Types of knitted fabric by weaving

- Kulirka . The thinnest knitwear. The front side consists entirely of braid loops. On the reverse side - all the loops are purl. The front surface is smooth, the material is the thinnest among the canvases.

- Interlock . It has two front sides, both covered with “braids”. The material is used in the production of children's clothing. It is distinguished by comfortable softness and moderately voluminous structure.

- Footer . Favorite material for tracksuits. On the front side it is covered with loops of “braids”. There are two types of footer:

- on the wrong side there is a “bouffant”, the material is dense and warm;

- wrong side – covered with air purl loops. Thinner material is used for summer sportswear.

Both types of footer are much denser than other types of knitted fabric.

- Pique . It looks like a waffle towel, but unlike it, it has the stretchability characteristic of knitwear. Used to make summer T-shirts with polo fasteners.

- Kashkorse . Low-cut sports trousers, cuffs, trowel collars – all this is cash-corse. The material is dense, made from cotton, wool, mixed fibers, knitted in the form of an elastic band - knit plus purl loops 2x2, 3x3.

- Ribana . Knitwear similar to cashkorse, only with a smaller pattern, knit and purl loops 1x1. Used for summer clothes or as cuffs, collars.

- Jersey . Dense wool material, does not wrinkle, stretches in the transverse direction. Even with the addition of other fibers, it does not lose its properties. A favorite material for women's dresses, skirts and suits.

- Knitted mesh . Widely used for lining, sportswear and underwear. Conducts air well.

- Biflex . The interweaving of threads takes place in two directions - horizontally and vertically. Made from synthetic fibers. The main difference is elasticity in two directions. Used for sportswear.

- Lycra . In its pure form, the material is not strong enough; it can be transparent or translucent. It is characterized by strong elongation, with virtually no residual deformation. In clothing it is used in combination with other fibers.

Classification and characteristics of the assortment of knitted goods

Knitted goods are the “clothing of the century” due to their elasticity, stretchability, softness, resilience, and high aesthetic properties. The range of knitted goods is classified as follows:

- by purpose: for outerwear, knitted underwear, hosiery, gloves and scarves, hats;

- by raw material composition: into homogeneous (cotton, linen, wool, chemical fibers and threads) and heterogeneous (a combination of various fibers and threads);

- according to the type of knitted fabric used: cross-knitted (knitted) and warp-knitted;

- according to the production method: into whole knitted (obtained in one go), knitted (joined from knitted parts), cut (using fabric patterns) or combined, combining knitted and cut parts;

- by gender and age: men's, women's and children's;

- by type: for a sweater, jacket, jumper, stockings, socks, long johns, T-shirts, etc.;

- by finishing: bleached, plain-dyed, printed, variegated, melange, etc.;

- by season socks: for summer, winter, demi-season, off-season;

- according to sizes determined similarly to garments.

Outer knitwear occupies a leading place in the range of knitted goods in terms of the variety of raw materials, types of weaves and finishing. The following types of products are produced: coats, capes, jumpers, jackets, vests, sweaters, dresses, suits, trousers, leggings, blouses, dressing gowns, overalls. The design of coats, dresses, skirts, trousers, capes, blouses, dressing gowns and overalls is similar to sewing products.

Jumpers are products without a cut or with a cut that does not reach the end of the waist. Available with or without a collar, with long, semi-long, short or sleeveless sleeves, with or without pockets.

Jackets are products with sleeves and a slit along the entire length of the waist. They produce women's and men's, with sleeves of different lengths, with and without belts, collars, pockets.

Sweaters have a high single or double collar with or without a lapel, tightly covering the neck, with sleeves of various lengths and designs: raglan, sewn, one-piece.

Leggings are knitted or cut knitted outerwear that is made with long and short legs.

, knitted underwear is divided into household and sportswear. Household underwear is divided into men's, women's and children's.

Men's underwear includes sweatshirts and long johns in the form of sets or individual items. Sweatshirts consist of a front, back and sleeves of varying lengths, with or without a fastener. Long johns consist of two legs and a gusset, and can be long or short.

