What is suede

Suede is a material produced by tanning the skins of small animals. Suede has no face, soft, thin and velvety on both sides. Due to the unique characteristics of strength and at the same time elasticity, suede is used to make clothes, shoes and other products.

An interesting fact is that initially suede was thick, as it was created from the skins of cattle, and only over time it began to be made from the skins of small livestock.

A little about the name

The Russian word “suede” comes from the Polish “zamsh”, which is derived from the German “zamish”. The latter, in turn, comes from the French word for chamois. It was this animal that gave the name to the material in many European languages.

Departing from the main topic, it is worth mentioning the frequently arising question of declension of the name of the material - suede or suede. The correct one is the last option. Under no circumstances can the name "suede" be converted into "zamsh" - such a word does not exist in the Russian language.

The history of suede

Animal skins began to be used in the production of materials back in the 9th century. Then it was treated with various fat-containing products to improve its performance properties. After about nine centuries, fish oil and various plant mixtures began to be used to soften the skin. The technology gained popularity and reached Russia. Here, suede gained particular popularity in Nizhny Novgorod and Arkhangelsk, where tanners were called ireshniks (from the word “irha” - suede), and the process itself was “fleshed” or “vezhit”. Suede began to be produced on a commercial scale only in the 19th century.

Production technology

The process of sueding natural leather using tanning substances helps give suede strength, ductility, softness and velvety. The production of suede fabrics is divided into several stages:

- Preparing skins with pre-haired skins.

- Skinning is the removal of the dense top layer.

- Treating the hide with formaldehyde.

- Applying seal, cod, whale oil or a vegetable mixture to the cleaned skin.

- Placing the fabric in special impact grinders, where the fat is absorbed into the fibers.

- The skins are folded and heated.

- The fatliquoring procedure is repeated, if necessary, several times.

- Degreasing the canvas in a potash solution.

- If necessary, the material is treated with abrasive for greater hairiness.

- The canvas is painted. Since it is initially brown in color.

Manufacturing stages

The production of natural suede is a rather complex and labor-intensive process. It is carried out in stages:

- The natural skin of the animal is prepared for production - cleaned of wool, etc.

- The prepared canvas is lubricated with fat of animal or vegetable origin.

- The fat-treated canvas is placed under impact grinders for several hours. This allows the skin to become saturated with oil from the inside.

- As a result of impregnation, a combination of fat and protein is formed - the oxidation process begins.

- The processed skins are folded, heated, oiled again and placed again under the grinders - the material goes through this stage several times in a circle.

- After repeated treatments, the material no longer heats up, it becomes soft and acquires a yellow-brown tint.

- The resulting material is degreased with a special solution, thanks to which after some time the canvas becomes waterproof.

- The finished material is painted. This is the last stage.

The material is ready - now you can sew various products from it.

Properties of natural suede

Due to its natural origin, suede is considered a hypoallergenic and wear-resistant material. High-quality suede products last a long time, do not accumulate static electricity, allow air to pass through well and do not fade over time. The material is resistant to deformation and moisture.

What does the fabric look like?

Externally, the material looks elegant and noble. The soft and uniform velvety surface is pleasant to the touch. The fabric can be thin, which means it fits well and fits in beautiful neat folds, or thick, which means it can be denser and more shaped.

Does suede stretch or not?

Compared to genuine leather, suede is a more pliable and soft fabric. Thanks to its elastic properties, suede shoes break in well and fit perfectly on the foot. However, if the selected suede shoes or boots are short in length, tight, or do not fit well, it is not recommended to buy such products. If you experience only slight discomfort after buying new shoes, you can get rid of it at home using a special shoe stretcher.

Cost of suede

Artificial material costs 300–500 rubles per meter. Alcantara for car covers can be purchased for 400–600 rubles per meter. Natural fabric is more expensive - from 1000 rubles per meter. You can buy fabric in specialized stores or online.

The cost of suede items also depends on the origin of the material. A faux suede bag costs 1,500–2,000 rubles. Natural suede jacket - about 10,000 rubles.

Bags, backpacks, and wallets made of eco-suede can be purchased in online stores. The Ecology Light store offers items made from environmentally friendly fabrics at attractive prices.

