The health and functionality of the musculoskeletal system, namely the spine, largely depends on the quality of the mattress. Many people note that when they wake up in the morning, they feel broken, tired, and their muscles ache. The reason may be an unsuitable mattress - too soft, worn out, with dents. Struttofiber is a filler for new generation mattresses, which over several years has managed to establish itself as an elastic, wear-resistant material.

Features of struttofiber production technology

The name “struttofiber” comes from combining two words:

- "strutto" from Italian. It indicates the vertical arrangement of fibers in the filler;

- “fiber” from English, that is, “fiber”.

The name does not refer to what the padding is made of, but to the way the fibers are laid inside it.

What is it made of?

The base is polyester. In addition to artificial fibers, threads of natural origin can be added to the raw material: camel wool, goat wool, cotton wool, flax, coir, sisal, horsehair, seaweed.

Any type of additional natural fiber gives rise to struttofiber with different properties:

- increased warmth (wool);

- ability to regulate temperature (linen);

- elasticity (horsehair);

- rigidity (coir, sisal).

Material properties

The fibers from which the future filler will be created are placed vertically or at a slight angle. For this purpose, the aerodynamic method of laying fibers is used. They are then held together using a combination of hot air and high-fusibility polyester.

The thermal bonding method makes it possible not to use adhesives containing toxic elements in production.

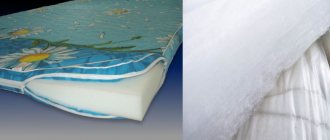

The result of the work is an elastic mat with springing properties. A large number of fibers laid using a special technology provoked the appearance of the name “non-woven autonomous springs”.

The main layer, where the threads are located vertically, is fixed by securing additional layers of reinforcement made of polyester on both sides.

This is interesting: Holofan insulation: description, properties, environmentally friendly and safe

It appeared on the market recently and immediately became a leader among mattress fillers. And all because it has outstanding performance properties. We talk about struttofiber, its production and features.

How is struttofiber produced?

Struttofiber is a synthetic non-woven material made from polyester with vertical fibers. Struttofiber is relatively young. It was developed by Russian technologists from Podolsk. And for the first time they presented the material to the public at an international exhibition in Moscow in 2012, where it was to the taste of not only domestic but also foreign consumers.

By the way, struttofiber owes its name to the Italian and English languages. The word “strutto” in Italian means “vertical”, “fiber” in English means “fiber”.

Struttofiber is produced using a unique technology. First, the fiber is subjected to thermal treatment. The resulting material is then processed in a wind tunnel using a combination of hot air and high-fusibility polyester. Thanks to this procedure, the fibers are arranged vertically and firmly bonded to each other.

The result is a canvas resembling an elastic mat. The main layer of struttofiber is a huge number of fibers laid using a special technology, which technologists call “non-woven autonomous springs” due to their external and functional similarity. The base layer is reliably fixed thermally and supplemented with layers of polyester reinforcement.

At the same time, the fibers remain independent, and the struttofiber acquires special characteristics. It is important to note that this method of thermal bonding makes it possible not to use adhesives with toxic elements in production. The material turns out to be absolutely safe.

Properties of mattresses made from struttofiber

A special technology for manufacturing the filler provides mattresses made from it with unique properties.

- Mattresses made from struttofiber are distinguished by elasticity, elasticity, springiness and durability. Such products are resistant to deformation, they are convenient to transport and store when folded.

- The special arrangement of struttofiber fibers allows air to circulate freely inside the mattress, making it “airy” and light. Such mattresses have good heat and air exchange.

- Mattresses made from struttofiber (without additional additives) are hypoallergenic and suitable for children.

- The struttofiber filler does not absorb moisture, it can be used outdoors, in the countryside, in rooms with high air humidity, in a coastal climate. Also, mattresses made from this filler can be washed, disinfected, treated with hot steam, and dry-cleaned. Another obvious advantage is that they dry quickly.

- Strutto fibers do not harbor mites, fungus and mold.

- A mattress with struttofiber does not smell of anything, does not absorb extraneous odors from the room - sleeping on it will be especially comfortable for people who are sensitive to various aromas, as well as for those who suffer from asthma.

- A number of models of spring and springless mattresses containing strutto are sold “rolled”. You can even take away a double mattress in your own car.

