Kamila_Feodosya

5317 0 3

Kamila_Feodosya September 6, 2016Specialization: professional approach to architecture, design and construction of private houses and cottages, new products on the market of building materials and finishing. Hobbies: growing fruit trees and roses. Breeding rabbits for meat and decorative breeds.

The main advantage is ease of installation, but work must be performed in a respirator

Know-how in the modern building materials market is polyester insulation. Opinions regarding the benefits and advantages, as well as the safety of this insulation for a house or apartment, are radically divided.

Of course, production technologies are being improved literally every day, but is the high cost of this new product justified, and is it safe to insulate a living space with it? I tried to analyze the opinions of professional builders, chemists and technologists, as well as advertising materials from manufacturers.

Naturally, we make allowance for the fact that the manufacturer positions the product only from a positive point of view and exaggerates the advantages, carefully hiding the shortcomings.

Shelter insulation

The content of the article:

- Description and production

- Main varieties

- Specifications

- Advantages

- Flaws

- Criterias of choice

- Installation instructions

Shelter insulation is an environmentally friendly domestic heat insulator of a new generation. It is based on polyester fibers, which are glued together without the use of chemical compounds. The material is universal, has several varieties that can be used to insulate vertical, horizontal, inclined surfaces, as well as inter-crown gaps.

Features of modern polyester

Until recently, it was believed that clothing with synthetic insulation was in many ways inferior to products made from natural materials. The consumer's skepticism was well founded. After all, the polyester produced in the past easily wrinkled and caked, causing the product to lose its shape. In addition, the insulation quickly lost its thermal insulation qualities, and after the first wash the item became completely unusable.

The low quality of the material and the inability of the insulation to meet its intended purpose was explained by the structure of the material.

- In the past, polyester fiber was produced in the form of straight threads and placed in the same plane.

- Now polyester consists of fibers twisted into spirals, balls and tubes, inside of which there are air pockets.

Modern polyester is a light and warm material that perfectly copes with the role of insulation for demi-season and winter clothing.

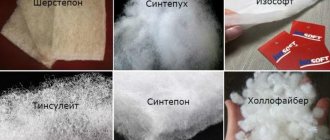

It is impossible to unequivocally answer the question of what temperature a synthetic filler is designed for. After all, the name “100% polyester” can hide Thinsulate, Holofiber, Sintepon, Isosoft and other materials based on polyester fiber. All of them have a certain density and structure, and therefore thermal conductivity.

Synthetic or natural materials

There can be no question which is better - polyester or synthetic winterizer. It is the same. But padding polyester is considered the cheapest type of polyester and retains heat worse than other material options. This means that you should choose it only when there is no opportunity to buy something better. For example, during warm winters, for demi-season wear or for working outside.

What is better to choose, polyester or down:

- Natural down warms better than many types of polyester. But there are synthetic options with the same characteristics or better. For the northern winter, you should choose Thinsulate. Down absorbs any moisture and takes a long time to dry. Due to its naturalness, it is a breeding ground for microbes and insects. Synthetic material is easier to care for. A down jacket requires special care. To avoid freezing in it after washing, you will have to beat it with your hands.

Polyester fillers vary in cost. It's easier to find something that fits your budget. Down products cost about the same and are not cheap.

Types of PE fiber insulation

Products under the ShelterEcoStroy brand of the Ves Mir factory are made from PE threads by heating with air. Construction insulation is not afraid of moisture, heat and frost, and retains its elasticity, shape and low thermal conductivity in any conditions. The material is hygienic and durable; the addition of fire retardants reduces the risk of fire.

It is easy to install and does not create discomfort for installers when cutting and installing. The insulation is effective on any part of the building: roof, walls, floor. Good vapor permeability allows use for wooden houses. Installation of the material is carried out on the lathing; it is similar to laying mineral wool, but does not require waterproofing.

Polytex is a new material on the insulation market. The products are produced by recycling plastic containers. In appearance and properties they are similar to holofiber. Polytex has become popular in Europe due to its properties: environmental friendliness, low hygroscopicity and heat transfer, resistance to biological organisms. The service life of the insulation is up to 50 years, during which time it does not reduce its characteristics.

To achieve fire safety, fire retardant additives are included in the composition.

Politex mats have a low density and minimal weight; they do not load the structure, but are superior to mineral wool in terms of heat retention capabilities. The material is vapor permeable and does not absorb water; when wet, the moisture quickly disappears.

Sintepon is an insulation made of organic fibers with a thermal conductivity coefficient of 0.031 W/m*K. In many respects it is close to basalt wool, but is an environmentally friendly and hypoallergenic product. Installation of thermal insulation can be carried out without special protection. Synthetic winterizer does not change its characteristics when wet, but due to its high breathability it requires the installation of a membrane.

