In the modern world, there are a number of problems associated with choosing suitable clothing, namely, one that fits perfectly on the figure. To do this, they use different cuts, patterns, fitting and other methods.

However, there is a fabric that can be easily processed and is able to fit closely to body shapes and is stretchy and resilient. It's called stretch . It simplifies the work of seamstresses and has a number of its own features, and it is also very similar to synthetic knitwear.

origin of name

The origin of the name stretch comes from the English word “stretch”, which means to stretch, to stretch. Therefore, we can assume that both ways are correct.

Stretch is a fabric that has an elastic structure due to the addition of synthetic fibers such as lycra and spandex to the material. The stretchability of the stretch depends on the proportion of elastic threads contained in the material.

Stretch characteristics:

- Elasticity and smoothness. They help to fit any figure and emphasize the structural features of the body.

- Strength and stability. Since the material is elastic, it does not tear, which increases the period of wearing clothes.

- It allows air to pass through well, which promotes normal sweating.

- Hygroscopicity. Absorbs moisture well.

- Does not cause allergies. The fabric does not cause any allergic reactions at all, which is a positive feature for people who are prone to such reactions.

- Possibility of long-term use of fabric.

Advantages

- elasticity and strength

- extensibility

- crease resistance

- keeps its shape perfectly

- does not fade or change appearance when exposed to direct sunlight

- high levels of warmth and air conductivity

- good hygroscopicity

- easy to wash

Application

Stretch fabrics are especially valued in clothing. In addition, the elastic material looks great in furniture upholstery and home textiles.

- All types of women's clothing: dresses, skirts, blouses, jackets;

- Tight and tight trousers, jeans and leggings;

- Dresses for special occasions;

- Sportswear, suits and tights;

- Men's shirts and jackets;

- Dressing for theater and circus performers;

- Underwear items;

- Swimwear for children and adults;

- Socks and knee socks;

- Women's stockings and tights.

Fabrics for sewing bedspreads, covers, decorative pillowcases and capes are made from fabrics with the addition of spandex. The pliability of the material makes it easy to obtain the desired shape.

Main classification

Often stretch is made from a mixture of different fabrics . Let's consider several variations:

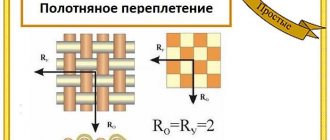

- Bi-stretch is a fabric that can stretch in both directions. This is possible by adding elastic threads in two directions.

- Mono-stretch - stretches in one direction only. Threads are added in one direction only.

- Stretch jeans (also called denim) are characterized by their density. Used for sewing denim clothing. To make a durable material, polishing is necessary.

- Satin is a dense fabric with a smooth structure and a glossy sheen. Often used for sewing evening dresses and various carnival costumes.

- Velvet is a knitted fabric with a fleecy base, which also has a glossy sheen and a dense structure. Essential for sewing tight-fitting evening dresses.

- Satin is a stretch material with a very strong thread structure. It is usually used for sewing children's clothing.

- Jacquard is a dense material with a characteristic pattern. Necessary for sewing women's and men's suits.

- Gabardine is an elastic fabric with a characteristic scar-shaped pattern.

- Leather - this fabric can be either artificial or natural. The peculiarity lies in the processing and sewing technique, as well as the elasticity of such material.

- Velor is characterized by the presence of dense pile on the surface, which has a pleasant and soft structure to the touch.

- Viscose - when combining two of these fabrics, you can get a dense, opaque material that will have excellent resistance to deformation and good drape ability.

- Cotton stretch is a dense material that has its own characteristics. Mixing stretch and cotton led to improved properties of the material. Nowadays, cotton knitwear is often used to make various clothes, it is universal in its structure, and has many advantages.

- There is also such an unusual fabric - barbie. The description of the material is quite simple. The material consists of cotton and elastane, the structure is a bit like jeans. The name comes from the color, “like the outfit of a Barbie doll.”

How to write correctly: stretch or stretch?

Information from the Internet does not allow you to clearly understand how to spell: stretch or stretch. This word is presented in several variations: sketch, stretch and many others. The original meaning is interpreted as stretch (“stretch”), so it is correct to write and say stretch, but such pronunciation is difficult for Russian speakers.