Additional additives in the composition of struttofiber

Often, manufacturers, in order to improve and “expand” the positive properties of struttofiber mattresses, enrich its composition with additional components. These are mainly components of natural origin, so be careful when choosing a struttofiber mattress with “ingredients”: they may be allergens.

- To make it warmer to sleep on the mattress, natural wool is added to the struttofiber: goat, camel or sheep. Often this material is used in double-sided mattress models, where one side is summer, with a cooling effect, and the other is winter, that is, warming.

- To give the mattress thermoregulatory properties, thanks to which the sleeping place can be adjusted to the temperature of the sleeper, struttofiber with the addition of natural flax is used as the top comfortable layer.

- To make the mattress more rigid, coconut coir or sisal from agave leaves are added to the struttofiber. But to achieve greater elasticity of the sleeping place, manufacturers use struttofiber with the addition of horsehair.

- There are mattress models that have antibacterial, antiseptic and bactericidal effects. To make them, they use struttofiber with bamboo fiber, eucalyptus, aloe vera or seaweed.

Characteristics of mattresses with struttofiber

Struttofiber filler comes in different densities: from 75 g/sq. m. up to – 2500 g/sq. m. The higher the density, the greater the rigidity of the mattress. Also, the rigidity of the mattress depends on the thickness of the strutto layer.

A small layer of dense struttofiber (even up to 5 cm high) is suitable for hard sleepers, children under six years of age and people weighing over 90 kg. Also, hard mattresses are usually recommended for those who have problems with posture. Additional rigidity, and, accordingly, support for the spine, will be given to the product by layers of natural coconut coir or artificial coconut fiber, and fillings made of cellular or soy foam.

A sleeping place with a layer of struttofiber from 5 cm has an orthopedic effect and has medium or moderate rigidity.

For those who prefer to sleep on something soft, a mattress made of struttofiber with the addition of natural or artificial latex, as well as memory foam that takes into account anatomical features, is suitable. After 50 years, you need to monitor the condition of your spine with double attention. A mattress that is too hard can harm him. It is better for people of this age to pay attention to soft fillers.

Struttofiber is often used in spring mattresses of different price categories. In models with a spring block, the bonnel strutto will perform not only an insulating function, thanks to which the sleeper does not feel the spring, but also a protective one. Struttofiber will save the top cover from abrasion and extend the life of the mattress.

In more expensive models of mattresses with an independent spring block, struttofiber will enhance the orthopedic effect and provide excellent air exchange between the layers.

Who is suitable for struttofiber mattresses?

Remember at the beginning we wrote that struttofiber was first presented at the international furniture exhibition in Moscow in 2012? So just a year later, in 2013, it received the international safety certificate Oeko-tex® Standart 100 Class 1 (products for children). This means that the material is excellent for the production of children's mattresses from 0 years old; harm from struttofiber even for newborns is completely excluded. The Oeko-tex standard is an international independent certification system for textile products. The tests are aimed at identifying harmful substances, and the results are regulated by European safety standards.

Another interesting fact about struttofiber: according to some manufacturers of struttofiber mattresses, the independent non-woven springs of this material prevent the development of scoliosis, hypertension, and are a preventative against heart disease and radiculitis.

Also, mattresses made from struttofiber are suitable for people who have problems with posture and spine. A sleeping place made of strutto is recommended for all those suffering from osteochondrosis of the cervical and thoracic spine, since the mattress is able to provide maximum relaxation of the muscles that support the spinal column.

Orthopedic doctors recommend mattresses made of struttofiber for the care of bedridden patients: moderately soft and elastic struttofiber filler helps to avoid the development of bedsores.

How to care for a struttofiber mattress?

Manufacturers claim that struttofiber mattresses last up to 10 years on average. But the sleeping place where we spend half our lives requires quality care.

To ensure that the product does not cake, serves for a long time, retains all its original properties and does not deform, it should be turned over every three months.

Directions for using struttofiber

The filler is recommended to be used in two main directions.

- Production of mattresses with an orthopedic effect from a homogeneous filler or with various additives.

- Production of upholstered furniture. Sturttofiber successfully replaces foam rubber on armrests, backs, and the back of sofas and armchairs. The filler is used in the repair of upholstered furniture.

The packaging indicates the area of possible application of the material. Use as directed will extend the life of the product.

What properties to consider when choosing

When trying to choose which filler is best for a mattress, you should focus on individual needs, personal preferences and medical prescriptions. You can choose the best filling for a mattress based on its key properties:

- Naturalness. Natural substances are more environmentally friendly than artificial ones, although they are more expensive. Sleeping on natural material is more natural and pleasant for a person, but in some cases it can cause an allergic reaction.