Women's underwear is more varied than men's. It includes women's shirts, pantaloons, negligees, slips, nightgowns, sets and petticoats. Pantaloons consist of two legs and a gusset; there are short, long and pantaloon pantaloons. The combinations come with straps, strapless and sleeves. The edge of the top and bottom of the combination is decorated with lace, ruffles, trim, piping, etc. Embroidery, applique, thermal printing, etc. are also used as decoration. Nightgowns are made long and short, of three types - with sewn-in sleeves, with one-piece or raglan type, sleeveless.

Children's underwear for boys and girls differs from underwear for adults in the types of products and raw material composition. Products for toddlers (including newborns) include baby vests, sandboxes, rompers, overalls, envelopes, hats, etc. Baby vests are sewn in the form of a loose blouse with straight, usually short, one-piece or sewn-in sleeves, with a through slit in the front. Sandboxes can be one-piece, with a sewn-on or clip-on bra, with straps and bibs, with pockets and without pockets. Sandboxes are also produced in the form of a set - short, strapless pants with a blouse. The overalls are made with a one-piece bodice and trousers or with a bodice cut along the waistline and with a longitudinal slit. Hats and bonnets can be made up of two, three or four parts. From the listed products, sets can be made that include two, three, four or more items. Produced from materials containing predominantly natural fibers and threads.

Sports underwear is represented by sports shorts, sweatshirts, T-shirts, swimsuits, etc.

Hosiery products are produced in the following assortment: underwear, socks and half-stockings for men, women and children, women's stockings, sports stockings, leg warmers, tights for women and children, household and medical.

They are worn in the summer instead of socks and are made mainly from nylon elastic threads.

Socks differ from stockings in that they are shorter and have an eraser (elastic band) instead of a side. The sizes of men's, women's and teenage products are designated by odd numbers, and children's sizes by even numbers.

Half-stockings are produced knee-length with a short side, into which a rubber band or vein is embedded. The main parts of a woman's stocking are the side, leg, heel, trail and toe. They produce women's, men's and children's. Stocking size is the length of the mark in centimeters. As the length of the trace changes, the size of other parts of the stocking changes slightly. They produce stockings and half-stockings in white, plain-dyed, variegated, printed, embroidered, etc.

Women's stockings cover the foot, lower leg and thigh. They are produced on circular hosiery machines and cotton machines from synthetic threads or a combination of different types of yarn and threads. The top edge of the stockings may have lace trim. Distinctive features of stockings made from cotton machines are the presence of a seam running along the entire length of the print and the leg of the stocking from the toe to the top of the side. In stockings from round hosiery machines there is no seam or there is a false seam running along the leg to the low heel, the ends of the reinforcing loops are visible along the mark on the wrong side. The quality of stockings from cotton machines is higher than those from round machines. These stockings have a more stable shape and fit the leg beautifully.

Sports stockings differ from regular stockings in their shorter length (to the knee) and the presence of an elastic side. The leg of such stockings is smooth or with a relief pattern, the top ends with a side with a rubber vein or cuff.

Gaiters are stockings without a heel or trace. They cover the lower leg and sometimes the thigh.

Gloves and mittens are divided into sewn and knitted, winter, demi-season and summer. A separate subgroup consists of theatrical gloves. Based on gender and age, gloves and mittens are divided into men's, women's and children's. Can be with or without clasp. The size of the gloves is equal to half the circumference of the hand, measured in the middle, between the bases of the thumb and index finger, in centimeters. Knitted gloves and mittens are made single and double, with or without a fastener.

Shawl-scarf products and headdresses are represented by the following types: scarves, shawls, hats, stoles, headsets, etc. Stoles are scarves 1.5–2 m long and at least 50 cm wide. Hats are produced in various designs. Sets can combine various products, united by finishing, raw material composition and other characteristics.

Interlock

Interlock is often called “dvulastic”; it is a knitted fabric with an “elastic” structure. Smooth on both sides. Doesn't stretch. Doesn't bloom. Resistant to deformation. Warm. Good air permeability. Effective. Used for sewing knitted underwear, light summer clothes, shirts, sportswear, children's clothing. 100% cotton.