Wikipedia and other authoritative resources reproduce many options for how to spell stretch correctly. The final choice is always made by consumers of stretch film; in addition, search engines always create hints and pictures when a query is entered incorrectly.

Product care requirements

In order for the purchased item to retain its qualities and also remain elastic, the following care requirements must be met:

- Wash only in gentle cycle.

- The washing temperature should be no more than 30 degrees.

- When drying clothes, it is unacceptable to expose them to sunlight.

- When ironing fabric, you must carefully and accurately move the iron over the fabric and use it at a temperature of no more than 100 degrees. Do not use steam for smoothing.

Characteristics

Read about: Grodetour fabric: the sedate dignity of the past.

Elastic threads in the material give it the following characteristics:

- extensibility.

- It can be in both directions or just one. Allows clothing to fit properly.

- strength.

- Elastic fibers give the material tensile strength and increase its durability;

- resistance to deformation.

- Elastane fibers are able to stretch and return to their original form, due to which the material also does not stretch, does not stretch and holds its shape well;

- wear resistance.

- The products are wear-resistant and retain their characteristics for quite a long time.

For example, elasto-multiester in jeans allows the product to stretch 1.5 times. This is a wonderful property, especially since the jeans on the body immediately return to their original state.

At the same time, the presence of fibers of synthetic origin in the composition of the material does not prevent the manifestation of all the advantages of natural fibers due to the small percentage of content. That is, stretch denim retains all the positive properties of cotton fabric - breathability, hygroscopicity, hypoallergenicity.

Read about: Manchester - a fabric that gives comfort.

Flaws:

- The only drawback is that the material gives a fairly large percentage of shrinkage, but if all care recommendations are followed, this disadvantage can be minimized.

Flaws

A significant disadvantage of stretch is its tendency to shrink. If the rules of care are not followed, the material shrinks greatly without the ability to return to the desired size. That is why manufacturers strongly recommend strictly following all the rules specified in the accompanying label.

In addition, any stretch fabric contains a synthetic component. Sometimes it is quite small (only 1-5%), sometimes, on the contrary, it is noticeably a lot - 20%-30%. This additive may cause allergic reactions in people with sensitive skin. That is why stretch should be treated with due attention, always carefully studying the composition.

If you are prone to negative manifestations (itching, redness, irritation), it is better not to take products with synthetics that are directly adjacent to the skin (underwear, tank tops, leggings, socks, etc.). In this case, give preference to 100% natural fabrics.

Manufacturing process

Important. Lycra, spandex and elastane are segmented polyurethanes from the group of artificial elastane fibers. Their structure consists of flexible segments connected by rigid connections. Thanks to this structure of polymers, their soft segments do not tear and provide elasticity to the material.

There are the following methods for obtaining them:

- polymer melt extrusion;

- dry, wet and reaction molding.

Types of film from an automation point of view

All stretch films are divided into two large classes - for manual and machine (automatic) use. If manual material is used to work with manual unwinders or dispensers, then machine stretch film is installed on automatic pallet packers.

Manual film differs from machine film in its characteristics and, above all, in the value of pre-stretch. This parameter shows, as a percentage, how much the film material can stretch without damage and while maintaining its basic properties. The pre-stretch value of hand-wrapped film is usually below 100 percent; for machine-wound film, pre-stretch is possible from 100 to 300 percent or higher.

It is believed that when palletizing non-essential cargo of simple shapes, the use of manual film is allowed, and machine film should be used in more complex cases. However, in practice, the question of choice depends on the presence or absence of an automatic pallet packer or pallet wrapper at the enterprise.

Description of tissue group

The term “stretch”, or more precisely “stretch”, is of English origin “stretch” and means “to stretch”. This means that stretch is all types of stretchy fabrics. For example, stretch cotton is a material containing from 1 to 30% elastane, lycra or spandex. In addition to hygiene, hygroscopicity and breathability, it acquires new advantages.

The presence of elastic fibers in stretch cotton:

- makes it easier to sew tight-fitting clothes from it;

- increases the wear resistance of natural products;

- helps maintain shape.

Stretch yarn in jacquard or capricious silk allows stretched items to take their original shape. Stretch denim containing up to 30% synthetics is especially popular.