France)

- Annie Blatt - Jeeps (France)

- Annie Blatt - Gypsum Cocktail (France)

- Mondial - Merino Extra (Italy)

- Ramsden - Peter Pan (England)

- Ramsden - Peter Pan Print (England)

- Ramsden - Cupcake (England)

- Ramsden - Robin (England)

- Filatura di Crossa - Knight (Italy)

- Filatura di Crossa - New Tuxedo (Italy)

- Filatura di Crossa - Scherzo (Italy)

- Louise Harding - Marletto (USA)

- Shulana - Baloma (Switzerland)

- Madeira - Jabara (Germany)

- Madeira - Lame (Germany)

Polyamide threads

Plant and animal polyamide fibers are abrasion resistant. They have high dimensional stability. Their disadvantage is their low resistance to light and sweating. When exposed to sunlight, polyamide fibers turn yellow and become brittle.

Low hygroscopicity and a high probability of being subject to strong pilling are a feature of the threads. To improve performance properties, stabilizers are used in chemistry. In industry, polyamide fibers are added to cotton, wool, and viscose.

Finished textile products have good hygienic and mechanical properties. Raw materials can be in knitwear, hosiery, sewing thread and haberdashery. The polyamide type includes nylon, nylon, meryl, enanth.

What raw materials are used

The raw materials for production are waste from the processing of fossil hydrocarbons - oil, coal, gas. The resulting phenol, benzene or ethanol is exposed to altered conditions of pressure, temperature or hydration, and after adding reagents, a mass is obtained from which polymer strands are drawn. The threads are brought to the required density, then they are woven into fabrics.

The production of chemical fibers is toxic, so it is recommended to first rinse the product in plenty of warm water, and only then wear it.

Polyester compounds

Polyester threads have increased heat resistance, exceeding the values of long and short fibers. Due to good elasticity and high abrasion resistance, the raw material is widely used in industry. Fabrics made from polyester threads hold their shape, do not require ironing, and do not wrinkle. They are characterized by high physical and mechanical properties.

Disadvantages of the polyester type:

- tendency to peel;

- electrification;

- slight hygroscopicity;

- excessive rigidity.

To eliminate the disadvantages, the feedstock is modified. Polyester fibers are combined with cotton and wool. In combination with viscose threads, dress, shirt, coat fabrics, and faux fur are produced.

Modification of raw materials helps eliminate creasing. At the same time, abrasion resistance increases. The hygienic properties characteristic of primary raw materials are preserved after processing.

List of polyester threads:

- polyester;

- lavsan;

- terylene.

What is synthetics

While flax, wool, silk, cotton are the result of centuries of experience of farmers and livestock breeders, synthetic fiber is the triumph of the human mind. Everything that is commonly called synthetics is obtained - that is, synthesized, as the head of DuPont aptly described it, from “coal, air and water.”

It would seem that there are three components! But the list of synthetic fabrics has long exceeded a hundred, and is constantly updated with new items, specially created for a specific task.

Despite the fact that synthetics is a little derogatory, it has firmly entered the life of a modern person, making it comfortable due to its properties.

Polyacrylonitrile components

Polyacrylonitrile components have mechanical properties like artificial wool: strength, high light fastness, heat resistance. The product, made from polyacrylonitrile threads, holds its shape well. Disadvantages of the type:

- low hygroscopicity;

- risk of pill formation;

- electrification;

- rigidity.

To eliminate the shortcomings, modifications are carried out. In textile factories, the technique is used when sewing outerwear. Experts combine polyacrylonitrile threads with wool and faux fur. The group includes the following fibers:

- acrylic;

- nitron;

- Cashmilon.

Product care

- Wash products made from synthetic fibers at a temperature of 30-40 degrees. Polyester - up to 60 degrees. For white items, universal powders are used; for colored items, special powders are used for thin and colored fabrics. You can choose any washing mode depending on the degree of contamination and type of fabric. You can spin it in a washing machine, reduce the number of revolutions to a minimum.

- Such products cannot be dried in the machine, since the resulting wrinkles will then be very difficult to smooth out. Drying outdoors or in a well-ventilated area is preferable. It is forbidden to dry synthetics on radiators.

- Iron synthetics using the “silk” setting. Nylon is ironed at a minimum temperature without wetting.

Publications on synthetic fabrics

Polyolefin category

This group includes polypropylene and polyethylene threads. They are characterized by low density and lightness, zero hygroscopicity. Due to the latter property, the fibers do not sink in water, but have high thermal insulation. Their disadvantage is their low heat resistance - +115 ℃. In response to its leveling, a modification is made.