- Ventilation. Air permeability, and therefore comfort and safety of sleep, depends on what fillers in the mattress. Dense structures will accumulate moisture, causing mold formation and rotting of the structure from the inside, absorb unpleasant odors, and provoke allergies and skin diseases.

- Rigidity. The appropriate hardness is selected according to individual preferences and medical indications. Soft is suitable for people with diseases of the musculoskeletal system, blood vessels, joints, the elderly and those who like to sleep on their side. The average one will be ideal for back problems. Hard ones are necessary in childhood from birth until the final formation of the spine, as well as in the presence of intervertebral hernias and postural disorders. Combined ones allow you to change the hardness by turning the product to one side or another in accordance with your well-being and mood.

Struttofiber: what is it

A little history

Struttofiber is a non-woven material, the result of technological developments of the Podolsk factory “Ves Mir”. It was developed as an environmentally friendly and practical replacement for polyurethane foam as a filler for mattresses. It was first presented in 2012 at the 24th international furniture exhibition in Moscow. In 2013, it received the international safety certificate Oeko-tex® Standart 100 Class 1 (products for children).

How to produce

It is produced using the Italian “strutto” technology, which is where the name comes from. The fibers are laid in a special way - vertically, and bonded under the influence of hot air. The process is called thermal bonding; it eliminates the need for glue, which guarantees the environmental friendliness of the filler. Due to their vertical arrangement, the fibers work like springs in an independent spring block and give Struttofiber an orthopedic effect.

What does it consist of?

The base is polyester fiber. To obtain various properties, wool, cotton, flax, bamboo or coconut coir are added to polyester. For example, wool in the composition allows you to obtain a material with a warming effect, and flax - with a thermoregulating effect. Coir makes the filling more rigid, and cotton makes it softer.

Advantages of struttofiber

- High orthopedic performance due to the vertical arrangement of the fibers.

- Good degree of elasticity . Restores shape much better than polyurethane foam and foam rubber.

- Service life more than 10 years with proper care.

- Created without the use of glue .

- Good air permeability. Does not absorb odors and does not accumulate moisture. Accordingly, the risk of mold and mildew growth is reduced .

- Does not provoke allergies.

- Adding natural components improves the consumer characteristics of the filler.

- Meets global safety standards . Recommended in the production of mattresses for newborns.

Struttofiber - who should “accept the laurels”?

The problem of the ideal price/quality ratio of mattresses was partly solved by a domestic manufacturer - the Podolsk nonwoven materials factory “Ves Mir”. In April 2012, at an international exhibition held at the All-Russian Exhibition Center in Moscow, the factory presented its new invention - Struttofiber mattress filler. Non-woven material has been called a modern substitute for foam rubber.

This is interesting: Felt fabric: properties, description, production and scope of application

Strutto mattress – comfort at an affordable price

Having adequately assessed the features of strutto material, users also favorably note its reasonable cost for such long periods of trouble-free operation. The companies that create the products have an impeccable reputation, which is why mattresses filled with struttofiber receive extremely positive reviews.

Many fans of high-quality orthopedic mattresses have long answered the question: which is better - struttofiber or latex? Their choice fell on strutto fibers as a more durable, safe material. They can be used by adults and children, and manufacturers also recommend the use of mattresses for people with problems of the musculoskeletal system, including those with osteochondrosis. Struttofiber is indispensable for bedridden patients; it prevents the occurrence of problems such as bedsores and does not cause discomfort.

The mattress will help you successfully relax your muscles, support your spine and give you a deep, pleasant sleep, which will be replaced by pleasant sensations in the morning. You will be able to feel cheerful, healthy, and most importantly, completely ready for the new day.

Comparison with analogues

In addition to struttofiber, other fillers are also used for mattresses. One of them is holofiber. Both materials are non-woven. Holofiber is also elastic and breathable, environmentally friendly. The fibers in it are located in different directions. Products with holofiber are more expensive, but also last longer.

Another analogue of filler is latex. Its synthetic origin gives it the same advantages as struttofiber. Latex is soft and elastic, at least twice as durable, but also more expensive.

Polyurethane foam is more resistant to heavy loads than struttofiber, but less durable. Over time, it wrinkles and may crumble. The advantage of polyurethane is that it takes the shape of the body. The elasticity and softness of the filler resembles natural latex.