Pros and cons of natural suede

Like any other material, suede has advantages and disadvantages.

Advantages of natural suede:

- Aesthetic appearance. Suede items look chic, but at the same time neat and noble.

- Long service life. If you properly care for the material, it will remain in its original form for a long time. Even abrasions and small defects will not spoil the quality of the canvas.

- Thermal insulation properties. The fabric retains heat well in winter and cool in summer, so it is indispensable in the production of clothing and footwear.

- Comfort. Suede clothes are very comfortable. The material does not restrict movement, is very pleasant to the body and allows the skin to breathe.

- Compliance. The elastic properties of suede help fabrics stretch and quickly restore their original shape.

- Antistatic and hypoallergenic. Due to its natural nature, suede does not accumulate static electricity and does not cause allergic reactions.

Despite the many advantages, the material also has disadvantages:

- Absorbs moisture. This affects the comfortable wearing of clothes and shoes and their aesthetic appearance, since the material, together with moisture, attracts dirt and takes a long time to dry.

- Instability to mechanical stress. The material is quite easy to tear.

- Difficulty of care. Suede items require delicate handling, dry cleaning and additional procedures to preserve their appearance.

- High price. Compared to artificial analogues, natural suede is more expensive.

Sometimes suede manufacturers coat their fabrics with special compounds to reduce the risk of damage.

The main differences between fabrics and how to spot a fake

One of the main criteria for choosing a suitable item is its authenticity. Now the technology for producing artificial suede is so advanced that not everyone can distinguish between these options. The main criteria that you should focus on when buying suede items are described below.

How to distinguish suede from artificial material:

- Price. High-quality leather simply cannot be cheap. This is especially true for exclusive items from well-known manufacturers.

- Appearance . Natural suede has some disadvantages: a slightly porous structure, variations in color and uneven surface. Naturally, such defects are not noticeable, but upon careful inspection you can notice them.

- Smell. The spicy aroma of real leather is difficult to confuse with something else, so don’t be shy to smell the chosen item.

- Pile direction. One of the most characteristic indicators can be checked by simply moving your fingers. If the pile changes color in the direction of movement, then you are lucky to be dealing with natural suede.

- Water test. When you apply a drop of water to natural suede, it will be absorbed almost instantly. The drop will simply roll off the artificial analogue, leaving no visible traces.

- Fingerprint test. When you take a suede item in your hands, you don’t have to worry that noticeable marks will remain on it. On artificial material they will be more visible, quickly straightening with additional stroking.

- Touch test. Another interesting way is to pick up the item. Genuine leather will warm up to your body temperature almost instantly. Faux suede will remain cold during this time.

- Inner part. The reverse side of the selected item should have a characteristic structure. You are absolutely faced with a fake if it is made of fabric. No one will disguise natural suede in this way; on the contrary, manufacturers try to emphasize this nuance.

In order for a purchased pair of shoes or a favorite suede jacket to please its owners longer, special care conditions must be observed.

First of all, this applies to cleaning suede products. In especially difficult cases, it is better to use dry cleaning services, and to remove everyday dirt, be sure to purchase a line of specialized products. Brushes and erasers for removing dirt, as well as special impregnations and shampoos will extend the life of your favorite item.

Buying natural suede will not always be justified. Besides the cost, this may not be practical when it comes to some uses. Faux suede may be the best option, so the information below will be helpful.

The link describes Arben fabrics.

Kinds

In the range of textile products you can find several types of natural suede. Each of them has its own characteristics and properties.

By thickness

There are 2 types of material:

- Refined grade - has excellent breathability. Made from goat or deer skins.

- Unrefined variety - the fabric is denser and less elastic. Made from sheep and calf skins.

Double face double sided

The name “double face” means that the fabric has two front sides. Typically, such suede material has a velvety front and a fur base on the back. Double front suede is usually used for sewing warm outerwear and non-rough shoes.

Scuba

Suede on a scuba is a material consisting of 2 layers: artificial suede and knitted fabric. The fabric is more durable than natural suede, stretches well, is less sensitive to external influences and costs less. The material is easy to care for and can be used for sewing clothes and shoes.