AltEcoBud is a non-woven fabric made of polyester fibers used for thermal insulation of buildings, clothing and other products. The insulation contains no formaldehyde compounds and is environmentally friendly. The material reliably protects from frost and heat, is characterized by low water absorption and dimensional stability.

Among the advantages of AltEcobud: tensile and compressive strength, reusability, long service life, resistance to mold, fungi and insects. The insulation is recommended for insulating floors, walls and ceilings made of any material: wood, brick, concrete. It is used as filler in frame structures.

Description

Polymers, as a product of the chemical industry, are widely used to produce household items and even textiles.

Not everyone knows that polyester fiber is a high-molecular compound based on polyethylene terephthalate with a set of impurities, which is a derivative of petroleum products. To obtain threads for textiles, the prepared mass is extruded at different temperatures, which determines their thickness and characteristics.

Polyester is rarely found in its pure form. It serves as an additive to the composition of various fabrics, which improves their performance. The textile industry has mastered the production of mixed fabrics with silk, cotton, wool and other threads.

Fabrics with polyester fibers have many advantages and low prices. They are tear-resistant, abrasion-resistant, and quickly restore their shape after being crushed due to their rigidity. They are not subject to wear and fading, and do not allow water to pass through. Additional impregnation increases resistance to high temperatures, chemicals and fire. The texture of the fabric is smooth, with a synthetic shine.

Polyester insulation: pros and cons

Until recently, many people doubted whether synthetic jackets were warm or not. We can agree with the skeptics, because natural fur and other materials of natural origin were denser and more reliable than polyester, which was used as insulation.

The raw materials that were produced earlier easily wrinkled and lost their shape. In addition, it lost its thermal insulation properties, and when washed it became completely unsuitable for wear.

Experts compared what the material was like in the past and what it has become now:

- Previously, polyester fibers looked like straight threads running in one direction. This may explain poor thermal insulation and other shortcomings.

- The new polyester is made from fiber that is twisted into spirals, made in the form of balls, in the shape of cylinders. They have air pockets inside. The layer retains heat well and is very lightweight.

At first glance, it is difficult to say what temperature conditions a synthetic item is designed for. If the tag says “100% polyester,” this may mean that the insulation is made from synthetic fluff, isosoft, or other raw materials based on polyester fibers. They differ in their density, which also affects how they retain heat. It all depends on how the padding is made: the threads can be woven in different ways, and sometimes manufacturers add additional structures.

Polyester has many properties:

- The temperature range at which polyester filling can be worn is from 5 to 30 degrees below zero.

- Clothing with synthetic insulation does not harbor pathogenic bacteria, so even allergy sufferers can wear it.

- Things retain their original shape for a long time and are not subject to deformation after many washes.

- The jacket's filling does not require special care; it is easy to wash in an automatic machine.

- Down jackets weigh little, making them comfortable for people of all ages.

However, at temperatures above 40 degrees Celsius, the fibers become deformed. Inexpensive material may become crumpled after 3-4 washes. In addition, air does not circulate well through such material. The insulating layer is deformed upon contact with fuel, acetone and other compounds containing caustic components.

How to care for clothes with polyester filling?

Whatever the insulation, it requires special care. How the insulated product is washed, dried and ironed directly determines its thermal insulation properties. If you properly care for warm clothing, strictly following all the manufacturer’s recommendations, you can not only preserve its original qualities, but also extend its service life. Caring for a product with polyester insulation involves following the following recommendations:

- Wash by hand or in a washing machine. If a product is allowed to be washed, this does not mean that it can be done every day. This should only be done when it becomes dirty. No matter how high-quality and wear-resistant the insulation is, frequent washing will sooner or later lead not to loss, but to a significant reduction in its thermal insulation qualities.

- When washing in the washing machine, place several tennis balls in the drum. This measure will prevent possible dumping of the filler.

What are polyester insulation

These are thermal insulation materials used at various stages of repairs and house construction. The material is produced by thermal bonding of polyester fibers without adhesives.

The insulation thread is similar to a spiral and consists of many intertwined fibers that “spring”. It is this feature that almost prevents the canvas from deforming, maintaining its elastic properties.

In essence, polyester insulation is a synthetic but environmentally friendly textile. The same PE fibers are used to fill pillows, blankets, carpets, children's mattresses, jackets, and toys. The difference may only be in the thickness of the threads and other characteristics that are insignificant for the user.