- Cashkorse fabric with many varieties: their features and applications

CLASSIFICATION AND RANGE OF KNITTED GOODS

Classification of knitted products

The wide range of applications of knitted products and the variety of requirements placed on them, depending on their purpose, necessitate the production of products in a large and varied assortment.

Currently, some types of clothing, such as stockings and socks, and lingerie, are made entirely by knitting. About 75% of all underwear and a significant part of outerwear are produced from knitwear. In addition, knitwear is used in technology (as filters, gaskets, frames), in industry: footwear (as a lining for rubber shoes and a reinforcing layer of artificial leather), haberdashery (in the production of lace, curtains and corset materials using the knitted method), carpet (in the manufacture of knitted carpets), as well as in medicine (for the manufacture of knitted bandages; blood vessel prostheses), in network knitting and other industries.

All knitted products are divided into household products and technical knitwear.

The range of household knitted products is divided according to the following characteristics: purpose, manufacturing method, type of raw materials used, finishing method and weave structure.

According to their purpose, knitted products are divided into five classes: 1) underwear, 2) outerwear, 3) hosiery, 4) gloves, 5) hats and scarves.

Each class contains groups of products, divided by gender and age. For example, in the underwear class there are groups - men's, women's and children's underwear; in the hosiery class, socks are divided into men's, women's and children's, stockings - into women's and children's.

Some groups of products are divided into subgroups depending on the seasonal purpose of the products; for example, the group of women's gloves contains three subgroups: winter, summer and demi-season products.

Within each group or subgroup, products are divided by type, i.e., by product names. Thus, in the class of underwear, the group of men's underwear contains the following types of products: sweatshirts, briefs, T-shirts, shirts, etc.; group of women's underwear - pantaloons, sets, combinations, etc.; troupe of children's underwear - shirts, panties, T-shirts, knickers, sandboxes, rompers, etc.

In the class of outerwear, the men's group contains: jumpers (pullovers), vests, sweaters, jackets, etc.; women's group - jackets, jumpers, dresses, suits, etc.; children's group - jackets, jumpers, sweaters, coats, jackets, overalls, etc.

The class of hosiery products includes the following types of products: stockings, half-stockings, leggings with a trace, leggings, socks, underfoot; class of glove products - gloves and mittens; class of headdresses and scarves - hats, berets, balaclavas, scarves, scarves.

Types of products are divided into types, which determine the design features of the product. For example, GOST 2106-61 provides for three types of pantaloons: long, short, pantaloons; Blouses are produced in two types: a blouse for tucking into a skirt, a blouse for wearing untucked.

Each product type contains several SKUs. An article is a symbol in the form of a number (code) attached to the name of the product.

The product article characterizes the style (or group of styles), the type and number of yarn from which the fabric of this product is made, the structure of the fabric and the type of machine on which it is produced.

In the current price lists for knitted products, product articles are indicated by five- or six-digit numbers, in some cases they are supplemented with letters.

The first two characters indicate the type of product, the third character - the type of raw material from which it is made, the fourth character - equipment (type of canvas), the subsequent characters indicate the serial number of the products in the price list.

Letter designations are introduced additionally when using special types of finishing of the fabric (padding, use of extra-strong dyeing), in the manufacture of products with complex weaves (jacquard, piqué, etc.), in the case of using special types of finishing of products (using patterned and relief trims, decking and quilting when sewing).

For example, a women's shirt (type of product - 13), made from cotton yarn (type of yarn - 0) on an erasing machine (type of equipment - 2) and having a serial number according to the price list - 1, will have article 13021; if this shirt is made from printed fabric, then its article number will be 13021-B. A women's jacket (type of product - 52), made of woolen fabric (type of raw material - on an interlocking machine (type of equipment - 2), having a serial number - 2 and made using squaring of parts over 4 inches, will have article number 52822-E4.

if this shirt is made from printed fabric, then its article number will be 13021-B. A women's jacket (type of product - 52), made of woolen fabric (type of raw material - on an interlocking machine (type of equipment - 2), having a serial number - 2 and made using squaring of parts over 4 inches, will have article number 52822-E4.

According to the manufacturing method, knitted products are divided into cut, semi-regular, regular and combined.