Coasting

Natural suede treated with laser coating. This treatment reduces the traumatic nature of the material and the possibility of surface abrasion. Products made from rolled suede look more impressive due to their characteristic shine.

Synthetic

Made from synthetic polyester or microfiber fibers. Externally, synthetic suede is practically no different from natural one, but has additional advantages in the form of resistance to dirt and deformation.

Reinforced

Special suede cleaning wipes eliminate the use of household chemicals. The fabric consists of polyester fibers. It has a velvety surface that helps clean surfaces without streaks and additional effort.

Furniture

A dense synthetic material consisting of 100% polyester, which is used for upholstery. Outwardly, it strongly resembles suede, but is more resistant to mechanical stress, denser and more wear-resistant.

Artificial leather: how it differs from real leather, its properties

Making faux suede also requires utmost care. There are two varieties of this fabric. The first is obtained by gluing small fibers onto a solid base. This is the least strong and durable option. Such a surface is easy to damage, so this suede is considered not so popular, but very cheap.

Natural suede

The second type of artificial suede involves the process of creating fibers using looped threads. Subsequently, quite high-quality pile is made from them. Of course, this option is more preferable, especially since it has a lot of positive aspects of use.

Benefits of faux suede:

- Affordable price. This is the main advantage of this material, because not everyone can afford products made from natural suede.

- Excellent imitation . Sometimes it is not easy even for professionals to discern the unnatural nature of the origin of this skin.

- Ability to add additional properties . Many impregnations, for example, waterproof ones, are best suited for artificial suede.

- Less problematic care . Be sure to check this point before purchasing, but, as a rule, it is much easier to care for high-quality artificial suede than its natural counterpart.

Disadvantages include the inability to transfer heat. Faux suede products can make you feel cold, but in summer they are extremely hot. Faux suede is harder and has a shorter service life. Manufacturing technologies are constantly being improved, so it is worth paying attention to the durability of the coating, as well as the quality of the accessories used.

Tulle mesh with embroidery looks beautiful.

Names of all cotton fabrics: .

Read the instructions on how to attach a canopy to a crib.

Features of home care

Suede is a delicate material, so items made from it require special care.

How and with what to clean suede

To ensure that suede products last as long as possible, pay utmost attention to their careful cleaning and selection of products. Basic recommendations:

- Always treat items with a special aerosol for suede before first use;

- give preference to dry rather than wet cleaning;

- to remove stubborn stains, use a special rubber or silicone brush for suede;

- if wet processing cannot be avoided, choose only products for natural materials, and then dry the item in natural conditions, excluding the surface from exposure to sunlight or contact with heating devices.

How to wash suede items

It is recommended to wash items made from natural suede only in the most extreme cases. If you had to resort to this processing method, follow certain rules and nuances.

Handwash

Hand washing suede products is preferable to machine washing. However, to avoid damaging your clothes during hand washing:

- Do not pre-soak products;

- wash only in cold water;

- use only detergents for natural materials;

- do not make strong mechanical movements when processing;

- After washing, do not twist the product, let the water drain and gently pat dry with a towel.

Automatic wash

Washing in a washing machine is acceptable for faux suede and only in the most extreme cases. To process items, set the machine to delicate mode in cold water without spinning. Do not machine dry. After washing, hang the clothes over the bathtub, let the water drain and blot the material as it dries to avoid streaks.

How to remove stains

Remove stains carefully and carefully. Do not use aggressive or abrasive substances, as well as products containing acetone, chlorine or other acids. It’s better to use the materials at hand:

- for light suede, use a solution of milk and soda;

- You can remove fresh, light stains with a regular eraser;

- greasy traces from food are easily removed with a paste of starch and ammonia.

How to Clean Suede Gloves

Gloves are an elegant accessory. In order for them to retain their sophistication, the material must look neat and perfectly clean. Caring for suede gloves should be careful and regular:

- After purchase, treat the surface with a special impregnation. This will help maintain the appearance of the accessory for a long time.

- To remove dirt or greasy marks, hold the gloves over steam. This will help lift and fluff the pile. After this, scrub the surface with a special suede brush.

- You can remove stubborn stains by treating the products with a solution of 1 tbsp. spoons of ammonia and 5 tbsp. spoons of water.

