Home / Leather and its substitutes

Back

Published: 01/07/2021

Reading time: 3 min

0

300

Split leather is a material that is a layer of genuine leather. Outwardly, it resembles suede or velor. The source of split leather is the skins of cattle and pigs. The material is decorative and practical, and has many other advantages. It is used in various fields and is valued for its low cost. Another name for split leather is split leather.

- 1 Material production

- 2 Types of layers with descriptions

- 3 Pros and cons

- 4 Where is leather used?

- 5 How to distinguish natural split grain

- 6 Product care

- 7 Reviews

- 8 Conclusion

Split leather: what kind of material?

To understand what split leather is, it’s worth getting a little acquainted with the process of tanning hides. Typically, the thickness of untreated skin is from 4 to 8 mm, which does not allow it to be used for sewing products. To adjust the raw material to the desired size, the skin is sawn into several layers. The result is one outer cut of smooth skin and one or more inner layers.

The inner layers are split wood and are divided according to characteristics and qualities. In appearance, the material is porous, loose, with a small pile, reminiscent of suede. It is difficult to call raw materials completely natural, since during the processing process they are coated with special compounds to improve their properties.

Manufacturing technology

The split leather manufacturing process can be divided into several stages:

- Processing and tanning of cattle hides.

- Removing the front layer.

- Chewing is the division of raw leather into layers.

- The layers are impregnated with a special polymer substance to provide additional protection.

- Grinding the surface with a steel plate.

- Emboss outer layer to eliminate scratches and creases.

- Gluing the material to give additional strength, if necessary.

Difference between hide and skin

The first is the raw material for the production of the second. From the moment the ordinary salted linen is received at the factory until the final product, many operations take place (tanning, fleshing, liming). And only then does the division into layers and further refinement take place. Initially, a method was used without the use of chemical reagents. The result was a rawhide product. To impart elasticity, the drying fabric was subjected to repeated deformation. Due to this, the fibers did not stick together and remained flexible and soft. Later, treatment with tannins (ash; ingredients obtained from plants and tree bark) began to be used. The final product takes on the appearance we are familiar with.

Material properties

Split wood comes in different qualities. Shoes, bags, belts and gloves are usually made from the outer and middle layers, which, unlike products made from genuine leather, are much cheaper. It repels water well and is resistant to chemicals, and is also quite durable. By sanding the fabric is given additional properties, making it look like velor and is used as a lining material or raw material for the manufacture of workwear.

The deeper layers of the raw hide are usually used to make raw materials for the production of glue, gelatin or paint products.

Compound

Animal skins are used in the production of split leather. The best leather is considered to be ox hide. It is quite thick, dense, and easy to use. Natural split leather can be obtained from different types of leather.

The material requires mandatory processing, for which embossing and pressing are carried out. Resin-based impregnations are also used. The coating composition includes polyurethanes or acrylic. Additionally, the surface is varnished. You can get an imitation of genuine leather using machines that form a characteristic leather pattern on the surface.

To make natural leather velvety, it is sanded. The material turns out to be soft, fleecy, and looks like velor or suede. The raw material is rough and rough, but retains the advantages of natural leather, which allows it to be used in the manufacture of work clothes.

Types of split fiber fabric

There are several types of split leather, which differ in origin, production method and quality characteristics.

Cowhide or cowhide

The main type of split leather obtained from cattle leather. Typically suitable for making bags, workwear or gloves.

Golyeva

A cut split is a certain part of a layer of cut skin that is sent for the production of belkozin, a food product used to create sausage casings.

Mezdrovy (bakhtormyany)

The layer that is on the untreated skin is on the reverse side. Commonly used to produce adhesives and collagen dissolving products.

With polyurethane coating

Split leather coated with a polyurethane coating is considered to be of lower quality than polished leather, but in appearance it strongly resembles the outer layer of leather. Things made from it practically do not breathe and quickly become unusable due to the fact that the coating loses its strength and bursts.

Felt split

It can be called a technical type, since it is used for insulating rooms, as well as for the production of gaskets and filters in mechanical engineering. Sometimes shoe insoles are made from split felt.

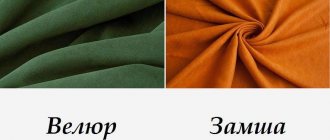

Split velor

From the name it is clear that the appearance of the material resembles velor. Most often, the raw material for split velor is the lower layers of uncut calf skin. The fabric is slightly denser than velor and is usually used for covering furniture.