Another artificial material is cholcon. In terms of characteristics, it is almost identical to struttofiber, but costs more.

Price-quality ratio

The price of a mattress with struttofiber is comparable to the price of bedding with other artificial fillings. Moreover, among all of them, strutto has some of the best characteristics that do not in any way harm the health of the buyer.

For a product with a material created using new technology, the price is more than understandable. Such a mattress instantly takes on the contours of the body, and then quickly recovers. It is very durable.

Price – from 3 to 10 thousand rubles. Luxury mattresses, where the filling contains an admixture of natural fibers, cost up to 20 thousand rubles.

Operation and care

The strutoplast mattress is a material that does not require careful maintenance.

Advice! To increase the service life, it is recommended to use a mattress pad. This will prevent the case from getting dirty.

To avoid squeezing, it must be turned over regularly, so when purchasing, it is better to give preference to double-sided models. In case of severe wetness, it is necessary to remove the mattress cover and cover, and place the mattress itself near the wall and leave it until completely dry. To prevent dust from accumulating in the fillers, it must be vacuumed periodically.

"Talking" name

This trademark was registered by its manufacturer - the Podolsk nonwoven materials factory "Ves Mir". The non-woven filler received excellent performance characteristics and quickly became one of the best products for the production of mattresses.

The name of the filler fully corresponds to its essence. It consists of two parts. What is strutto and fiber:

- “Strutto” denotes Italian technology, which involves the vertical arrangement of product components.

- "fiber" is translated as "fiber".

Thus, sruttofiber is strutto fiber. The filler consists of two parallel planes, between which there is a supporting layer with vertically arranged fibers. They have the ability to optimally redistribute the load, similar to an independent spring design. It is no coincidence that the second name of struttofiber is “non-woven independent springs”.

All about composition and production

Strutoplast in a mattress is a material made of synthetic fibers, consisting of 3 layers:

- reinforcing bottom;

- polyester;

- upper reinforcing.

The layers are connected under the influence of high temperatures.

The first part of the material’s name “struto” means that the fibers are placed vertically and do not intertwine horizontally. This technology is also called independent springs, that is, if you press in one place, it will sag straight down, and the adjacent parts will remain in place.

To increase thermal properties and enhance air exchange, natural fibers are added to struplast:

- sheep wool, durable, absorbs moisture, allowing the filler to “breathe”;

- camel wool, with similar properties to sheep's, but more expensive;

- seaweed, which does not cause allergies, dries quickly, contact with it has a positive effect on the condition of the skin;

- bamboo, elastic, hygroscopic;

- linen, which allows you to maintain body temperature.

The most common mattress filling that is mixed with synthetic fibers is coconut coir. It increases rigidity and is inexpensive.

Advantages and disadvantages of Struttofiber filler

Struttofiber can be considered a budget replacement for soft and medium-hard brands of polyurethane foam. Of course, it will not compete with extra-hard, highly elastic and viscoelastic brands, but it will compete with the standard ones, often used in mattress production.

pros

According to the developers, the material:

- quite dense;

- elastic, quickly restores its shape, similar in properties to polyurethane foam;

- the work of vertically laid fibers can be compared to the work of numerous independent microsprings;

- breathable;

- does not absorb moisture, does not rot, is not flammable;

- unfavorable for the life of microorganisms, hypoallergenic;

- declared service life is up to 10 years.

Minuses

In comparison with high grade polyurethane foams:

- unstable to prolonged increased loads, and therefore not recommended for heavy consumers;

- relatively short-lived (compared to coir and latex);

- mattresses and toppers with Struttofiber filling cannot be folded or rolled up, as this leads to destruction of the structure.

Recommendations for making the right choice

If you plan to purchase, then you need to find out what features and recommendations exist for choosing products made from struttofiber.

For example, it is very important to take into account the manufacturer's specified operating requirements. One of them is the maximum load on the sleeping place. Typically this figure ranges from 90 to 160 kg. The greater the weight, the more expensive the mattress, since it requires additional strengthening.

It is also necessary to focus on the person’s weight when choosing the firmness level of the mattress.

- People weighing up to 60 kg will sleep comfortably on a soft mattress.

- 60-90 kg – a product of medium hardness is suitable.

- Over 90 kg – you need to choose a hard mattress.

Choosing a mattress is not an easy task, because you need to take into account many nuances.