- Wash gloves only when absolutely necessary in cold water with a suitable detergent, and be sure to wear them on your hands.

- After wet processing, be sure to wipe the surface of the material with a fleecy cloth.

- Dry items only at room conditions, away from sources of artificial heat.

How to care for outerwear

For outerwear, always try to dry clean. To remove stains, use the following methods:

- If there are stains of dirt on the surface, dry them and then scrub with a wire brush. After cleaning, lift the lint with a silicone brush.

- You can remove traces of products of plant and animal origin using talc. Simply sprinkle the dirt with the substance, leave for 3 hours, and then comb out the pile.

- A mixture of ammonia and water in proportions 1:4, purified gasoline or starch will help remove more persistent stains.

- To carry out a comprehensive cleaning, hold the product over steam and then carefully comb the pile with a silicone brush.

- If the dirt is so strong that wet cleaning cannot be avoided, use a mild soap solution. Apply the substance to a cotton sponge and rub. Remove the remaining foam with a damp cloth, only very quickly so that the water does not have time to penetrate deep into the fibers.

- If the above methods do not help, do not experiment and take the items to the dry cleaner.

How to clean suede shoes

Suede shoes require the utmost care and maintenance. Cleaning rules:

- Immediately after purchase, treat a pair of shoes with a protective agent for natural suede.

- If dirt gets on the surface, wait until it dries and wipe it off with a silicone brush. At the same time, make sure that the dirt does not dry out, otherwise it will be problematic to remove it.

- For comprehensive cleaning, use steam treatment. When the fibers are straightened, clean the surface with a special eraser or suede brush.

- You can clean light suede shoes using a special solution. Mix milk, talc, magnesium salt and turpentine in equal quantities and treat the stains with the mixture.

- If you wet your shoes and there are salt stains on the surface, use a 5% solution of table vinegar to remove them.

Can suede be ironed?

It is not recommended to iron suede, like smooth or any other leather. After hot exposure, the material may become deformed and lose its attractive appearance. Some housewives iron products through a layer of fabric at a minimum temperature. However, in this mode it is unlikely to get rid of wrinkles. You can smooth a thing made of natural suede using a steam generator or simply hanging it on a hanger over a bathtub with hot water.