Lining

Most often made from pig skins and used for the production of shoe linings and duplicating parts.

Pros and cons of the material

Split wood has many advantages:

- easy to process;

- outwardly practically no different from genuine leather or suede;

- costs less than natural analogues;

- allows air to pass through well;

- durable and wear-resistant;

- practically does not absorb moisture.

In the process of manufacturing smooth leather, the layers undergo qualitative changes, due to which the material:

- deformable;

- loses elasticity;

- has high rigidity;

- does not retain heat well.

Despite these disadvantages, split leather is considered more practical and durable in comparison with artificial analogues.

Suede leather.

Fat tanned leather from sheep and goats. Shoes made from it are very soft to the touch and have a special silky sheen. Suede is cheaper than nubuck, but if the processing technology is followed and without “Chinese stretching”, suede shoes are comfortable and retain their beauty and durability for a relatively long time. I quote:

“In terms of properties, it is soft, loose, but durable velvety leather with thick and low pile on the front surface, thin, and well breathable. It is called “washable leather” because it retains its properties after washing in soapy water.”

We must not forget that it is undesirable to expose natural leather to frequent exposure to alkaline media (soap, for example), so you should wash suede in water only if absolutely necessary; there are special products for cleaning products made from it. Suede goes well with other materials of different nature - patent and/or embossed leather, textiles of different textures. Suede shoes are less resistant to wear and tear and are easily damaged by hard and sharp objects, such as stiletto heels or the frames of trolley bags. Such shoes are used for decoration, suede is good for “going out” shoes - constantly wearing suede shoes in the aggressive environment of the Moscow metro, for example, is a risky undertaking, for this it is better to prefer nubuck. It requires more careful care compared to smooth leather and European nubuck; suede is mainly preferred by women. The Bonty online store (Bonty LLC) offers Portuguese suede shoes, which are distinguished by their excellent appearance and resistance to wear and stains.

Where is split wood used?

The material is mainly used for sewing shoes, bags, belts and workwear. If you want to buy a similar product, it is worth studying what features they have.

For shoes

Split leather is used quite often in shoe production. Considering the characteristics of the material, we can say that such products:

- are considered to be of higher quality than things made from artificial raw materials;

- are cheaper than products made from genuine leather;

- look impressive thanks to the velvety surface;

- allow the skin to breathe;

- comfortable to wear;

- tolerate exposure to chemical reagents well.

However, such shoes are considered less durable and do not warm well. Before purchasing split leather shoes or boots, consider the conditions in which you will wear them. For example, demi-season boots for autumn or spring will be less durable, since the material does not withstand moisture and low temperatures. Dry weather shoes, in turn, will last longer.

For bags

Split leather bags are a combination of quality, aesthetics and affordable price. It is quite often used in the production of bags, since its negative characteristics practically do not affect the quality of the products. Products can be found both on sale from global brands and in mass market stores.

Reviews

Irina: Several years ago I had boots made of split leather, but then I didn’t know what they were. Immediately on the advice of the seller, I treated them with water-repellent impregnation and cleaned them with a suede brush. Worn only in dry weather. The boots lasted 2 years, were still in good condition, but went out of fashion, so I donated them to charity.

Olga: I discovered split stitching about 5 years ago, when I started sewing various accessories. At first I made it for myself, now I also make it for sale. Split leather makes good bags and wallets, and there is a wide choice of colors. The material resembles suede or velor, but is noticeably cheaper.

Elena: Last year I bought Carlo Pazolini split leather boots. Before that I wore ankle boots made of the same material, but from a different brand. Winter boots, lining made of euro-fur. Care is the same as for suede products. Along with the boots, I bought a water-repellent spray and a brush.

What is the difference between suede and split leather?

If we compare split leather and suede, we can say that both of these materials are natural and are made from animal skins. The main difference is that suede is made from whole leather, while split leather is made from the middle layer of the hide. As a rule, it is thinner than natural suede, less durable and has practically no stretch.

How to distinguish shoes made of natural suede from shoes made of split leather?

Unscrupulous sellers often pass off split leather as natural suede. As a result, the shoes do not meet the declared characteristics and quickly become unusable. To avoid getting a low-quality product, carefully examine the product before purchasing:

- when compressed, the suede quickly restores its shape, and the split leather retains its wrinkles;

- if the fleecy surface is perfectly flat, it means that you have a split wood cut with a knife;

- if the reverse side is not completely smooth and has veins, then you have suede.