For example, not only the weight of the future owner matters, but also age. This is due to the fact that the condition of the spine is different at different periods of life.

- Children under 2 years old require a firm mattress. This contributes to the correct formation of the spine.

- From 2 to 25 years old, you should choose a product of medium hardness, but this is in the absence of problems with weight or spine.

- From 25 to 50 years, you can choose any mattress you like.

- After 50 years, the spine is already quite worn out and requires increased attention. Hard mattresses will lead to deterioration of the condition of the vertebrae and intervertebral discs, so the choice should be made in favor of a soft filler.

If the mattress has already been purchased and cannot be returned, or the situation has changed and the existing hardness is no longer suitable, you can solve the problem by purchasing a mattress topper of the required hardness.

The next selection criterion is the height of the mattress.

The required height is an individual value, which depends on the bed. Insufficient height will lead to the fact that when sitting on the edge of the mattress, a person will feel the edge of the bed board. It is recommended to choose mattresses with a height of at least 10 cm. It is also necessary to correctly calculate the required length of the mattress. To do this, add 30 cm to a person’s height. Otherwise, sleeping will be cramped.

Various natural components are often added to struttofiber to improve the beneficial characteristics of the mattress. The choice of mattress fillers is quite wide:

- goat hair makes the product warmer,

- seaweed gives the mattress bactericidal and healing properties,

- hard horsehair allows you to give more rigidity and elasticity,

- coconut coir also enhances rigidity. Coir does not absorb moisture, is well ventilated, lasts a long time, but increases the price of the mattress.

Filler composition

struttofayber

struttofayber-2

The basis of the material is polyester, bonded with fusible polyester in a stream of hot air. Synthetic material provides the highest wear resistance and durability to the products. To give special characteristics to synthetic fibers, natural ones are added - wool, flax, horsehair, palm or coconut coir.

Weaving goat hair into the filling makes the mattresses especially warm. Linen, on the other hand, has excellent thermoregulating properties; including one quarter of it in the composition will give the mattress a pleasant coolness.

Horsehair increases elasticity, and coir from tropical trees increases rigidity.

produces several types of struttofiber, among them – Camel Wool, Coconut, Melange, Standard, Regular.

Contraindications

Mattresses made from struttofiber may sometimes not be suitable for people due to their hardness or the natural materials included in the filler.

Allergy

Polyester itself does not cause allergies. But in order to improve the mattress, for example, to make it warmer or more breathable, manufacturers can add other materials to the struttofiber composition, for example, wool or horsehair. They, in turn, can already cause allergies. Therefore, before purchasing, you need to carefully study the description and composition.

Age and low body weight

After 50 years, mattresses should be chosen soft, regardless of body weight.

Hard and medium-hard mattresses are created from struttofiber. You can make the bed soft by additionally placing a soft mattress pad on the mattress or choosing a different type of filling. Before purchasing, it is recommended to lie down on the mattress, and in your usual sleeping position. Only your own back can accurately answer whether the mattress is soft or not.

Middle-aged people weighing up to 60 kg should also choose softer models. With low weight, rigid ones will not be able to replicate the anatomical shape of the body and, accordingly, will lose orthopedic properties.

Osteochondrosis

Those who suffer from osteochondrosis need to carefully choose a mattress from models with moderate hardness. They have less pressure on the vertebrae and intervertebral discs, while repeating the curves of the back.

Remarkable properties of struttofiber

struttofayber-3

struttofayber-4

The material has many excellent qualities, thanks to which it is considered one of the best fillers.

- Not subject to rotting.

- Exceptionally durable.

- It has excellent elasticity and restores shape better than other fillers.

- Does not absorb moisture.

- Does not support combustion.

- Not a breeding ground for dust mites.

- Does not cause allergic reactions.

- Doesn't creak!

- Reasonable price.

Areas of use

The main use of struttofiber is to fill mattresses of medium or low hardness with it. In addition, the material is used in the production or restoration of furniture. It is used mainly for the production of parts that are not subject to heavy loads - these are backrests, armrests and headrests.

Advantages and disadvantages

Struttofiber has many advantages:

- environmental friendliness;

- safety;

- rapid restoration of the original shape;

- breathability;

- quick drying;

- moisture is not retained;

- orthopedic effect;

- comfort;

- long-term operation (from 10 years);

- no susceptibility to rotting;

- odors are not absorbed;

- hypoallergenic - synthetic origin provides protection against mold and dust mites.