Opinions of developers, professional builders and chemists - negative points

Types of modern insulation

I found an interesting article on a website on labor protection in the chemical industry. The influence of polyester resin on the human body and safety measures at work are being studied. What they warn about:

- Polyester resin bonds the fibers together to provide water-repellent and strength properties. When working with resins, safety precautions must be observed. Does this resin disappear or remain in the finished building material? Manufacturers do not answer this question.

- Polyester resins cause respiratory irritation. It is mandatory to wear a respirator when working in production. When the insulation is heated, do resin vapors not escape from the sheathing?

Production volumes speak volumes

- Fire safety - with free access to air and sunlight, spontaneous combustion is possible. You cannot extinguish the resin with water; you can only intensify the combustion. A gas fire extinguishing method is required. This means that fire retardants are obviously added to the insulation to ensure G-1 flammability standards, and these are chemical additives.

- If the resin gets on the skin, the instructions warn about the danger of redness and rash. It is necessary to urgently rinse with water, work in gloves and protective shoes and overalls. Why, since these insulating materials are easy to install and are not hazardous to health?

- Polyester resin is a strong irritant to the mucous membranes. Wear safety glasses. The question arises - where do these resins disappear from completely safe polyester insulation?

Main technical characteristics of the material

It is not surprising that it is difficult to find information about the production process of this building material. Protection of production know-how and other reasoned methods to hide the detailed composition of the material.

A few words about static electricity

Are static discharges really safe?

Polyester fiber is a dielectric and practically does not conduct electric current. That is why the surface of such a material quickly becomes electrified. Everyone is familiar with the tiny sparks in the dark when you take off synthetic clothing.

It is this property that is inherent in all polyesters. Static electricity accumulates on the surface.

The impact of static electricity on health is the topic of a separate dissertation. Basically, these are fatigue, absent-mindedness, and weakness. And long-term exposure causes a number of serious side effects. If you wish, you can find a lot of information about this on the Internet.

Now the question is whether polyester fiber insulation has the same properties to accumulate static on the surface. Has this been studied in laboratories, and what consequences can a long-term stay in a house with such insulation cause?

I will not say that polystyrene foam or mineral wool will do absolutely no harm. But at least the mineral wool boards are natural fibers and not recycled plastic bottles.

Another interesting fact. Is it possible to position this material as natural if it is made from PET bottles?

Of course, ideally, everyone strives for environmental friendliness and natural materials, but they are not affordable for everyone. But why is the cost of synthetic material equal, or even higher, than for natural types of insulation? In theory, polyester fibers should cost pennies.

The author's opinion, which does not claim to be the ultimate truth

World market of synthetic fibers

It so happened that I had to do a lot of construction work around the house with my own hands. I won’t say that laying mineral wool is a pleasant and comfortable process. Polystyrene foam is much more convenient to install.

By the way, thermal insulation made of mineral wool with a protective screen made of foil has now appeared; installation has become simpler and does not require protective gloves and overalls.

I am for preserving nature and not littering it with mountains of plastic bottles and bags. But only one thing is surprising. The production of new generation insulation uses recycled materials, so why can’t it be sold at an affordable price? After all, there is no need to graze flocks of sheep and harvest flax, simple recycling of plastic containers.

It is also strange that not all manufacturers provide fire safety certificates. I’m not even talking about harm to health; the old Soviet GOST standards have long been completely forgotten.

You’ll soon just have to forget about natural materials

It is also interesting that in just two years the growth rate of synthetic fiber production has almost doubled. This year alone, the production of polyester fibers in Russia increased by 69 percent, with an upward trend towards the end of the year.

I don’t know, maybe I’m not a modern person, but I would like to live in a house made of natural materials and eat natural food. Today it is very difficult to find out what percentage of natural ingredients are in food, and what to say about building materials.

I would not be surprised if many objections to this article and arguments in defense of new technologies appear in the comments. But it seems to me that our world is trying too quickly to get away from everything natural and natural. Soon it will be difficult to find natural ingredients in the modern human body.

Polyester insulation: a “warm coat” for your home

Modern insulation made from polyester fibers will help maintain home comfort even in the most severe frosts.

What is home comfort usually associated with? Of course, with warmth! In winter clothing, modern fillers based on polyester threads, which reproduce the structure and properties of fur, help preserve it. Manufacturers have adopted their best properties and entered the market with new insulation materials.

Polyester fibers - what are they?

Scientists became interested in the use of polyester for the production of high-quality and inexpensive insulation materials back in the 80s of the twentieth century. Experiments continue to this day: specialists are developing new combinations of materials and improving the quality of the final product.

