Some synthetic fibers do not have inherent drape, so the sections of the cut pieces begin to fray. This problem adds work, but is not a reason not to use such materials.

Experienced seamstresses know how to process any type of fabric. But beginning craftswomen definitely need to study the technology in order to avoid difficulties and troubles in this matter, because the wrong approach becomes the cause of marriage.

There are several ways to deal with edge fraying. In this article we will tell you what to do if fabric sections are fraying. The easiest way is to use zigzag scissors, but this is not always effective, so you will have to work with your hands or do the processing by machine.

Hand overlock seams

It is easy to process the cut parts if the needlewoman has an overlocker in her arsenal. This machine was invented not so long ago, so dressmakers knew how to do without it, performing many finishing and connecting seams by hand.

This is not difficult to do; all you need is a regular needle and thread. Please be patient, as the process will take a long time if all sections of the product need to be processed.

The following seams are used for hemming:

1. Oblique. Stitches are made at an angle, moving from left to right, capturing 3 mm of fabric; there is no need to form loops. Use it on fabrics that are not very frayed.

2. Looped. Formed by pulling the needle under the stitch when it is not yet tightened. The distance between the punctures is adjusted depending on the degree of fiber separation. To hold them together, the seams are laid as tightly as possible.

3. “Twist” is best suited for highly stretchable, slippery and low-density pile fabrics. The needle is inserted in such a way that the cut is neatly twisted, forming a roller; the stitches are laid quite tightly to each other without forming loops.

If you need to hem the bottom of the product and at the same time overcast the edge of the cut, use a goat seam. Its shape is cross-shaped due to the fact that the upper and lower folded edges are alternately captured. In this case, the stitch is laid diagonally, then in the opposite direction, intersecting. Used on thick fabrics.

Without a face: processing seams and cuts in products made from two-layer fabric

The main characteristic feature of double fabrics is that their layers are separated. The creation of such fabrics is possible by means of a two-layer weaving, due to which two fabrics are formed at once, connected to each other.

Moreover, this method allows you to combine two fabrics of different composition, texture and color in one fabric. This combination is used to achieve spectacular contrasts in one product, for example, in a coat - on the lapels, collar, lapels, belt.

In products made from two-layer fabrics, the details are not duplicated; they do not have a lining, double details, such as a lining, an internal part of the collar stand and an upper collar. They are sewn in a special way, in which more than 50% is devoted to meticulous handwork! All seams on the outer layer of the product are made on a sewing machine, and on the inner layer - exclusively by hand, or vice versa. Also, all external open cuts are processed manually.

Products made from double fabrics are especially light, but at the same time very warm, extraordinary, with a peculiar optical illusion of the perception of the model. Each piece is a work of fine embroidery. To achieve a perfect result, high precision is required when performing sewing work at every stage. Then you can really boast of real exclusivity.

When choosing two-layer fabrics, you should give preference only to high-quality materials from premium raw materials - alpaca wool, cashmere, pure sheep and camel wool. This is due to the large labor costs that are inevitable for such a sewing project.

Alpaca is a priceless gift of nature

What is cashmere: features of luxury wool fabric

Processing of two-layer fabrics has a number of features. All seams, including cuts along the bottom of the product and sleeves, along the edge of the collar, are made “clean”, in other words, closed, which allows the finished item to be worn on both sides.

How to cut parts from two-layer fabrics

Before you start cutting out the parts of a product made from two-layer fabric, sew a mock-up of the model and make all changes and adjustments to it.

Cut out the details of the product with allowances for all cuts - 1 cm.

How to decate coat fabric with cashmere

Preparing parts for grinding

Determine the width of the future allowance:

in thin two-layer fabrics, the finished seam width will be approximately 0.5-0.7 cm; if the fabric is thick, the seam allowance and seam allowance will be larger.

Fix the layers of two-layer fabric together:

along the edges of all parts at a distance of 1.5 cm from the cut, lay a basting line on a sewing machine with a maximum stitch length.

Depending on the thickness of the fabric, the basting stitch may be located at a greater distance from the cut, and the width of the finished seam will accordingly increase.

After processing the seam, the basting stitch will need to be removed.

Layer the fabric:

Using small scissors with sharp tips, layer all the sections exactly to the basting line. This is a necessary condition for making smooth seams of the same shape and thickness.

How to sew parts from two-layer fabrics and process seams

Seams pressed

Place the pieces together and sew the sections of only the outer layers of the fabric on a sewing machine, departing from the basting line by approx. 0.7 cm (in my case this is half the width of the foot).