Cut products are sewn from metric knitted fabric having an arbitrary width or a width equal to the width of the product. The latter applies to cross-knit single and double fabrics; in this case, the product is made without side seams. The process of cutting and sewing cut products is labor-intensive; its main disadvantage is significant waste in cutting (20-25%). Outerwear and underwear and some mittens, gloves and hats are made in this way.

Semi-regular products are made from coupons that are knitted to a given length using different weaves for the waist, waist and hem of the sleeves. When knitting with coupons, the bottom of products (waist or sleeves), as a rule, is knitted by machine; their edges, made from one type of weave, are integral with the sleeve or waist, knitted with another weave. In this case, the product does not have seams at the junction of the belt with the waist or the cuff with the sleeve, and there is no need to hem the bottom of the product and the sleeves; all this gives the product a more beautiful appearance. The time for sewing products is significantly reduced; for example, sewing a semi-regular jacket requires 11% less time than sewing a tailored jacket. The costs of the fabric are also reduced due to the reduction in the area of the parts, since the hem of the bottom is eliminated and the allowances for the seam overlock trim are reduced.

Outerwear and underwear for women are made semi-regular; in the latter case, the products are made without side seams.

Regular products are produced entirely on a knitting machine (for example, hosiery, which is sewn along the toe or along the stocking to give it a finished look; gloves and mittens) or are sewn from parts that are completely given the required configuration during the knitting process. The parts are sewn together into a product without undercut or with slight undercut of the neckline, armhole or sleeve cap. With this method, waste is minimal and amounts to 6-8%. Its disadvantage is the higher labor intensity in knitting compared to the production of fabrics for cut products. In this way the upper products are made.

Combined products are a combination of pieces knitted in a regular way and cut from linen or made from coupons. The advantage of this method is the production of minimal waste when cutting, combined with high productivity when knitting. This is achieved by the fact that the sleeves of products, the cutting waste of which has a maximum specific weight, are manufactured in a regular way, and the mills are cut or semi-regular. This method is used in the manufacture of jackets.

According to the type of raw materials used, knitted products are divided into three groups: A—products made from yarn from natural fibers and yarn from natural fibers in combination or mixed with artificial and synthetic (up to 30% inclusive) yarn or threads; B—products made from artificial threads and yarn from artificial fibers, as well as from artificial threads in combination with synthetic threads or yarn (up to 30% inclusive); B - products made from threads and yarn from synthetic fibers, as well as from threads and yarn from synthetic fibers (over 30%) in combination or mixture with natural and artificial ones.

According to the finishing method, knitted products are divided into gray, bleached, dyed, variegated, printed, combed, felted, embossed, finished with suede, with special processing, etc.

According to the weave structure, knitted products are divided into cross-knitted (waist) and warp-knitted, each of which can be double or single.

Knitwear: from manual labor to machine labor

Every person has at least a few knitted items in their wardrobe. Knitwear is very comfortable and soft, it breathes and warms, it does not limit our movements - we value it for these properties and are happy to wear robes, nightgowns and shirts, cozy pajamas, comfortable home suits, home dresses and tunics made from it at home material. So what is knitwear?

The emergence of knitwear

The word knitwear itself has French roots. From the French word "tricoter" - to knit.

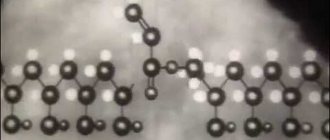

Knitwear is a textile material obtained from one or many threads by forming loops and interweaving them.

The loose loop structure gives knitwear characteristic qualities that distinguish it from other fabrics - elasticity, stretchability and softness.

Since ancient times, people have been knitting things from knitwear. This is confirmed by archaeological excavations, as a result of which stockings for sandals characteristic of the 3rd - 1st centuries BC were found. in Egypt. The appearance of the stockings resembles mittens.

In general, knitting was very popular in ancient times. You can verify this by visiting the museums of Deutrot and Badel, where Egyptian cotton knitted items with Arabic texts are displayed. Knitting is also mentioned in the myth of the Golden Fleece, which tells how Penelope knitted a blanket for many years while waiting for Odysseus.