Struttofiber has no obvious disadvantages. The only negative is less resistance to high loads than some other fillers. This problem can be solved by choosing the right mattress hardness.

How is filler made?

The filler, unique in its properties, is obtained from polyester fibers. In addition to synthetics, natural cushioning materials are added to struplast:

- goat or camel hair for insulation;

- flax for thermoregulation;

- horsehair to increase elasticity;

- coconut coir or sisal for added strength.

Strutto has a three-layer structure. The outer layers play a fastening role. The main layer with vertical fibers is located between them.

During the manufacturing process of struttofiber, polyester threads are subjected to high-temperature treatment. As a result of thermal exposure, they acquire a spiral shape and become like springs. The fibers are laid vertically using an aerodynamic orientation method and bonded using fusible polyester and hot air. At the same time, the springs remain independent of each other, due to which mattresses and furniture with hollow cores inside have spring properties, quickly return to their original shape and do not form dents.

Features of care

A mattress is an item that is purchased for a long time, so it is so important to ensure the preservation of the beneficial properties of the material and care.

Families with children are familiar with the children's love of using a mattress as a trampoline. Such actions must be stopped, otherwise the mattress will quickly lose its orthopedic properties. The filler will be destroyed. And the harder the filler, the faster it will begin to crumble. In addition, if the mattress has springs, they can tear the fabric covering and injure a person.

To protect the mattress from dust and dirt, purchase a cover. The covers are sold directly, as well as mattress pads and mattress protectors.

- The case is the most convenient option, but it also has a higher price. The mattress is completely covered with a cover, which can be removed and cleaned at any time.

- A mattress protector, as the name suggests, is placed on top of the mattress to protect it from dust and other contaminants. However, the side surfaces of the mattress remain uncovered, which means it will still get dirty.

- The mattress pad performs quite important functions. The bottom of the bed is a frame made of slats located at some distance from each other. Accordingly, dust from under the bed gets into these free spaces. The mattress pad will protect the mattress from dust contamination. It will also take on the negative consequences of friction that occurs between the base of the bed and the mattress, which means the service life of the latter will increase.

To maintain the orthopedic properties of the mattress, you should not lie on one side. You need to turn the mattress regularly. This will allow the filler material to straighten out.

And lastly, at home, care and treatment of the mattress is carried out with a vacuum cleaner, and in order to get rid of foreign odors, it needs to be ventilated in the fresh air more often.

A struttofiber mattress, with the right choice of model, can improve the quality of sleep and have a positive effect on a person’s health.

Care

When caring for the filler, the manufacturer recommends focusing on its composition, in particular, natural inclusions.

There are general recommendations when using mattresses.

In order for the product to serve for a long time and retain all its original properties, you should periodically turn the mattress 180

O

and along the center line.

Struttofiber has high orthopedic characteristics; it evenly supports the human body during rest and is recommended, first of all, for people with a diseased spine. In addition, independent non-woven springs prevent peptic ulcers, the development of scoliosis, hypertension, and are a preventive measure against heart disease and radiculitis.

This unique filler is recommended for everyone who cares about their health and cares about the well-being of those closest to them.

Central office in Podolsk

Address: 142111, Podolsk, Neftebazovsky proezd, building 3 Telephone,

Materials

Springless orthopedic mattresses are made from foam rubber, cotton wool, polyurethane foam, struttofiber, latex, sea grass, horsehair, coconut fiber and many other materials. We exclude the first two fillers, which are cotton wool and foam rubber, from the materials under consideration, since they do not have orthopedic properties. As for other paddings, they allow you to create excellent surfaces for sleeping.

The absence of springs makes these mattresses extremely durable. They can withstand heavy loads, children can play on them, you can even jump on them - the padding will not be damaged. The exception is mattresses made from coconut coir - its slabs can burst and crumble, especially if the manufacturer used needle-punched fiber.

Single-layer and multi-layer

Springless orthopedic mattresses can be single-layer or multi-layer. Single-layer models are made from one material, for example, polyurethane foam. As for multi-layer models, there are several paddings at once, for example, latex, polyurethane foam and coconut coir. Thanks to this, manufacturers can create mattresses with different properties.

Springless mattresses can also be made from composite materials. A typical example is a mattress made of struttofiber, the fibers of which are woven with goat fur. As a result, we get an excellent mattress that retains heat well - suitable for lovers of warm mattresses. But the same structure, only with flax, allows you to create “cold mattresses” that practically do not heat up from human heat.