Flaws

Split leather is obtained from dermis, which is more porous than natural leather. Subsequent processing reduces its tensile strength. It is inferior to the epidermis in elasticity.

To make it waterproof, the material can be additionally pressed, polished, or embossed. To improve decorative properties, waterproof polymer coatings are applied to the surface. Resins, varnishes and films close the pores and make it airtight.

Shoes and boots with synthetic coating are comparable in wearability to shoes made of leatherette. But bags, suitcases, and belts made from it look good. They are labeled as leather because they are made from raw materials of animal origin.

How to distinguish split leather

Quite often, the outer surface of split leather is coated with additional impregnation, making it look like natural leather. Sometimes it is also passed off as nubuck or yufti.

From genuine and composite leather

The main difference between split leather and genuine leather is the perfectly smooth and even underside. Also look carefully at the cut of the material - if you notice lamination, it means that you have glued layers of artificial fabric in front of you. If the outer coating peels off during compression, they want to sell you an item of dubious quality.

Composite leather is made from waste from the tanning industry. Small pieces are glued together and coated with special impregnations. The result is a material very similar to natural leather, which is significantly inferior in quality characteristics. You can easily determine that this is a product made of composite leather, since it is quite rough, has a symmetrical pattern over the entire surface and is very wrinkled.

From nubuck and yuft leather

In fact, nubuck is a special type of suede, only the material is denser and is produced by chrome tanning rather than fat tanning. Unlike split leather, nubuck quickly absorbs moisture, so if you slightly dampen the surface, you will notice that this area has noticeably darkened. In addition, if you place your palm on the surface, the nubuck will quickly heat up, but the average cut of natural leather coated with artificial impregnation will not.

Yuft is a natural, very dense, moisture-resistant and heat-resistant leather. Unlike split leather, yuft is softer and at the same time strong, repels water well and easily restores its shape when deformed.

Features of naplak

In the name naplak, shoemakers combined two types of leather - nappa and patent leather. Nappa is made from sheepskin and cattle hides. After chrome tanning, it becomes plastic, soft, and delicate. To achieve a glossy shine, a varnish coating is applied to the nappa.

Naplak models differ both visually and to the touch from the usual varnished pairs. They are softer, thinner and do not crack after 2-3 years of wear. Also, even “difficult” feet quickly adapt to the padding, since the material stretches easily and fits the foot like a second skin.

Naplak also has some disadvantages - it becomes covered with a web of cracks at temperatures below -15° C, does not tolerate impregnation and requires regular care with patent leather shoe products, for example, from the Lack Polish line from Collonil.

True, hardly anyone is going to put on shoes made of naplak in twenty-degree frost or go out in them in rainy weather. This is very expensive leather, from which elegant premium models are sewn.

Caring for split leather shoes and bags

To extend the life of shoes and bags made of split leather, pay utmost attention to the care of the products:

- after each wear of a pair of shoes, vacuum the products, removing all dirt and dust from the pile, and then wipe the surface with a damp sponge and comb with a rubber roller;

- if the surface of the shoes is wet, comb the fibers with a rubber brush, moving in different directions;

- Regularly clean your products from dust using a short-bristled brush;

- to remove abrasions from the surface, rub these places with an eraser or a velor brush;

- Buy a special spray for cleaning natural leather at a specialized store and use it to remove stubborn dirt from the surface.

Also try not to wear products in rain and mud, otherwise they will quickly lose their attractive appearance.

Split leather is a budget type of genuine leather, which is made from the middle layers of untreated cattle hides and treated with special synthetic impregnations. In terms of its properties, the material is inferior to natural leather and suede, but is cheaper and lasts a long time with proper handling and care.

Application

Split velor is particularly dense, so it is rarely used in the manufacture of clothing. However, this material is very popular among designers and fashion designers who make shoes and various accessories. The spectacular appearance allows you to create presentable products in a classic, urban and strict business style.

Split velor is used in the manufacture of:

- shoes;

- bags, wallets, purses, backpacks;

- gloves, belts.

In addition, this type of textile can be used to sew protective clothing for workers in particularly harmful and dangerous industries. For example, many protective gloves are made from this fabric.

- Equipment

- Instructions

Which sewing machine to choose: the best models from budget to computerized

Review of models for industrial and domestic use

The best models for home and production according to customer reviews

Let's take a closer look at the nuances of returning