The optimal solution is to create a two-layer material, in which the bottom layer is made of polyolefin threads, and the top layer is made of hygroscopic cellulose raw materials. This technology prevents the bottom layer from getting wet. Moisture is removed into the hygroscopic top layer.

This modification is effective for sewing underwear, stockings, socks, tracksuits and other products with high hygienic characteristics. The polyolefin group includes:

- found;

- herculon;

- Ulstren;

- meraclon.

Polyethylene threads are used for technical purposes. The subcategory includes tekmilon, dyneema, spectrum.

Story

The history of mankind is a constant struggle to improve the quality of life, including for affordable clothing for the season, for the opportunity to have several sets of underwear, and not wear the same dress for decades.

Silks, satin or brocade have always been very expensive, available only to the nobility. For example, in the wardrobe of the famous spender and the main shopaholic of her time, Empress Elizabeth Petrovna, a little more than 3,700 dresses remained after her death. The Empress, after 20 years on the throne and 52 years of life. But dresses weren’t thrown away in those days!

The issue was resolved when chemical fibers were invented, which produced durable, cheap materials. In particular, synthetic fabric.

It all started with America and the DuPont company, which is still the world leader in the chemical industry. At the beginning of the 20th century, DuPont specialists worked on the creation of chemical warfare agents (for example, hydrocyanic acid), developed means for the US Army to protect against enemy gas attacks, and reagents for the decontamination of contaminated areas and surfaces.

At the same time, DuPont conducted research in dozens of its own laboratories, the results of which it also hoped to use to strengthen the military power of its country.

Doctor of organic chemistry Wallace Carothers worked in one of these laboratories in Delaware since the late 20s. It was his team that created the artificial rubber known as neoprene and synthesized polyester for the first time. However, a historical breakthrough was the invention of an inexpensive polymer with outstanding performance characteristics, which was called “nylon.”

This was the golden time of synthetics: the first few months after entering the market, nylon stockings cost twice as much as silk stockings, and they were sold out instantly.

Thanks to nylon, World War II cost the United States much less, because it was used for sewing parachutes, in the manufacture of awnings, tents and even car tires. There was also a political moment: new inventions saved America from its dependence on the Old World for raw materials. Cotton, jute, and hemp for military needs were successfully replaced by nylon, rubber by neoprene, and tarpaulins began to be made from polyester compositions.

The need for raw materials for industrial development stimulated oil production and economic growth in the Midwestern states, launching the development of the mineral fertilizer sector. Having entered the war, the US government planned to finally deal with the consequences of the Great Depression and restart the economy. They succeeded.

After the victory, military developments were gradually reoriented towards light industry. The era of synthetics has begun.

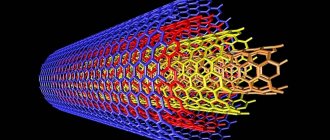

Fiber classification

They differ in chemical composition:

- Heterochain

fibers - in macromolecules they contain, in addition to carbon, other elements (N, O, S). They are produced from resin melts, so they do not decompose when melted during operation. Stretching is possible at normal temperature. Typically used for industrial and household woven products.

- Carbon chain

fibers - contain exclusively carbon (C) in the molecules of the main chain. They are usually produced from acetone solutions and saturated gels. The exception is full-lefin formulations. Stretching is carried out at a temperature of 100°C. Most often used for the manufacture of monolithic parts.

Advantages and disadvantages

Synthetic fabrics have a number of undeniable advantages, the main ones being accessibility and low cost. They are easy to care for and easy to transport.

However, there are disadvantages common to synthetic textiles:

| Description | |

| Disadvantage #1 | Too electrified |

| Disadvantage #2 | Not hygroscopic |

| Disadvantage #3 | Poorly ventilated, creates a “steam room” effect |

| Disadvantage #4 | Absorbs fat and is difficult to remove |

| Disadvantage #5 | Not heat resistant |

| Disadvantage #6 | A hot iron causes the color of the fabric to lose its brightness. |

Synthetic clothing is not suitable for people with sensitive skin; it is not recommended for those suffering from skin and autoimmune diseases, allergies, asthmatics, pregnant women and small children.

Selection rules

You need to choose synthetic fabrics taking into account future use, as they are often made for specific conditions. In order not to make a mistake, you need to carefully read the accompanying documents or, in the case of a finished product, the label.

The production of chemical fibers is toxic. Despite multiple cleaning steps, there is a possibility that volatile substances will not be removed. Therefore, you should not take 100% synthetics for daily use, 30% is the maximum, which will not cause discomfort.