Types of holofiber and their application

Holofiber is available in 3 types: granules-balls, canvas and plates.

- Granule ball is the most common and familiar type of filler. The fibers twist to form balls ranging in size from a pea to a ping pong ball. This form of material holds its shape well, does not get knocked down or deformed - it is used to stuff pillows, toys, used as a filler for blankets and gives a three-dimensional shape to decorative items.

This insulation has no negative aspects. Except that it is slightly inferior in heat capacity to a goose feather.

- Non-woven fabric. Holofiber in sheets is available in different thicknesses from 60 to 4000 g/m2. The thinnest canvas is used in landscape design. Canvas with a density of 100 to 300 g/m2 are used as insulation for clothing. Denser fabrics, due to their thickness, density and elasticity, are excellent for making mattresses and upholstered furniture. There are three main types of furniture holofiber: there are also hard fabrics (hard) for creating a frame and flooring, medium (medium) for the top layer and soft (soft) for quilted elements and decorative elements.

Holofiber, due to its structure, is very durable. It does not deteriorate due to physical stress such as squeezing, washing and the like.

- Plates (layers, mats) are produced for construction needs; they are an excellent insulation and sound insulator. Both soft and hard pressed mats are available.

Some types of material are used in the space and aviation industries, as well as in arranging ventilation.

Different types of holofiber are also used in light industry, mechanical engineering, the space industry and aviation.

Cloth

Due to its environmental friendliness and hypoallergenicity, holofiber is suitable for clothing for small children. Parents can wash these items frequently and not expect the clothes to deteriorate quickly.

High thermal insulation will not allow a person wearing a jacket with such insulation to freeze (it retains heat at temperatures below -25⁰C). However, in this regard, holofiber insulation is inferior to Thinsulate. The latter can retain heat down to -60⁰С. However, the low cost of holofiber persuades most people to choose it.

The difference between padding polyester and holofiber

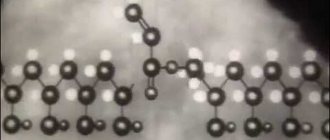

Both materials are synthetic and made from polyester (the most common polyester fiber today). The difference is in the structure of the material and the method of processing the fibers.

The fibers of the padding polyester are laid in parallel layers and connected to each other using a needle-punched method, glue or felting. Due to the use of adhesives in the technology, synthetic winterizer can cause allergies and is not recommended for children's clothing and bedding.

In principle, the material is made from the same fiber, but using different technologies.

Synthetic winterizer is a less durable material, it is short-lived and subject to deformation; when washed, even well-quilted synthetic winterizer gets into clumps. The distance between the synthetic fibers is greater, which means the material is looser and retains heat less well. Clothing with padding polyester insulation is comfortable to wear down to a temperature not lower than -15⁰ C. Due to its disadvantages, it is not intended for industrial use and is not at all suitable for use in construction.

Synthetic winterizer is not the best insulation, as it gets wet and accumulates moisture.

Holofiber production technology is more complex. At the first stage, a layerless canvas is obtained from hollow microspirals; the fibers in the layer are arranged in different directions, thanks to the use of a wind tunnel. At the second stage, the fibers are soldered together using temperature. This connection of fibers is more durable, the final material is elastic, holds its shape well and is absolutely hypoallergenic. Compared to padding polyester, holofiber is lighter, warmer and easier to care for; clothes with such insulation are very comfortable in winter.

Due to the special siliconization method, holofiber does not accumulate moisture, therefore it is successfully used for the production of blankets and pillows.

How can you tell when purchasing which material - holofiber or padding polyester - is used in the product? Sintepon, unlike holofiber, is produced only as canvas. If you try to stretch it, you can hear the crunch of the fibers being shifted; the stretched material does not recover. Holofiber is much softer and lighter than padding polyester. It does not separate into layers and does not make sounds when stretched. Visually, holofiber fibers are always white, somewhat transparent to light and have a gloss, while padding polyester fibers are matte and opaque; low-quality material may have a grayish or pinkish tint.

The material has a low thermal insulation rate.

Flaws

Oddly enough, holofiber does not have many disadvantages. Some ordinary people notice that it can be too hot in clothes or bedding with holofiber insulation. But the essence lies in the physiological characteristics of individual individuals.

When washed in aggressive mode or in hot water, holofiber insulation may become less elastic and more rigid.

Note!

Duvet: TOP-170 photos + video reviews of duvets. Advantages and disadvantages of filler, choice of cover and quiltingBed linen for newborns: requirements for bedding for a newborn. Variety of sizes, materials and patterns of children's underwear (photo + video)

Double bed linen: TOP-170 photo reviews of new designs, choice of size, color and material

Pros and cons of holofiber

Manufacturers and consumers highly value holofiber for a number of useful and unique properties:

- strength and resistance to deformation - thanks to the reliable adhesion of the fibers, the material cannot be torn by hand;

- durability and ease of care - the products can be washed both by hand and in a washing machine.