For production, the polyethylene terephthalate melt is drawn through special molds - dies. The result is fibers - parallel or multidirectional, which become the basis of the primary fabric. Next, a multi-stage processing process begins - combing, cutting, mixing, bending, twisting, adding antistatic agents and other procedures. As a result, the fibers acquire final consumer properties.

Polyester fibers can be of different thicknesses, densities, textures, and types of twist, which gives the material its individuality and allows it to be used in different industries. Today, polyester insulation is most widely used in construction and light industry (clothing). In terms of popularity, they are not inferior to traditional materials made from natural and synthetic raw materials, and in many respects they significantly surpass them.

Advantages

The first thing that worries a buyer when choosing insulation for a home is the thermal conductivity coefficient: the lower it is, the less heat is consumed. So, for polyester materials, due to their high porosity, this indicator is 0.029–0.031 W/(m * °C). For comparison: for mineral wool, depending on the type (basalt, slag, stone), this coefficient varies from 0.041 to 0.052 W/(m * °C).

What filling for jackets and promotional vests is most often preferred?

A draft at the cash register, or constant movement from the premises to the terrace of a restaurant or cafe can provoke ARVI among staff. It is better to equip employees with suitable clothing in advance than to urgently look for someone to “plug holes” in the work schedule.

Ask a Question

People most often order holofiber vests from us and argue that:

the material is inexpensive; easy; perfectly warms; and also does not absorb odors, which is important, because clothes smelling in the smoking room will spread a stale smell.

Sintepon is inferior in quality to holofiber; it:

- electrified;

- worse air permeability;

- can absorb unpleasant odors;

- warms better than natural materials, but worse than holofiber.

Usually, workwear made from holofiber, including jackets and vests, is dry-cleaned, but washing it yourself in a machine at a temperature of 30°C is acceptable and will not harm the product.

It is important to take into account temperature standards, because the density of the holofiber determines at what temperature it will be most effective

| Holofiber density | Minimum operating temperature | Maximum operating temperature |

| 100 g/m2 | +5°С | +10°С |

| 150 g/m2 | -10°С | +5°С |

| 200 g/m2 | -20°С | -10°С |

| 300 g/m2 | -30°С | -20°С |

Polyester fiber insulation

Polyester fiber insulation is created using the technology of thermal bonding of polyester threads, without adding any other substances, including adhesives. The first padding polyester products included adhesive additives, but more advanced holofiber does not contain anything except polyester threads twisted in a special way like springs. Considering the absolute environmental safety of PE products (it’s not for nothing that children’s mattresses and pillows are made from them), polyester insulation can be considered a worthy alternative to natural ones. Inside the house and outside, in the interior and when cutting a cobblestone or log house - PE insulation has a reputation as absolutely safe materials.

Construction holofiber

PE threads and the insulation materials created from them have their origins in textile technologies (fillers for warm winter clothes, blankets, and so on). But a building board is a much denser and “rougher” thing compared to a children’s air mattress, and therefore is made from thick and dense PE threads, although the predominant twist is spiral, as in holofiber.

The main advantages of polyester insulation:

- Excellent sound insulation. An attic with PE insulation becomes the quietest place in the house; you can’t even hear the rain on the roof.

- According to the main parameter of insulation: the thermal conductivity coefficient of PE materials Kt = 0.029 - 0.031 W/m*deg K, which is slightly better than that of mineral wool.

- Vapor permeability.

- Frost resistance. Low water absorption (less than 1%) gives both the advantage of frost resistance and the ability to store rolls under light cover.

- Does not create cold bridges. One of the few mounted insulation materials that create an almost monolithic coating without equipment for foam, blowing, etc.

- Biostability is absolute, fungus and mold are impossible. Does not contribute to wood rotting due to accidental moisture and corrosion of metal elements.

- Good tensile and compressive strength, elastic properties.

- Environmental safety, hypoallergenic insulation, can be used both indoors and in children's rooms.

- Light weight, easy to use, virtually no waste.

- It is safe to install - it does not generate dust, it fits equally well on any surface, at any angle.

Polyester inter-crown insulation

Intercrown holofiber is called a new generation of insulation. Depending on the type of felling, tape and roll holofiber are used. Installation is extremely simple, the light and airy insulation literally fits itself into the joints and gaps and perfectly fills the voids. But with all the advantages of PE insulation, it has not yet passed the final test of time.

Fire retardant is justifiably added to insulation for wooden houses, which reduces environmental characteristics. From reviews of private builders, it can be noted that there are cases of changes in the color of debarked logs, and sometimes blackening is observed at the joints. In addition, PE insulation is far from the cheapest material.