At first, people knitted on their fingers. It is interesting that the first hand knitting was an exclusively male profession, and only after widespread use did it become a female profession. And only approximately in the 3rd - 5th centuries. BC. knitting needles and a crochet hook were invented.

The first knitting machine

In 1589 in England, the curate William Lee invented a hand-held flat knitting loom. According to the current version, the impetus for this invention was the following circumstance. William Lee had a fiancée, a poor girl who made her living by hand knitting stockings. Work took up so much of her time that she could not go out with her fiancé.

Not wanting to part with his bride, William Lee sat next to her for hours, watching the movement of her hands and knitting needles as she formed the loops. As a result of these observations, he came up with a machine on which he could knit stockings much faster.

What happened in reality is unknown, but it is obvious that by that time the level of development of the productive forces made it possible for William Lee to invent the first knitting machine. This machine was called a kulir machine, since in order to form loops on it, the thread was first bent into loops, that is, kulirovaya.

To obtain loops, William Lee equipped his machine with special hooked needles instead of knitting needles. The needles are fixed on a flat horizontal bar-needle bed. Since then, machines with a flat needle bed are called flat or flat knitting.

In 1755, the Englishman Crann invented the first warp knitting machine, where loops were made not from one thread, but from a whole system of parallel threads.

Improvement of knitting machines

Knitting machine building became more widely developed only in the middle of the 19th century. At this time, a huge number of inventions, improvements and devices were patented. A reed needle appeared, and machines began to be equipped with a mechanical drive.

- In 1755, the Englishman Crann invented the first warp knitting machine with hook needles. In this machine, loops of one row were formed not from one thread, but from a whole system of parallel threads, called the warp.

- In 1798, the first round machine for knitting round knitted fabric in the form of a wide stocking was invented in France.

- In 1847, the Frenchman Townsend invents the reed needle. Circular knitting machines and flat wedge machines are equipped with such needles.

- In 1881, Durand invents the first grooved - tubular needle.

Knitwear in Russia

Knitwear was first brought to Russia by Peter I from Germany, these were knitted stockings. Since that time in Russia, knitting stockings and socks has been developing as a craft.

In 1913, the knitting industry accounted for only 0.6% of the total textile industry.

Russia takes its first steps in this industry only at the end of the 19th century, and until the revolution of 1917 it was of a handicraft or semi-handicraft nature. During the initial period of the First World War, the knitting industry approximately quadrupled thanks to large orders for the army, which it equipped with sweaters and warm sweatshirts.

Subsequently, the imperialist and civil wars led the industry into a state of decline. But in the first year of the end of the civil war it reached its revolutionary level, and by the end of the recovery period it increased almost six times.

During the pre-war five-year plans, the knitting industry developed rapidly, many large knitting factories were built: Ivanteevskaya (Moscow region), Tushinskaya hosiery (Moscow), Vitebsk, Kiev, Baku Aztrikotazh, knitting factories in Novosibirsk, Tbilisi, Kokand, etc. -improved equipment and production technology.

Huge damage

The Great Patriotic War also caused enormous damage to the national economy of the USSR, including the knitting industry. About half of the knitwear enterprises operating at that time ended up in the temporarily occupied territory. From the center of Russia, factories were evacuated to the east, so the Odessa knitting factory began producing products in the city of Kurgan in 1941.

At other factories, the range of knitted products has sharply decreased; Most of the products were intended for the needs of the country's defense, such as underwear for soldiers, foot wraps, scarves, mittens and other products.

Knitting production in the post-war period

After the war, a huge amount of work was carried out to restore and reconstruct knitting enterprises. In that volume, the production of knitwear in 1950 reached military levels, and in 1964, the production of hosiery increased by 2.6 times compared to 1940.

Currently, the pace of development of knitwear production is significantly ahead of the pace of development of other branches of the textile industry.

Gradually, everyone came to the conclusion that the production of knitted clothing is much more economical and profitable for industry, and primarily because knitting production is less labor-intensive than weaving. Clothing made from knitwear is created much faster than fabrics, since its raw materials and materials per unit of production in knitting production are much less.

