They talk about what a lobe thread and a weft thread are in the very first labor lessons at school, and for good reason! The split thread determines how the item you sew will look. If you neglect the direction of the grain when cutting, the finished product may warp, and during wearing it will stretch out and finally lose its shape.

Note to Beginners: 18 Sewing Terms You Need to Know

Fortunately, avoiding unpleasant consequences is not so difficult; the main thing is to understand the terminology and several nuances.

What is a shared thread?

So, the grain thread is the warp thread running in the direction of the weaving machine. It is precisely because it runs along the length of the canvas that it is called a lobe.

an edge is a strong edge of the fabric, secured using a special textile method.

The weft thread is a thread perpendicular to the warp, and their intersection constitutes the basic structure of the fabric.

How to learn to sew: tips for beginners

Fabrics with patterns

If there is a drawing, it also needs to be analyzed. The pattern can be directional or non-directional.

If the pattern is non-directional and the fabric does not have pile or shading, you can safely lay out the parts both in one direction and in the other, as well as in a jack to save material.

If the pattern is directional, you need, firstly, to immediately decide where the pattern will be directed, for example, to the shoulder seam or to the bottom of the product, and, secondly, to respect this choice when laying it out.

We also analyze the size of the drawing. If it is small, most likely there is no need to join the parts, but if the pattern is large, you need to think about proper combination of details, for example, if you want the flowers to go strictly along the waistline. In this case, fabric consumption increases due to natural reasons. It’s best if you can take the pattern with you to the store and figure out the layout on the spot before purchasing the fabric.

How to determine the shared thread?

Method 1. The simplest and most obvious method of determining the grain thread works in most cases: since we know that the grain thread is parallel to the selvage, no difficulties will arise if your fabric has a selvage.

But it often happens that the edge has already been cut off, and then you will have to use other, more complex methods.

Method 2: This method requires some experience because, despite its apparent simplicity, you will need a trained eye.

All non-knitted fabrics stretch a little along the weft thread and have little or no elasticity along the grain. Take the fabric with the cut edge and pull it in different directions: where it stretches there will be a weft thread, and where it doesn’t there will be a weft thread. Keep in mind: the fabric will best stretch on the bias, that is, at an angle of 45 degrees to the warp and weft threads, but you will notice some deformation of the fabric.

Why is this method not as simple as it seems? There are times when an inexperienced craftswoman feels that the fabric stretches no matter how you turn it. If in doubt, you should use additional methods.

Method 3. Stretch the fabric with a sharp, but not strong movement - along the lobar you will hear a characteristic ringing cotton. Along the weft, the sound will be weaker and muffled.

Method 4. If you are still not sure, try holding the fabric up to the light: the grain threads are always smoother and more even than the weft threads.

Design for beginners: building a straight skirt

Further methods work only in special cases, since they depend on the composition of the fabric!

Method 5. If you know that the fabric consists of cotton and wool threads, then you can be sure that the lobe threads will be cotton threads, and the weft threads will be wool.

Method 6. If your fabric consists of cotton threads and natural silk threads, silk will serve as weft threads, and cotton threads will serve as weft threads.

A grain thread is a fabric warp thread, as well as a line applied to a pattern or pattern of a piece of clothing and showing the longitudinal direction of the warp thread in the piece. In current practice and in the technical conditions for cutting, it is provided for the direction of the warp threads along the parts with allowed deviations that do not affect the quality and fit of the finished product. If provided by the model, the warp thread can go in a different direction. For example, when cutting out parts along an oblique line, when it is necessary to obtain a certain volumetric effect, the warp thread can be located at a certain angle to the part (details of flared products, finishing elements such as flounces, frills, frills, etc.). On parts patterns, as well as on patterns in fashion magazines, the warp thread and its direction are indicated by an arrow.

Every fabric has a warp and a weft - two sides perpendicular to each other. The lobe threads make up the warp of the fabric, and the transverse threads make up the weft. Determining the grain thread is very important when cutting; on patterns the direction of the grain thread is shown by an arrow; it is according to this arrow that the fabric must be laid out.

How to find out in which direction the lobar threads run on a cut of fabric?

Instructions:

- The grain thread always runs along the edge of the fabric.

- If there is no edge on the cut, you can determine the grain thread by pulling the fabric: the warp threads are stretched tightly when weaving, and the weft threads run more freely, so the grain thread is less stretchable. For the same reason, it is along the grain thread that the fabric shrinks more than through the weft.