Summing up

When choosing clothes, for example, overalls, you need to understand: the properties of different types of insulating materials differ by a maximum of 20%. The main thermal insulator is air. Advertising slogans that a thin, expensive insulating lining will keep you as warm as four layers of cheap insulation are an attempt to deceive the buyer. What makes children's clothing warm is the thickest possible layer of bound air mass. Of course, products with a thin insulating insert are easier and cheaper to make. Advertising will try to convince the parents of a freezing child of the usefulness of innovative space technologies. Don't be fooled! Evaluate advertising appeals wisely.

Advantages of Lighttek and Shelster Ecostroy insulation materials

To produce these insulating materials, polyester fiber is used. Polyester is actively used in our lives to create dishes, water containers, furniture, insulation for clothes, toys, etc. Now polyester fiber is also used to insulate their homes.

The advantages of Lighttek and Shelster Ecostroy insulation are as follows:

- Environmental friendliness and safety.

- High quality.

- Elasticity. Polyester fibers are long and elastic. They do not break when mechanically applied to them, and have a certain spring effect.

- Flexibility. These materials can be used to insulate places that are difficult to reach.

- Not afraid of contact with moisture. If polyester insulation gets wet, after drying all the characteristics and their dimensions will be restored again. If, for example, glass wool insulation gets wet, it will be impossible to use it in the future as insulation.

Unlike other modern thermal insulation products, polyester fiber insulation has a number of advantages:

- Ecologically pure;

- High levels of protection from noise and cold;

- It is not subject to deformation, which significantly extends its service life;

- The density and elasticity of the material facilitates the installation process;

- Does not absorb moisture;

- Durable and has unlimited use;

- Can be used repeatedly;

- Easy to use (no special protective equipment required);

- Resistant to mold and mildew.

Due to its qualities and resistance to negative factors, polyester insulation is widely used in almost all areas of construction. We produce several types of thermal insulation from polyester fiber, which differ in their parameters and are ideal for insulating a particular surface.

RosEcoMat Polyef Horizon

This insulation consists of hemp and polyester fibers.

Application: Thanks to the natural antiseptic in the composition, this type is suitable for insulation and insulation of interfloor ceilings and floors. Hemp fiber prevents rotting processes.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 10 kg/m3 |

| Thermal conductivity | W/mK | 0.034 |

RosEcoMat Polyef Vertical

This insulation will become an indispensable material, since installation does not require special skills.

Application: Insulation is used for thermal insulation of frame walls and interior partitions. The structure of the board allows it to absorb sound well and prevents the formation of condensation and mold. The natural component (hemp fibers) reliably protects surfaces from the effects of negative factors.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 20 kg/m3 |

| Thermal conductivity | W/mK | 0.036 |

RosEcoMat Polyef Slope

This material is actively used in construction.

Application: The very name of the insulation indicates that this material’s parameters are ideal for insulating attic roofs and roofs. The insulation also copes well with the problem of heat and sound insulation of floors on wooden beams. RosEcoMat Polyef Slope can be used and is suitable for insulating from sounds outside the house, such as the sound of rain or sounds from passing vehicles.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 16 kg/m3 |

| Thermal conductivity | W/mK | 0.033 |

RosEcoMat Polyef Antisound

Hemp is antibacterial and works great against mold and mildew problems.

The polyester composition does not absorb moisture, so condensation and surface deformation are excluded. Application: The parameters of this type of polyester insulation are designed specifically for soundproofing premises (interior partitions and floors). In addition to polyester fiber, the board contains hemp fiber. It is this composition that makes it possible to safely use this type of building insulation in residential premises.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 20 kg/m3 |

| Sound absorption coefficient | 0,98 |

RosEcoMat Polyef Roll

RosEcoMat Polyef Roll is an insulation material produced in rolls, which is convenient for installation, especially during the construction of low-rise residential buildings.

Application: Safe insulation made from hemp and polyester fibers is environmentally friendly, which is perfect for insulating residential buildings, as well as insulating saunas and baths. Due to its increased environmental friendliness, this insulation is often used in medical and children's institutions. The service life of the material is up to 150 years, and due to the high energy savings, you can save a lot on your purchase.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 6000 |

| Width | mm | 1200 |

| Thickness | mm | 50 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2 |

| Thermal conductivity | W/mK | 0.036 |

| Specific heat | J/kg K | 1550-1600 |

| Sound absorption coefficient | NSV-211 | |

| Coeff. vapor permeability | mg/(MhPa) | 0,33-0,37 |

| Compressive strength | kPa | 1-2 |

Insulation made from polyester fibers from the best domestic manufacturer RosEcoMat is a contribution to the comfortable atmosphere of your home and concern for the health of your loved ones.