Accordingly, clothing made from knitwear, which is made from the same raw materials as fabric, is much cheaper than clothing made from fabric. In addition, the fact that not only sportswear, but even dresses, suits, and coats made of knitwear often look much more beautiful, more elegant and, as it were, more modern than the same clothes made of fabric is of great importance.

Nowadays

Currently, the pace of development of the knitting industry has reached a high level.

In the production of knitwear, production lines are increasingly being used, as well as computer-aided product design and process control systems using new information technologies.

The share of knitted clothing is steadily increasing. This is explained by the high technical and economic indicators of the knitting production method (the productivity of knitting machines is much higher than the productivity of weaving machines), as well as a number of significant advantages of knitted products over sewing ones, the main of which are ease of use, good hygienic properties, and wrinkle resistance.

The constant improvement of methods and basic principles of machine-made knitwear and the progressive development of processing technology for the manufacture of knitwear have since led to a high technical and economic level of development, which is also expressed in productivity, in general significantly exceeding modern productivity in weaving.

#fabreex #history #circular knitting machine #flat knitting machine #polyester fabrics #knitwear production #textile industry #knitwear #cotton fabrics

Types of knitted fabrics

I really love sewing from knitted fabrics. They are very soft and cozy, warm and cool, smooth and textured. To make it easier for you to understand the types of knitted fabrics, I present the article:

TYPES OF KNITTED FABRICS:

KULIRKA is a thin, smooth, patterned or openwork knitted fabric, with flat vertical “braids” on the front side and dense “brickwork” on the back side. It stretches in width and almost does not stretch in length. Quite often cotton is diluted with lycra. The quality of this version of the finished fabric is in no way inferior to the usual one, but it increases its elasticity by an order of magnitude, which only expands the boundaries of the use of the material. It is produced plain-dyed, printed, melange. If the cooler is made of cotton or bamboo, then it is used for sewing linen and summer clothes such as T-shirts/blouses and more. At home - loose-fitting robes, feminine T-shirts with wide skirts or shorts; for a walk - light dresses, sundresses or colorful tunics. Comfortable underwear, soft knitted breeches and cropped trousers, men's T-shirts are not all that can be created using a cooler.

NUSSE COOL – a smooth knitted fabric made of synthetic yarn with a brushed surface. It is produced printed and used in sewing jumpers and turtlenecks for women and girls and, as practice has shown, for men too

AZHUR is a thin lace fabric with a through mesh pattern. Used in sewing linen.

ERASER (or RIBANA) is an elastic knitted fabric with a fine ribbed finish (1x1, 2x2). A special feature of ribana is its elasticity, due to the weaving of a rubber thread into the fabric, thanks to which the fabric perfectly holds its given shape. It is produced plain-dyed and printed. Used for sewing summer items. Ribbon with lycra is used as additional details - cuff, collar. It is used when sewing turtlenecks, in particular necklines and cuffs, as well as outerwear. In addition, it makes excellent home dresses, shirts, sleeping sets and much more. A striped or printed ribbed finish on an inconspicuous plain knit surface will complete the look and highlight its individuality.

INTERLOK is a non-elastic knitted fabric with a ribbed or ribbed structure, maybe brushed. When stretched, it returns to its original size. Made from cotton, blended and synthetic fibers; plain, printed or melange. Used for sewing children's suits and jumpers. Interlock also makes excellent pajamas, nightgowns, and T-shirts, in which you can feel the natural silkiness of the fabric fibers even during sleep. Not every Russian apartment can boast a consistently high temperature during the cold season, so when winter comes, it is especially important to be in a constantly alert state. It’s not for nothing that there is an old Russian proverb: “Don’t sleep, otherwise you’ll freeze!” It’s not so easy to freeze in clothes made from interlock, because the material has increased thermal insulation, which means it will keep your body warm and comfortable in any weather. In addition, convenience also lies in the fact that the clothes practically do not stretch or unravel, and this has a beneficial effect on its service life. Nightmares will instantly subside, and sweet dreams will prevail over daily fatigue.

Pique is a dense fabric, the front side of which has a textured design (honeycomb). Made from cotton fibers in a combined weave. Pique is available in two types: plain-dyed and with a “combed” pattern on the reverse side. Used for sewing sportswear and children's clothing. The shirts worn by the managers from Eldorado are exactly from this.