In this case, the cuts of the internal layers of the parts should under no circumstances fall under the stitching.

Carefully press the seam allowances of the outer layer.

Turn the sections of the inner layers inward and iron them (or pin them), with the folds positioned end to end.

For convenience, you can baste allowances.

Hem the folds of the inner layers by hand using blind stitches.

Basic hand stitches

Remove the basting stitch.

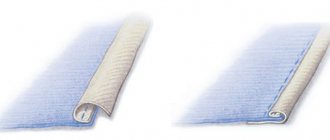

Lightly press the seam on both sides. It will be slightly convex, shaped like a small roller.

Pressed seams

Processing two-layer fabrics with a pressed seam creates a more pronounced decorative roll, in contrast to pressed seams.

Determine which part the seam allowances will be directed towards, for example, towards the back or towards the front.

After performing the basting stitch, layer the cuts on only one piece! For example, cuts of the side seams of the back.

Fold the parts together and stitch them, stepping back from the basting stitch 0.7 cm, capturing only the cut of the outer layer of the part, towards which the seam allowances will be directed.

Trim the seam allowances to 0.7 cm and iron towards the inner layer of the part.

Tuck the cut of the inner layer of the part inward so that it overlaps the stitching line of the parts. Pin or baste and iron.

Hem by hand using blind stitches.

Remove the basting stitch.

Processing sections of parts made of two-layer fabrics

Cuts along the bottom of the product, sleeves, along the edge of the hem, collar or neckline without a collar in products made from two-layer fabrics are processed in the same way, regardless of which method of seam processing you chose, pressed or pressed.

Along the open edges of the parts, place a basting stitch with a maximum stitch length at a distance of 1.5 cm from the edge (in thicker fabrics - 2 cm).

Using small, sharp-tipped scissors, layer the open sections exactly to the basting stitch.

Turn the sections inward exactly to the basting line, baste and iron.

Hand sew the folded sections together using blind stitches.

Remove the basting stitch.

Processing corners of parts made of two-layer fabrics

Along the open edges of the parts, at a distance of 1.5 cm from the edge, lay a basting stitch on a sewing machine with a maximum stitch length.

Turn to the other side exactly so that the stitch forms a right angle.

Use small, sharp-tipped scissors to separate the exposed sections.

Turn the sections inward exactly to the basting line, baste and iron.

In the corners, turn the cuts in one direction.

Hand sew the folded sections together using blind stitches.

Remove the basting stitch.

Ready to use

Few brands can boast of finished products made from double fabrics, sewn using original techniques. The fact is that the “invisible” method of processing seams requires not only skill, but also a lot of patience from the craftswoman. Each stitch of a closed seam, made by hand, must be in its place, and you will have to make a lot of them in one product. It can take a professional craftsman up to three days to create one coat!

Fashion designers of the famous Italian brand MaxMara were among the first to actively use this technique.

And today they are the absolute favorites, creating models from two-layer fabrics with closed seams, made entirely by hand.

For several years now, more and more new clothing models have been appearing in MaxMara collections, made using such an interesting seam processing technique.

How to sew a skirt from two-layer fabric based on Max Mara

Mostly coats, impeccable and incredibly elegant. Why not get some inspiration for your own project?!

Some tips:

✂ If necessary, reinforce individual seams, for example, shoulder seams, with a narrow strip cut on the bias from thin durable fabric, adjusting it to the seam allowance.

✂ If the two-layer fabric is two-color or the layers differ in composition and texture, determine which layer will be sewn with closed seams by hand and which by sewing machine (small samples will be enough).

✂ Try to select the threads exactly in tone so that they are not visible.

✂ If the fabric has a directional pile or pattern, pay attention to the fact that this direction must match in the seams and in the details of the product.

✂ To sew a basting stitch, use threads of a contrasting color.

Author of the master class and photo of the process: Yulia Dekanova

Samples and photos of fabrics for the master class provided by: @tkani.andreana

Coat photo: Max Mara

Machine operations

In order for the product to serve for a long time, and the quality of the work performed to be at its best, the edges of the parts must be processed in a suitable way.

Even if you don’t have an overlocker, but just a sewing machine, you can perform these operations:

- Straight stitch with hem. The edges of the cuts are folded and stitched, setting the stitch length to about 2 mm. On thin fabrics, for example, chiffon, silk, re-hemming is done and the seam is laid again. The product looks perfect and neat.