- hygienic - can be washed often, it will not harbor moths, mites, mold or mildew;

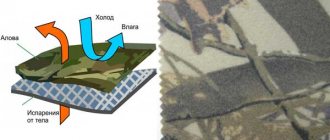

- breathability and moisture resistance - products dry quickly and have a “breathing” effect;

- excellent heat-regulating properties;

- hypoallergenic and environmentally friendly during production and operation;

- lightness and softness;

- fire resistance - when exposed to high temperatures, the filler does not burn, but slowly smolders.

Products containing this filler can be used by both adults and children.

There are few disadvantages to products made from holofiber. Some consumers note that they feel hot in things with this insulation; this applies not only to clothing, but also to bedding. The reason lies in some individual characteristics of the body. You should not wash it in aggressive modes or at high temperatures - it may lose its elasticity and become stiff.

If you wash an item filled with holofiber often and in too hot water, the structure of the fibers may collapse.

Note! Holofiber is recommended for use for children's things, toys and bedding, as it is completely harmless.

Let's consider the advantages of using holofiber in different areas.

- In clothes

Clothes made from holofiber are warm, light and absolutely hypoallergenic, which means they are suitable even for the smallest children. It can be washed frequently and will dry quickly after washing. A jacket or down jacket will keep you warm even in harsh winters at temperatures below -25⁰ C. In clothing, holofiber performs no worse than Thinsulate (a type of synthetic down with high thermal insulation and consumer properties, with this filler it is comfortable down to -60⁰ C) and loses only in ability to retain heat, while it is much cheaper than Thinsulate and is quite suitable for our winters.

Products with filler do not wrinkle, easily return to their original state, and do not lose their properties over the entire service period.

- In pillows and blankets

Hypoallergenic and eco-friendly soft holofiber pillows will give both children and parents a restful sleep, and under light, breathable blankets made of this material it is not cold in winter and not hot in summer.

Such blankets and pillows are very hygienic - they will not harbor bed mites, and washing them is no more difficult than a jacket. For this, the most common washing powder and delicate mode at a washing temperature of 30-40 ⁰C are suitable. You can wring out and dry in the machine and after drying the synthetic filler will not lose its shape and elasticity.

The fibers allow air to pass through themselves well, and products filled with them have a “breathable” effect.

- For furniture production

In furniture production, all types of holofiber are used, usually special brands that have a denser structure and increased elasticity. Decorative pillows and bean bags are stuffed with soft elastic balls. Hard compressed fiber boards are suitable for the production of springless mattresses, including children's ones.

These slabs create an alternative to traditional coconut and foam rubber; they are cheaper, but at the same time more environmentally friendly and durable.

- In construction

In this industry, holofiber has an unlimited scope of application. It has proven itself to be an excellent industrial and household insulation material - it can be used to insulate a building from the foundation and basement to the roof. “Friends” with different building materials - concrete, stone, brick, wood. The material has become a godsend for insulating houses made of timber and frames, including complex architectural forms in the form of domes, monocells, etc.

It is flexible and resilient, reliably filling all the necessary space, regardless of the weather and season. Separately, it should be noted the high soundproofing properties of the sheet material and its non-flammability, which is important for frame and wooden residential buildings.

This insulation is non-hygroscopic and does not harbor fungi and mold.

- In decorative products

Holofiber can be used wherever it is necessary to add volume to the product:

- decorative pillows and ottomans

- toys and souvenirs

- bedding and houses for pets

- different types of handicrafts and hobbies

Parents can give these toys to their children without fear. This filler is also safe for newborns.

Which to choose?

Even after the above description of padding polyester and holofiber, which is better is not easy to understand. The choice depends on the type of products, their operating conditions, and individual user requirements. It is important to take into account the ability of the filler to quickly recover from deformation and not crumple for as long as possible. The product tag on which the responsible manufacturer indicates the compression ratio will help you evaluate this indicator. The digital element of this code must be at least 550.

Holofiber and padding polyester. Comparison table.

| Sintepon | Holofiber | |

| Thermal insulation | — | + |

| Air conductivity | bad | excellent |

| Moisture resistance | — | + |

| Softness | — | + |

| Weight | minimum | minimum |

| Resistance to deformation | — | + |

| Hypoallergenic | hypoallergenic | hypoallergenic |

| Environmental friendliness | — | + |

| Microorganisms | microorganisms do not grow | microorganisms do not grow |

| Terms of Use | moderate-low temperature | low temperature (down to -25°C) |

| Care | there are rules of care | unpretentious |

| Price | low | high |

| Flaws | short service life, prone to deformation, not very warm | high price |

| Advantages | low price, hypoallergenic | Excellent thermal insulation, breathability, wear resistance |

holofiber

padding polyester

Proper care of holofiber

Any product with holofiber filling can be washed both in a washing machine and by hand. Jackets, down jackets, pillows and blankets, if properly washed and dried, will not lose their appearance and consumer properties. The filler will easily withstand intensive washing, steam treatment and mechanical stress, however, when choosing a mode, do not forget that the upper material of the product may require delicate treatment.