- Varying degrees of tension on the fabric threads allows for another test to determine the direction of the grain thread. You need to take the fabric at the edge with both hands at a distance of 7-10 centimeters. Sharply straighten the fabric in this place several times, and you should hear a pop. Due to the strong tension, the warp of the fabric produces a loud clap, while the weft makes a duller sound.

- If you look at the fabric under the light, you can see that some threads are located more evenly, others (perpendicular to the first) - more unevenly. The lobe thread runs in the direction of more uniform threads.

- If the fabric has a fleece, it is usually located along the grain thread.

- If in cloth fabric there are cotton threads in one direction and wool in the other, then the wool threads are always weft.

- Knitted fabric stretches in different directions, but in different ways: along the warp, the knitwear is pulled into a tube, and across the warp - like an accordion.

- If the direction of the grain thread is not followed, the finished product may stretch out greatly, quickly lose its shape, or fit incorrectly on the figure.

Terminology of garment parts

How to learn to make straight stitches on a sewing machine (tips)

Special hand stitches

How to determine the grain thread in a knitted fabric?

The presence of a selvage again removes the issue, but if it is not there, then the stretchability of the fabric will help you little, although it is believed that in knitwear the lobe will stretch the least. You can also use the following tips.

Method 1 . Upon closer inspection, you will see that the knitted fabric consists of looped columns and rows. The direction of the columns corresponds to the direction of the grain thread, the rows correspond to the direction of the weft thread.

Method 2. Some types of knitted fabrics are rolled up along the edge into a tube. Since the material lies flat along the grain, this feature will help you identify it.

How to sew a hole in knitwear: 7 different ways to repair different holes

How fabric is built

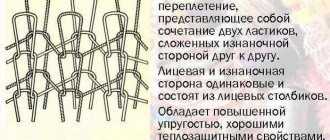

The fabric is woven from two systems of threads, which are called warp, or lobe, and weft. The first ones are located along the edge and parallel to each other. The base is usually homogeneous and very durable. During the weaving process, the supporting threads are stretched and bent, and in order to maintain their strength, the grain threads are reinforced with adhesives - sizing.

The weft thread is perpendicular to the warp and stretches from edge to edge. The wefts are subject to less stress when creating the fabric, so less strong and heterogeneous threads are taken on this role. And one more difference from the main yarn, which remains unchanged throughout the entire fabric: the weft can consist of fibers of different colors.

First, the grain threads are pulled onto the machine. The weft is used already in the process. It is laid down in different ways, which forms the types of matter.

Basic weaving methods:

- plain - homogeneous, grainy when using twisted yarn;

- twill - similar to linen, with a diagonal rib;

- satin and satin - smooth due to the fact that the weft goes mainly under the warp, emerging on the front side through 4 threads or less.

All basic types of weaving have derivative, complicated versions, which determine the variety of materials.

Fabrics with pile

With different pile directions, the same material can look very different! When cutting velvet or corduroy, the parts are laid out so that the pile goes from bottom to top. The reverse direction of the pile is also acceptable, but this issue should be resolved privately, depending on the quality of the material and the length of the pile: hold the fabric to yourself and, looking in the mirror, evaluate how the pile looks in one direction or another.

In all other materials of the suit and coat group that have pile, the parts are laid out in such a way that the pile goes from the shoulder section towards the bottom of the product.

Striped fabrics

The strip can be longitudinal (that is, run along the longitudinal edge) or transverse. In the first case, you need to cut out the parts without deviating in any way from the direction of the warp thread, otherwise you will end up with a defect. In this case, you should also consider whether you will join the strip along the shoulder seam. Cutting according to registration will increase fabric consumption.

If the strip runs across the warp thread, the layout and cutting of the parts must be done taking into account the alignment of the strips in the side and middle seams of the back and front.

Main types of pattern layouts on fabric

Having analyzed the material, we proceed to the actual layout. When deciding how to lay out the fabric when cutting, keep in mind that the choice of layout option is determined based on rationality and economy in each specific case.

Longitudinal fold

In this case, the fabric is folded edge to edge, along the grain thread, with the right sides inward.

Cross fold

The fabric is folded across the grain line, cut to cut, right sides inward.

Partial fold

The fabric is folded only on one side along the lobar, with the right sides inward. This method allows you to make the most efficient use of fabric for any width.

Double fold

In this version, the edges of the fabric are laid along the warp thread to the middle of the fabric, with the right sides inward.

Checked fabrics

Often, combining a small cage turns out to be irrationally difficult, but with some types of cage it is still possible. If the cell on your material is clear and clearly visible, then it needs to be combined.

Despite its apparent simplicity, a checkered pattern can be a very difficult pattern to cut, so you can learn more about the various intricacies of this task in our separate material:

How to cut plaid fabric