VELOR is a medium-density knitted fabric with low, very thick and soft pile, obtained by knitting additional threads into the ground to form a looped pile. Loop pile is cut on one or both sides of the fabric, resulting in a dense, soft, velvety, well-draped fabric. The name “velor” comes from the French word velvet, because. the material has a soft pile, velvety surface, it is luxurious and cozy. Available with a smooth surface, raised or ribbed. It is advisable to use knitwear such as velor for those products in which it is necessary to combine external attractiveness (bright colors, pleasant texture) with warmth and durability. Velor is successfully used for sewing a wide variety of types of clothing: from children's and homewear (pajamas and dressing gowns) to sportswear and sweatshirts.

FOOTER is a dense and medium-density fabric, smooth on the front side and sometimes backcombed on the back. Plain dyed, printed and melange are produced. Bright colored dresses, rompers, trousers, elegant overalls made of 2-thread fleece fleece are the right things for modern and fashionable children. Of course, the fabric is not aimed at any particular category of consumers, so footer is also used when sewing clothes for adults. This material makes excellent warm clothes, underwear, bathrobes, etc. A warm sweater or sweatshirt made of thick 3-thread fleece will not only warm you up in cold weather, but will also give your body a pleasant feeling. It's all about the inner layer of this fabric, which most often consists of combed pile. Since it is a natural material, the footer is able to allow air to pass through, which is also of great importance for absolutely any skin. A 2-thread fleece robe with brushed footer will help you immerse yourself in the comfort and warmth of home. Sportswear made from footer is no less popular. It usually uses a thin 2-thread footer with Lycra. The fabric is strong enough to withstand the stress of physical exercise; in addition, even the most intense movements will not cause kinks or wrinkles on your favorite sports item. .

FLEECE is a voluminous, warm, synthetic fabric with a fleece on the front and back sides. It is produced plain-dyed, printed, and is used for sewing hats, scarves, dressing gowns, jackets, home sets, men's trousers, as a lining for jackets/pants.

CAPITONE is an insulated, three-layer knitted fabric with a diamond-shaped stitch effect. It is produced plain-dyed and printed. Capiton is used for sewing children's robes and sets for newborns.

MILANO is a durable, warm and very cozy knitted fabric made from viscose. Therefore, we can say that it has all the properties of viscose, but at the same time it is distinguished by additional softness and tenderness when touching your body. In order for the properties of this material to meet the highest requirements, it combines several threads, each of which gives this material properties that are optimal for its long-term use: these are viscose, lycra and nylon. This fabric received its name in honor of the Italian city of the same name, and given that it was created and developed in Italy, this fabric was originally intended for sewing stylish and fashionable things. Until now this has remained unchanged. You can sew anything from Milano. ranging from dresses and jackets to tracksuits. Products made from such material should be washed in a gentle cycle and at low temperatures (30-40 degrees) - then they will serve you for as long as possible and will not stretch out or fade.

The quality of knitted fabrics is: openend, carde (ring), pene. to put it simply, on a five-point scale it will be “3”, “4”, “5”, respectively.

You should always remember that absolutely any thing requires careful handling, and it doesn’t matter what material it’s made of.

Methods for making knitted products

Home\Knitwear\Methods of making knitwear

Semi-regular and cut methods

The same knitwear can be cut or knitted along the contour of the pattern. When choosing a manufacturing method, you should first of all focus on the cost of raw materials and the expected quality of the product.

One of the ways to obtain a three-dimensional shape of parts of knitted products is knitting with a transition to another weave. The properties of knitted weaves are different, therefore, with the same number of working needles, the width of the knitted fabric will be different. Therefore, it is possible to obtain a part (or coupon) having different widths in different areas.

Semi-regular way

With the regular method of producing knitwear, a minimum of waste is generated, but productivity is relatively low. The cut method is more material-intensive due to inter-pattern lunges. A kind of compromise solution that allows increasing the productivity of manufacturing outer knitted products is the semi-regular method.