Do not overuse active washing - for minor stains, use delicate modes.

Here are the general rules for caring for products with holofiber:

- For minor stains, it is advisable to do without washing. Frequent washing can negatively affect the elasticity of the fiber, and the product will begin to lose its shape and quality.

- If the item is very dirty, it is better to pre-soak it in a soapy solution. Wipe heavily soiled areas with a soft brush or cloth and rinse, and only then put them in the washing machine.

The minimum temperature for using holofiber clothing is up to -30 degrees.

Important! Do not forget to read the product label before washing or cleaning - the upper material can be natural or synthetic and require a more gentle washing regime than the filling.

The logo is the head of everything

Promotional clothing without a logo is meaningless. That is why we put the company logo or other image approved by the customer on the vests. The application method depends on the chosen fabric and the project budget.

- Print is a fairly economical option, but the least durable. Will withstand several dozen washes.

- Embroidery is solid and bright. After a few years, even a well-worn vest will delight the eye with the shine of the silky threads with which we will embroider your logo. Lasts for years.

- Thermal transfer and sublimation - durable and strong like embroidery. The only difference is that the image is applied to a special material, and then transferred to the fabric of the product using a thermal method, rather than embroidered on it.

The best fillings for down jackets

In our climate, a down jacket is a must-have item in the wardrobe. An important characteristic that is important to consider when buying winter clothes is insulation - the service life of the down jacket depends on it, how light and warm it is. When sewing down jackets, both natural and synthetic fillers are used. Which fillers are considered the best?

- The down of waterfowl (goose, swan, eider) is considered the best of natural fillers. It is light, durable and warm, but there are also disadvantages - it requires special delicate care and can be an allergen.

Products with it are quite expensive in price.

- Natural filler with a more affordable price - camel or sheep wool. Jackets and down jackets with such filling are warm but heavy.

Many people can be allergic to wool.

- Thinsulate is the warmest synthetic fill (twice warmer than natural down), it is lightweight, practical and hypoallergenic.

The main disadvantage of Thinsulate is its high price.

- Holofiber represents the golden mean among down jacket fillers, and its low price makes it the leader in our small rating. It is completely devoid of the disadvantages of natural materials and is second only to Thinsulate in terms of thermal insulation properties (it should be noted that in Europe and Central Russia, Thinsulate’s ability to warm in temperatures down to -60 degrees Celsius is clearly excessive and there is no point in overpaying for it).

You should not avoid things made from holofiber just because they are synthetic.

Indeed, just the opposite - such material is more hypoallergenic and does not attract dust. So, a light, warm down jacket for Siberian frosts is Thinsulate, an inexpensive and practical one is Holofiber, and wool and down fillings are suitable for adherents of all things natural.

Holofiber is only one type of a large family of synthetic fillers.

A warm vest is a contribution to business prosperity

What does a company owner get by ordering promotional clothing for staff? Expenses - yes, but not only. In one action, he solves two issues:

- Forms a positive image of the brand among its customers, because looking at a nice vest, they remember the logo and associate it with a neat and high-quality item;

- Forms a positive attitude of staff towards the brand in general and towards management in particular. An employee in warm clothes feels taken care of and becomes more loyal to the manager, which means he works more actively.

Bed dress

The hypoallergenic and highly environmentally friendly material allows it to be stuffed into pillows, blankets, and mattresses. Holofiber pillows will not harbor ticks or moths, and sleeping under a holofiber blanket will be comfortable in both cold and hot weather.

An obvious advantage is that you can

Construction of buildings

Holofiber is widely used in this area. It is used as insulation for buildings. The structure of the material is compatible with concrete, wood, brick, which allows you to create more durable buildings in our time.

Holofiber is flexible and elastic, thanks to its stable shape it fills the entire space presented at any time of the year and at different temperatures. Also, this material is not subject to combustion, which is essential for wooden or frame dwellings.

Compound

Let's figure out what insulation is made of. Holofiber is an artificial material. The filler contains synthetic fibers, mainly polyester. The material is also made from recycled plastic and lavsan.

The production of holofiber is interesting. The harvested raw materials are combed out and hot-molded. The result is hollow fibers with springy properties.

The operating temperature range of the insulation depends on the density. Not least important is the covering material: raincoat fabric, eco-leather, denim, polyester. But when buying outerwear, they focus on average indicators.

| Density | Temperature |

| 100 – 150 g/m2 | +5ᵒC – -10ᵒC |

| 200 – 250 g/m2 | – 10ᵒC – -20ᵒC |

| 300 – 350 g/m2 | – 20ᵒC – -30ᵒC |