- Zigzag seams are performed by many machines; even a manually operated Podolskaya can be used for this purpose; you just need to buy a special attachment. This stitch is used for finishing edges instead of an overlock stitch. The thinner the fabric, the tighter the stitches need to be placed.

- Processing with bias tape. This method is used for sewing branded clothing. All open cuts are processed not with an overlock stitch, but with finishing tape. This distinguishes the quality of the products. Execution requires skill, but everything can be learned. Sections of lace and other delicate fabrics are processed in this way, since this is the only way to do the job accurately.

The sewing seam is used in the manufacture of bed linen, as well as for processing sections of thin materials. First, the parts are connected with the wrong sides facing each other, a seam is laid on the front side of the product, then they are turned inside out and stitched again.

As you can see, you can process the cuts by hand and using a straight-stitch sewing machine.

Let's get acquainted with materials that do not require processing

It is easiest to work with fabrics whose cuts do not fray. Modern technologies have made it possible to produce non-woven materials, which means that the fibers in them do not separate and therefore do not fray. Cutting clothing items from them is a pleasure, and assembly is even easier, because you only need to lay connecting seams.

Let's list these fabrics:

- artificial leather and suede;

- some types of knitwear;

- fleece;

- felted loden;

- neoprene.

Cardigans, which are sewn without finishing the edges of the collar, sleeves, or the bottom of the product, have come into fashion. The fabric does not fray, so you can do without overcasting stitches.

How do fashion designers use sewing?

The fabric is ideal for creating an accent, using any visual effect, adjusting the figure, or hiding a flaw. She helps out craftsmen when working with women's and children's clothing, taking part in sewing the following products:

- Christening sets for newborns are dresses, bodysuits, shirts, socks, headbands and other elements of elegant children's clothing for the baptism ceremony;

- Women's summer sundresses, blouses, jackets are infinitely comfortable in extreme heat if they are made from natural fabric using sewing. They look elegant and neat; they are worthy models for cruises, office style, everyday life, and festive events;

- Bed linen and home textiles with openwork details are a truly luxurious gift for the home. Many fabrics are suitable for draping pillowcases, curtains, towels, towels, which are not necessarily used in everyday life, but simply decorate the interior;

- Boho themed clothing is one of the styles that is characterized by lightness and layering. Sewing correctly conveys a woman’s mood and brings tenderness and airiness to her image. The fabric shimmers beautifully in the light and floats effectively when the wind blows;

- Sewing motifs are also used when sewing and finishing wedding clothes. Decorative fragments involving fine embroidery, lace, and perforation add volume to even a laconic dress;

- Underwear and nightgowns are an opportunity for the craftsman to express his imagination. Women's underwear made from sewing looks like an airy cloud, it is safe for the skin and health in general, and is great to wear in the summer.

Despite the subtleties and peculiarities of sewing, the fabric is pliable and not capricious in the hands of even an inexperienced craftsman. Thick fabrics make good summer skirts and simple-style sundresses.

Working with organza and satin: making decorative elements

Clothes for special occasions, for example, wedding and ball gowns, are trimmed with fabric flowers. Organza and satin are best suited for these purposes. They hold their shape, the petals are at the same time tender, but not deformed. Working with these fabrics is not easy - craftswomen know how much they fray. Processing with a needle and thread is not a suitable option for making flower buds.

There are special tools and devices for this. Cut out parts from organza using hot scissors (electrical device), and from satin using a needlework needle. The petals are shaped using special attachments - bulbs. In this way, even small parts are obtained whose edges do not crumble.

Sewing is a fascinating type of needlework; it requires patience and perseverance from the craftswoman. But if you set yourself the goal of getting a beautiful, exclusive product, be it an element of your wardrobe or decor, you should not regret the time and effort spent. The result will exceed expectations if the work is done carefully.

Product care

There is no need to be afraid of sewing when caring for fabrics. Despite their lightness, delicacy, and many decorative accents, they are quite durable. When washed, the patterns retain their shape and do not change in diameter, and accordingly, the fabric holds its design well.

If possible, it is better to wash the product by hand, do not wring it too hard, and hang it carefully to dry to avoid severe creasing and creasing. But clothes made of thick fabric can be washed on a delicate cycle at low temperatures in a machine. This is important to avoid shrinkage of the natural cotton structure.

Don't forget to look at the range of our Italian sewing from the Sewing category.

Happy sewing! Sewing fabric catalog