Meaning of the word suede

(Sämischleder, peau chamoisée, chamois or oil-leather) and suede (Fettgerberei, chamoiserie, chamoising). — Leather is the name given to leather prepared by soaking raw hides that have been subjected to preliminary preparation with fat (see Tannery). To prepare food, lamb, goat, cow (also ox and buffalo) and deer skins and the skins of chamois, wild goats and antelopes are used. Z. is distinguished by its special softness, which it retains not only after soaking in water, but also after washing in soapy water, which is why Z. is also called “washable leather” (Washleder, washleather). When sueding, the fat that serves to saturate the leather undoubtedly undergoes a significant chemical change. The product of fat change produced by suede most likely enters into a chemical combination with the substance of the skin. Both conclusions follow from the following facts. Fat cannot be extracted from finished fat either by solutions of carbonic alkalis or by weak solutions of caustic alkalis. Cold water has no effect on Z.; water destroys glue only with prolonged boiling or heating under pressure, and a relatively small amount of glue is formed. The nature of the change in fat during suede and the essence of this process have not yet been completely studied. The external phenomena that accompany the change in fat during leather sueding are an increase in temperature during the process and a change in the color and smell of the leather. Considering the work methods used for suede leather, it is easy to notice their significant similarity with the work methods used to ferment various substances, observing the phenomena occurring during suede; one can also see their similarity with the phenomena that occur during certain types of fermentation. It is precisely the working methods for suede that are very similar to those that should be used to induce fermentation through aerobic microorganisms: during the period of reproduction of these microorganisms, it seems most convenient to bring them into direct contact with air, and during the period of fermentation, the environment in which these microorganisms are located, the presence air is not necessary to complete the process, and its progress depends mainly on temperature. When making suede, immediately after soaking in fat, it is necessary to bring the leather into as complete contact with air as possible, and to carry out the process of changing the fat itself, the presence of at least a large amount of air is not required, and the leather must be in such conditions that the temperature increases during the onset of the process. could be maintained for some time at a known boundary. Based on all that has been said, it can be assumed with high probability that the change in fats during suede of the skin occurs not simply from the action of atmospheric oxygen, but with the participation of lower organisms, for the development of which there is a very favorable environment, rich in protein substances. Preparation of leather consists of the following operations: 1) preparatory operations (see Leatherworking), used in the following order: soaking, washing, liming, beating hair and the top layer of skin (Narbe, grain), new liming, fermenting or boiling, squeezing and 2) soaking with fat and finishing the leather. Regarding the preparatory operations, only the features of these operations during the preparation of leather will be reported here (for details, see Leather production). Skins subjected to suede are first of all soaked in the usual way, washed, stretched and immersed in an ash pan (containing more lime than for tanned leathers). The skins remain in the ash pan until the wool can be easily separated in tufts. Then the skins are taken out, the wool is knocked off with a sharp knife, while simultaneously removing the top layer of skin (Narbe), or the last operation after beating the wool is performed separately, to obtain the latter in a purer form. Removing the top layer from the skin prescribed for skin is a particularly characteristic difference between the latter and other types of treated skin; it is produced because this layer consists of denser tissue, is more difficult and less uniformly saturated with fat, remaining harder and less elastic. Only very thin skins do not remove this layer when sueding. After the described operation, the skins are again returned to the ash pit for 1-2 days, then the flesh is knocked off, smoothed and leveled; Thick skins are once again immersed in an ash pit for 1-2 days, and ordinary skins are directly washed in running or warm water. Gilding of the skins after beating the wool is done to loosen them as best as possible. Further, to remove the lime remaining in the skin after washing it with water, the skins are fermented or boiled in an acidified liquid prepared from bran with water and containing lactic and acetic acids. Typically, fermentation is carried out first in vats, in which the skins are left in fermenting liquid for several hours, and at the end, the leather is simultaneously mechanically processed, preferably in a fulling machine, to accelerate the absorption of fermenting liquid by the skin. During mechanical processing, fermenting liquid is gradually added. Fermentation and mechanical processing require 12-15 hours. A sign of sufficient treatment is the milky white color of the skin and its uniform transmission of light; dark spots in the skin indicate remaining lime (believed to be in the form of lime soaps); in this case, felting is carried out again with fermenting liquid, otherwise the impregnation with fat will be uneven. To remove excess fermenting liquid, the skins are squeezed out or, better yet, pressed and then soaked in fat. For impregnation, various varieties of blubber are used, in some factories exclusively whale blubber (Walifischthran, huile de baleine, whale oil), although in general it is important to use only transparent clarified blubber. The skins are laid out on the table, the front side is moistened with blubber, rubbed in by hand, each skin is rolled into a ball, and felted in a machine (up to 150 small skins are processed in the machine at a time). Felting lasts 2-3 hours, depending on the thickness of the skins, after which the skins are hung in the air. During airing (1/4 - 1/2 hour), part of the water contained in the skin evaporates and further absorption of fat occurs. After airing, the leather is again rubbed with fat, again felted and hung in the air and this entire series of operations is repeated (6-12 times) until the leather loses its usual smell and a mustard smell appears. Immediately after felting, most of the fat can be extracted from the skin unchanged by various methods. The amount of fat consumed for each leather of average size and thickness, with each felting, is about 1/2 kilo, and in total up to 6 kg. Fully saturated with fat, the skins are first hung in a warm room until it warms up, and then they are piled on the floor and covered with linen. The temperature begins to rise quickly. The progress of the process is judged by testing the pile with your hand: if only pleasant warmth is felt, then the progress of the process is considered correct; according to Wiener, the most favorable temperature for this process is 30-36°, check. 4 0°. To ensure uniform heating, the skins are rearranged: those in the middle of the pile are placed in the base and cover, and the rest in the middle. When self-heating of the skins stops, the process should be considered complete; then they sort out the heaps. Practitioners are usually guided by other signs and consider the process to be completed when the skin turns yellow. A modification of the described process is that the felting of leather with ordinary blubber is carried out only once, but for a longer time (German method), then it is ventilated and placed in heaps. After soaking with fat and after lying in heaps, the skin is cleaned from the front side with a special round knife (Schlichtmond) and the unchanged fat is removed from the skin. To do this, use two methods. In French method - the skins are left to lie in water and then pressed in a hydraulic press, and most of the unchanged fat (moëllon) is released. After that, the skins are washed in a solution of carbon dioxide or caustic alkalis, then washed with water and dried. In German In this method, the skin is directly treated with warm alkaline solutions, then washed with water and dried. The resulting alkaline emulsion is saturated with sulfuric acid and the separated fat, called degras, is used to fatten tanned leather (the aforementioned moëllon is even better for this). Finishing suede consists of stretching and ironing it. Suede is yellow in color; To obtain white suede, yellow suede is bleached. Whitening of skin is done either by exposing wet or moistened skin with a weak alkaline solution to the sun, or by treating the surface of the skin with a weak solution of first manganese-potassium salt, and then, to remove manganese peroxide deposited on the skin, with a solution of sulfurous acid. Z. are also painted in different colors. Z.'s use is now more limited than before. In addition to gloves, it is used as a material for clothing, for many products and technical purposes.