In this case, the knitted fabric is knitted in the form of a coupon, equal in width to the part of the product, with a worked bottom edge. A complex pattern shape is reduced to a simpler one - a rectangle, trapezoid, etc., then the coupon is trimmed according to the pattern: along the lines of the neckline, armhole, sleeve cap. Coupons are produced not only on flat machines, but also on round machines - in the latter case, you can get a product without side seams.

The disadvantages of the semi-regular method include the fact that it is less economical (waste ranges from 8 to 11%) than the regular one. In addition, the sections in the undercut areas (neck, shoulder sections, armholes) are joined using an overlocker - the resulting seams are coarser than with the regular method.

Obtaining a three-dimensional shape by combining weaves

There is another way to obtain a three-dimensional shape of knitted parts - this is knitting with a transition to another weave. The properties of knitted weaves are different: for example, ribbed weaves are characterized by loop stitches overlapping each other, press weaves - by an expanding effect due to loop outlines. Therefore, with the same number of working needles, the width of the knitted fabric will be different. Therefore, by combining weaves, it is possible to obtain a part (or coupon) with different widths in different areas.

The given shape of the parts is obtained on knitting machines using different degrees of elasticity of knitted weaves. Particularly rich possibilities are provided by the combination of weaves with different elasticity across the width. For example, if you need to give a skirt, part of a sleeve or a hat an extended shape or knit trim for products, it is enough to switch the knitting machine from producing one weave to another, taking care only that in those areas where the width of the part should increase, the elasticity of the weaves decreases.

You can use a knitting machine to knit a coupon for a woman's dress. The waist area of the product is formed through the use of an elastic weave. A wide eraser emphasizes the waist, while a narrow eraser creates a loose silhouette. In addition, when knitting an eraser, you can use an elastic thread, which will ensure greater stretchability of the product along the waist line. If you knit the lower part of the product with one weave, and the upper part with another, then the treated coupon dress will imitate a set of two parts - a skirt and a jumper. This compositional solution is achieved by switching from one type of knitting to another in one product. For example, the bottom of the product is smooth, the top is embossed or openwork; the bottom is knitted with a combined low-stretch weave, and the top with a lightweight weave; the bottom and top are made of yarn with different properties, etc. If you knit such a coupon on a circular knitting machine, the product can be made without side seams.

An example of a product whose shape is obtained by a combination of weaves is a beret knitted on a flat knitting machine. The narrowest and most stable section is knitted with an eraser or double stitch. This section of the beret is formed by the simplest press weave - half-fang. The area of greatest width is made with fang weave. After the fang section, there is again a half-fang section, and then an eraser.

It is advisable to use different weaves to create a shape when tailoring the part is undesirable. An example of such details is a collar, all edges of which, except for the edge of the sewing, are worked. In this case, the collar flap is knitted with a weave that forms a wider width than the stand. In this way, a decorative effect is also achieved.

When combining yarns and threads of different types in one product, it should be taken into account that bulky yarn creates sections of the part of greater width than less bulky yarn of the same structure.

Often, to create the required shape, an eraser of various repeats is used, which ensures uniform compression of the knitwear across the entire width of the part, in combination with other weaves. The advantage of the eraser and its advantage over other weaves is its greater elasticity and stretchability across the width. It stretches twice as much as satin stitch, so it is actively used when knitting cuffs, wristbands, sweater collars and other clothing items that must fit snugly to the human body and at the same time stretch well.

Thus, by using different weaves and types of raw materials, different arrangements of needles, you can obtain not only the desired shape of the product and its parts, but also an original patterned effect.

Cutting (cutting) method

When making products using this method, first a knitted fabric (flat or in the form of a tube) is knitted on a machine, then it is cut out according to patterns, like fabric, and the parts are sewn together. How well the shape of the product will correspond to a person’s figure depends on the degree of stretchability of the knitwear. Therefore, for low-stretch knitted fabrics, patterns are made with more complex contours, and for high-stretch knitted fabrics, they are simplified. The amount of waste during the cutting method, as well as when cutting fabric, depends on the configuration of the patterns, their size, the ratio of small and large patterns in the layout, the width of the knitted fabric, the type and length of the layout, etc. The smallest percentage of waste during cutting can be obtained by using patterns in the shape of the simplest geometric shapes - rectangle, trapezoid, etc.