Memory Effect Materials

Some springless mattresses are made from Memory Foam material (memorix, memoryform, etc.). This padding has a foam structure, and thanks to its properties it precisely adapts to the human body, taking its shape. The padding does not exert pressure in response, since it can bend under the influence of human heat and load - the mattress takes on a shape that corresponds to the pressure contour of the person lying on it. Having risen from the memory foam mattress, we can notice how it begins to restore its shape, spending a few minutes on this.

Springless mattresses with Memory Foam create excellent conditions for comfortable rest. This is truly the latest development, but not everyone likes it, since if the air temperature in the room is too low, the padding material becomes very hard.

Advantages and disadvantages

Now let's look at the general advantages and disadvantages of springless mattresses:

Advantages

Long service life - there is nothing to break, so springless orthopedic mattresses last a very long time; Excellent orthopedic properties - mattresses provide good back support and follow the shape of the body; Wide range of hardness - springless mattresses can be soft and very hard. Flaws

High cost of individual models - some springless mattresses are indeed very expensive, as they are made from expensive materials (natural latex, coconut fiber, memory materials); Insufficient softness - some spring mattresses are much softer than their springless counterparts. How to choose the right orthopedic mattress based on padding materials? You need to pay attention to the rigidity of the material and the comfort of the mattress itself - it would be nice if the store had the opportunity to test individual models.

Comparative characteristics of struplast, latex, polyurethane foam and other fillers

Struttofiber is not the only filling for mattresses. There are a sufficient number of natural and artificial non-woven materials on the market that can compete with it. What is the difference between them and which one is better?

- Polyurethane foam is a foamed polymer, one of the most common materials for padding. Thanks to a special manufacturing method, polyurethane foam has orthopedic properties - it holds the shape of the body, is rigid but elastic. It is used for stuffing orthopedic mattresses. Among the disadvantages of foamed polymer is its low service life. Unlike strutto, it wears out quickly, but is cheap. In addition, there is an opinion that polyurethane foam releases harmful volatile substances into the atmosphere, but the reliability of this theory has not yet been verified. No toxic glue is used in the manufacture of struttofiber, so this material is safe for human health.

- Latex is an emulsion of polymer particles in an aqueous solution. Natural latex is obtained from Hevea juice by foaming, artificial latex is made from synthetic rubber, but its quality is not inferior to natural material. Latex does not cause an allergic reaction and lasts a long time. One of the main advantages is that it is not subject to rotting. Compared to Holcon, latex is quite expensive.

- Hollofiber is another non-woven fibrous material. Mattresses with it are waterproof, but it has a significant disadvantage: over time, holofiber cakes.

- Ecofoam is a relatively new material that has a “memory effect”. It “remembers” the position of the body and takes the necessary shape. However, not everyone is comfortable with this property, so the advantage of ecofoam is also its disadvantage.

- Coconut fiber is a natural filling for mattresses, which is used to create therapeutic orthopedic mattresses for patients with musculoskeletal disorders. This is a hard and durable material that is well ventilated and prevents the proliferation of harmful microorganisms. The disadvantage is the high price.

What advantages does struttofiber have over other fillers? First of all, it has a long service life - from 10 years. Like latex, it does not rot, microorganisms do not multiply in it, and it is hypoallergenic. Mattresses made from strutoplast are breathable, resistant to cold, spring well and restore shape, but they are not recommended for people with very large weights.

Struttofiber and its advantages

Translated, the word means vertical fiber, and indeed, in mattresses, the threads are placed in a vertical position and, in cross-section, have the appearance of fibrous springs.

Among the main advantages that struttofiber has, it is worth noting the following:

- orthopedic properties that ensure optimal anatomical position of the body on the mattress;

- elasticity and resistance to deformation;

- long service life - several decades;

- presence of air circulation;

- hypoallergenic and safe, strutto fiber does not accumulate dust, prevents the development of pathogenic organisms and mites;

- antistatic effect;

- does not support combustion and decay processes;

- quick removal of moisture.

It is very important that such innovative mattresses can be used at any time of the year; they retain heat well and are not able to heat up during hot periods. And they can be purchased in various sizes and modifications - with a medium, moderately hard and hard surface. Many clients do not know which is better: struttofiber or polyurethane foam, but after familiarizing yourself with the advantages of the first, you can independently make the most correct choice.