Of the modifications of the suede method, two that were proposed in modern times deserve mention: the Klemm and Preller methods. The essence of Klemm's method is that after ash, beating and fermentation, the skins are treated with alum and salt, as in white tanning, then washed with water, so that only a small amount of aluminum salt remains in the skin; then the skin is impregnated with a special composition, which is a mixture of barley flour, brains and blubber, diluted with warm water. Preller's method is a modification of the previous one, and the mixture used to soak the skin consists of oatmeal, brains, milk, cow butter, horse fat and salt or nitrate. The leather obtained using these methods (Crown-leather) is particularly strong. The so-called “transparent leather” (Transparentleder), which is prepared by soaking skins in glycerin, belongs to the same genus as Z. This leather is used for belts.

V. Rudnev. Δ .

The difference between suede and other materials

Suede products are valued for their sophisticated appearance, as well as durability, strength and hypoallergenicity. However, the range of textile products includes many analogues of suede, which differ from natural fabric in both positive and negative properties.

How to fake suede

Sometimes unscrupulous sellers, wanting to earn more, pass off artificial material as natural. To avoid falling for the tricks of such sellers, when purchasing products, pay attention to the parameters indicated in the table.

| Properties | Natural suede | Fake |

| Appearance | It will never be perfectly smooth or evenly colored. | The paint lies evenly and there are no flaws on the surface. |

| Pile | If you run your hand over the surface, the pile will change texture and color. Its surface will be very soft and velvety. | The pile always remains the same and feels a little rough. |

| Wrong side | Soft and pleasant, reminiscent of velvet paper to the touch. | Has a fabric base. |

| Exposure to moisture | Absorbs water. | Repels moisture. |

| Tactile sensations | It gets warmer after a short touch with your hand. | Remains cold after contact with skin. |

| Tag | Quality products always have a sample of the material. | There is no sample tag. |

| Smell | Smells like genuine leather. | It either emits a synthetic smell or no smell at all. |

| edge | The section shows a homogeneous structure. The edge is processed using a special method without bending. | If you carefully examine the edge, you will notice a thin layer of fabric. The cut can be folded. |

| Creases | Quickly returns to its original form if the material is bent. | There may be creases on the surface. |

The difference between natural suede and artificial or eco-suede

You can find 2 types of eco-suede on sale:

- a less strong and durable material created by gluing fibers to a dense base;

- a more wear-resistant fabric made using looped synthetic threads.

Unlike their natural counterpart, artificial fabrics have the following advantages:

- a humane manufacturing method, since no animals suffer during the production of the fabric;

- more budget option;

- the paint applies to the material correctly and evenly;

- Thanks to synthetic impregnations, products are more durable and last longer.

Despite these advantages, eco-suede, like natural fabric, requires careful care and does not tolerate moisture. In addition, the material does not “breathe” well, retains heat or cold, and can cause skin reactions. In addition, cheap versions of artificial suede have a specific synthetic smell, and their surface wears off quickly.

How is it different from genuine leather?

As you know, natural suede and leather are similar materials, as they are made from animal skins. Suede is very different from leather in appearance and production method. Leather products, like suede ones, require careful care, are flexible and durable, do not cause allergies and are highly breathable. However, smooth leather is able to repel moisture, which is not inherent in natural suede.

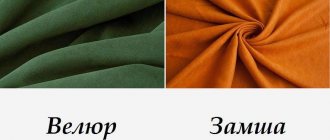

How to distinguish from velor, flock and nubuck

Unlike natural suede, velor, flock and nubuck are rougher and tougher materials.

Velor can deteriorate even with a single exposure to moisture or detergent. The pile is long and easily changes direction. Fingerprints are always visible on the surface of the velor. There are always creases in the material, and the pile actively attracts dust, wool and threads.

Nubuck is a less durable material. In appearance it is smoother than suede. Nubuck wears out quickly, loses its shape and color. After a short period of use, creases and cracks appear on the surface.

Flock is considered a durable material, and its properties resemble velvet. Unlike suede, its fabrics have a shorter pile, obtained by spraying small particles of wool or cotton. The material absolutely cannot withstand exposure to moisture, becomes highly electrified and wrinkles.

How is suede different from split leather?

Despite the fact that split leather, like suede, is of a natural nature and is made from animal skins, it also has characteristic differences. If suede is made from the top layer of hide, then split leather is made from melon or hide layer. Split wood has a perfectly smooth, velvety surface, as it is processed with a knife and special compounds. Unlike suede, the material does not restore its shape well, lasts much less time and does not withstand exposure to moisture at all.

Natural suede: characteristics

The production of suede involves tanning and impregnating the skins of deer or sheep with special fats. The process produces thin leather with short fibers on the front part. Suede has a high heat capacity, breathes well and is very thin. The main advantages of using this material are described below.

Natural suede

Advantages of natural material:

- Exceptional strength, which is more surprising considering the fairly thin layer.

- They allow air to pass through perfectly without interfering with cellular respiration.

- They retain their original appearance for a long time.

- Exceptional softness and porosity of the material.

Video: what suede looks like and how to correctly determine the naturalness of the leather

In the video this is what natural suede looks like

The disadvantages are the high cost. Despite the development of modern industry, tanning hides requires no less expensive methods than centuries ago. In addition, the quality of raw materials is also much inferior, so the problem of obtaining good suede is relevant every year. The second serious obstacle before purchasing (especially shoes and outerwear) is considered to be low moisture resistance.

The porous surface gets wet quickly, so use may be a little limited. At the same time, the use of special impregnations will help to at least partially solve this problem.

Which shoes are better: suede or leather?

Before you decide which shoes to buy: suede or leather, decide on the conditions under which they will be used. For example:

- if you need the warmest boots possible, give preference to suede;

- if you plan to wear boots in wet weather, choose leather products;

- Patent leather can crack in the cold.

In any case, before purchasing, carefully inspect the shoes for quality and naturalness, try them on and determine which shoes you feel most comfortable in. If you use dirt-repellent products and carefully care for the products, you can buy both suede and leather shoes.

Suede is an elegant and aesthetic material. The fabric is quite durable and elastic, breathable and at the same time warm, very pleasant to the body and does not cause skin reactions. The disadvantages usually include the ability to absorb moisture and instability to mechanical stress, which can be avoided with careful use and delicate care.

Advantages and disadvantages of the material

Natural and artificial suede are very similar in appearance. But these fabrics differ in their performance properties.

Natural material is stronger and lasts longer. You can determine what fabric an item is made from using the following features:

- natural smells like leather, artificial has a slight chemical smell;

- natural suede has a clearly visible porous structure;

- The thickness of the fabric of natural suede is not the same everywhere;

- the pile of artificial fabric is lighter at the base, darker at the top;

- natural fabric is always expensive.

The advantages of natural suede include:

- good breathability;

- ability to retain heat;

- soft surface;

- elegant appearance;

- strength.

One of the disadvantages is the rather high cost. Since the material is electrified, it collects dust and small debris, the clothes have to be constantly cleaned. The action of water causes suede to become deformed.

Review of the pros and cons of fabric: